Introduction

This system was designed and manufactured for a company producing high-reliability

Video

Gallery

Features

Goal:

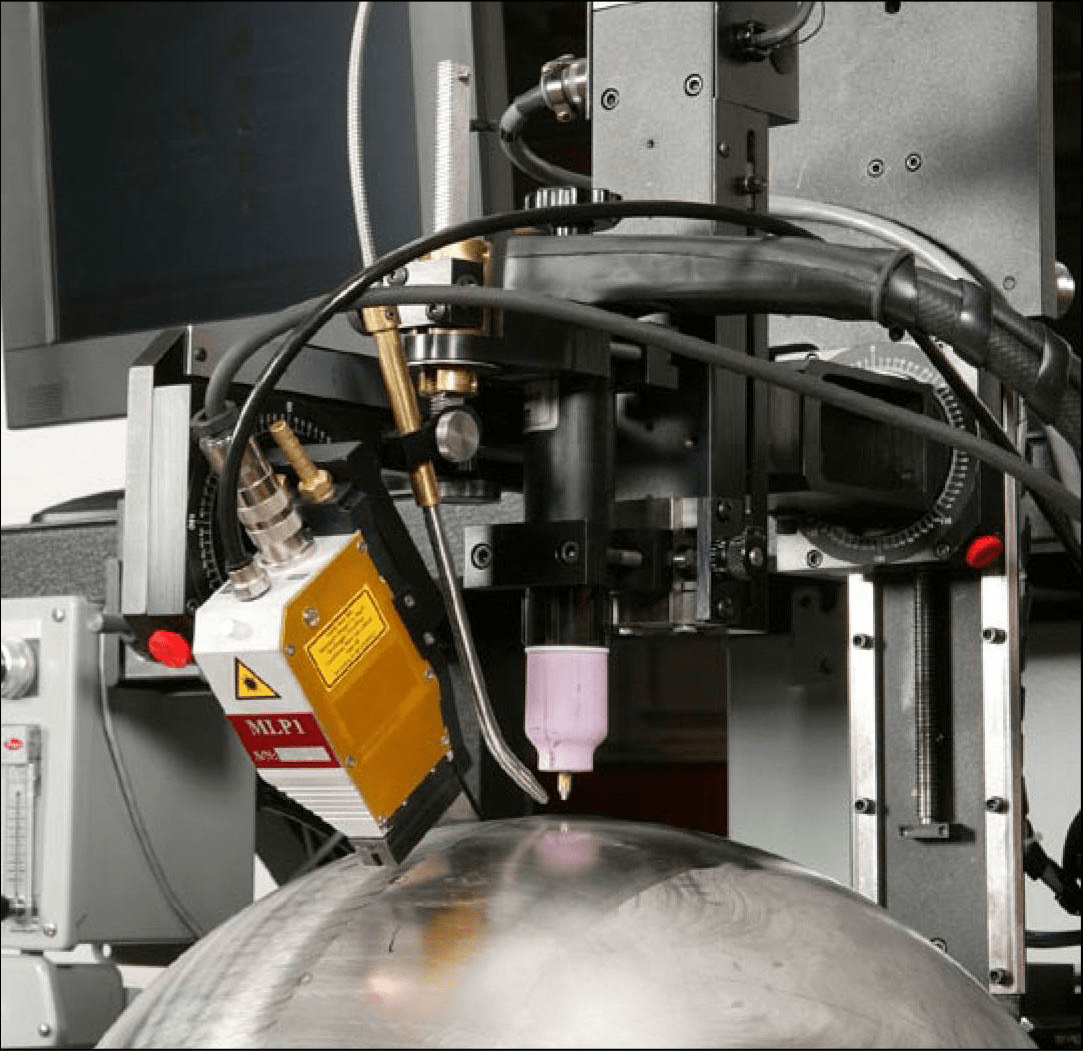

Design a Computer Controlled Automatic Welding Station that would reposition the torch, laser track the weld seam and produce x-ray perfect welds with no operator present during the Multi-Pass Tig Weld process. The system memory stores all the process parameters to enable rapid part change over.

- 300 Ampere Computer Controlled P.S.

- 3 Axis C.N.C. Controlled

- Laser Seam Tracker

- Cold Wire Feeder

- Arc Distance Control

- Dual Stage Quick Purge

- Network Interface

Specifications

Applications

Application:

- Short Run – High Volume Pressure Vessels for Fire Extinguishers and Hydraulic Accumulators

Industry:

- Aircraft / Aerospace

Requirements:

- Operator less system operation to produce highly consistent x-ray clear full penetration Tig welds.

Ask our experts about your unique challenge

Previous Product

AWS-150/6100 System Vertical Welding Station