Over 35 years of innovation and quality.

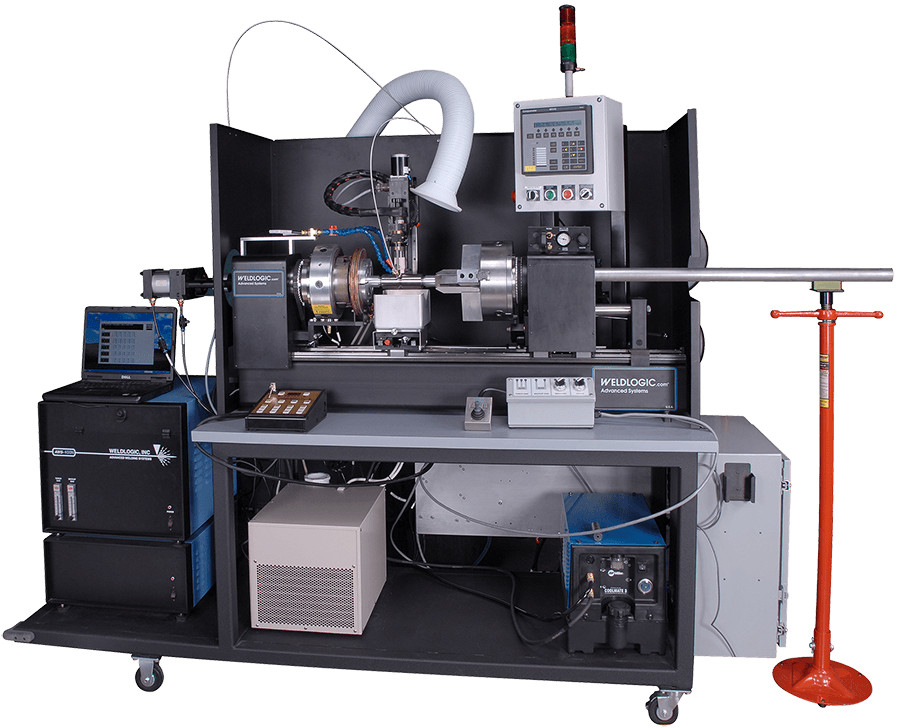

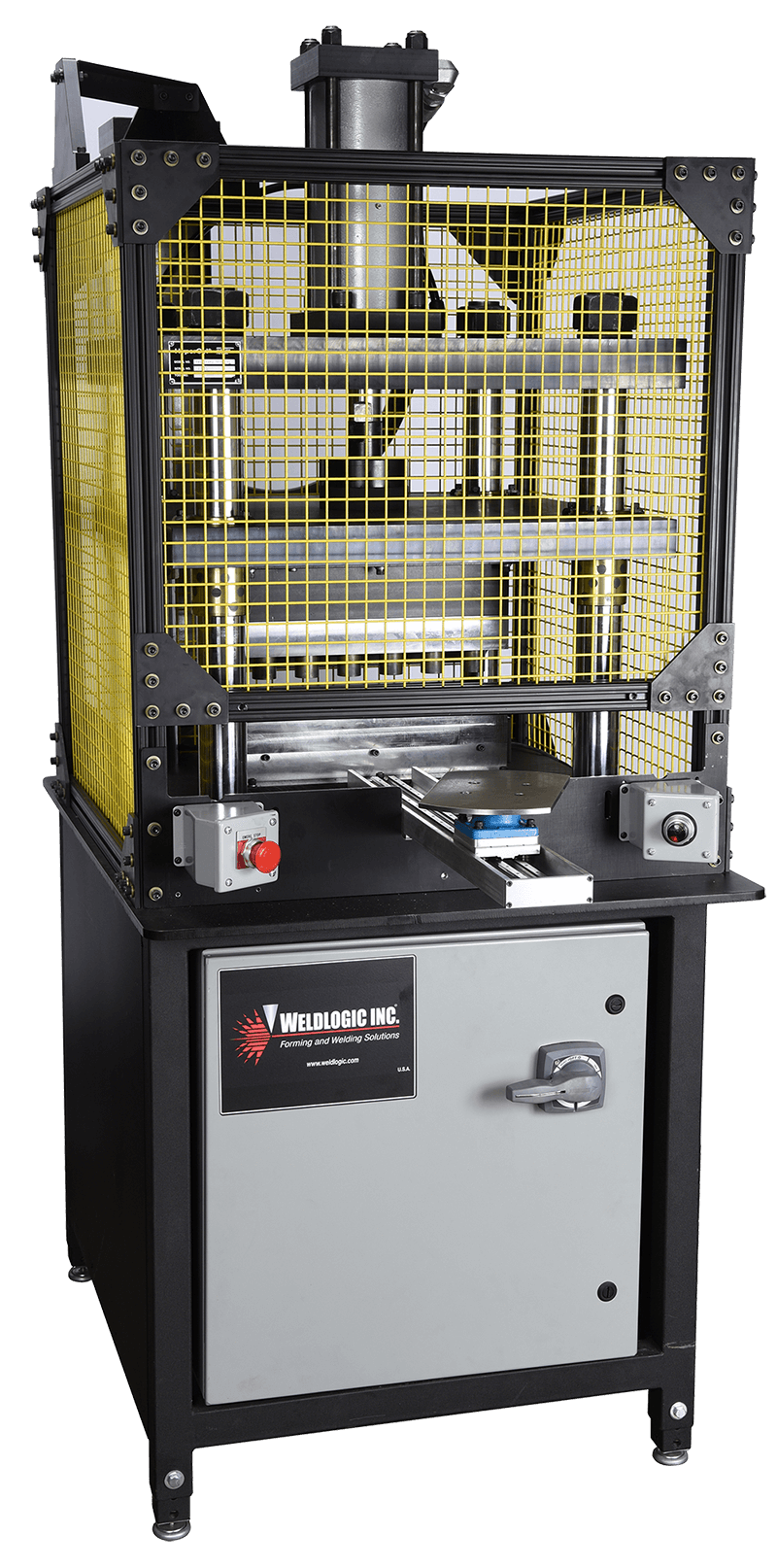

In today’s competitive environment, automated welding systems give manufacturers a way to stay ahead of the competition. Through constant innovation, Weldlogic continues to develop and produce automated welding processes that deliver the speed, quality and precision you require.

After 30+ years and over 5,000 robot integrations, welding challenges are a core competency at Weldlogic. Providing both custom and turnkey solutions, our organic approach to developing client projects begins with an analysis of your process needs and requirements. The result is an automated welding solution that is finely tuned to accelerate your ROI.

The Weldlogic Facility

Come visit us anytime. Meet our experts and test our solutions before you make a decision.