Introduction

Challenge:

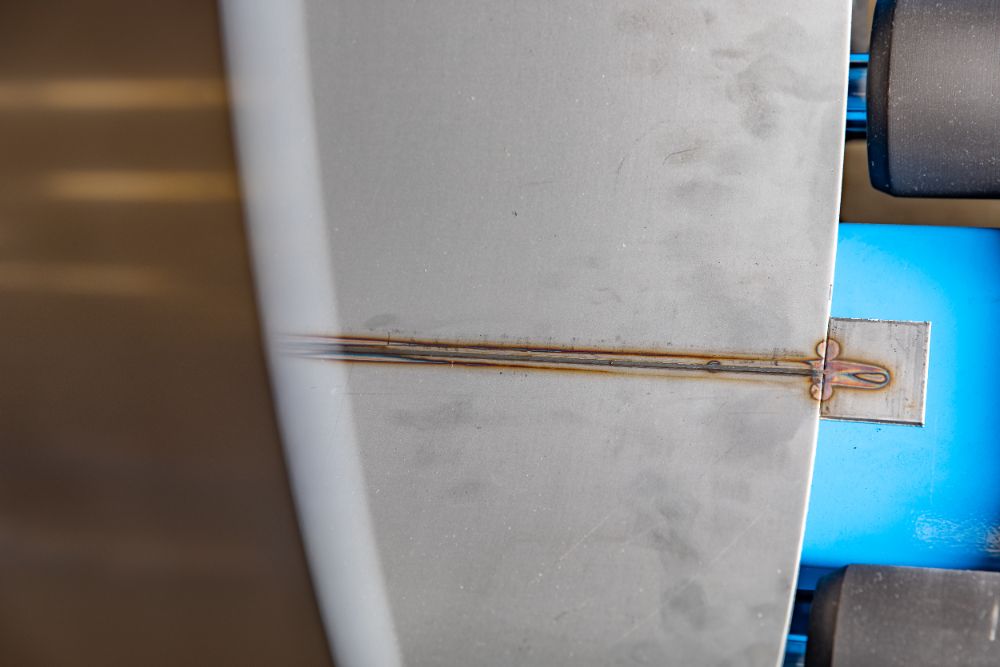

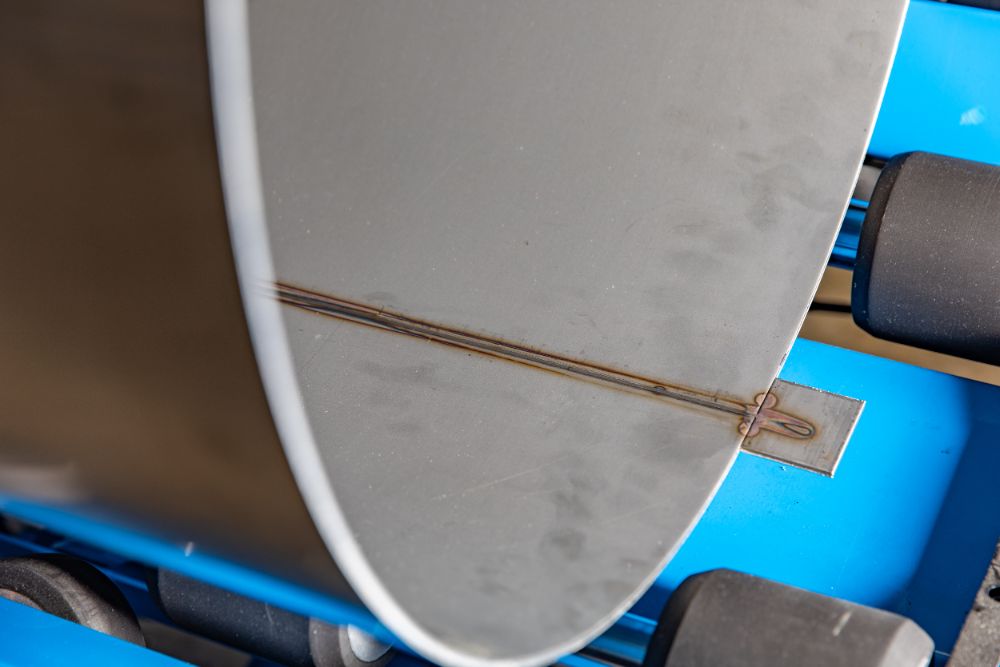

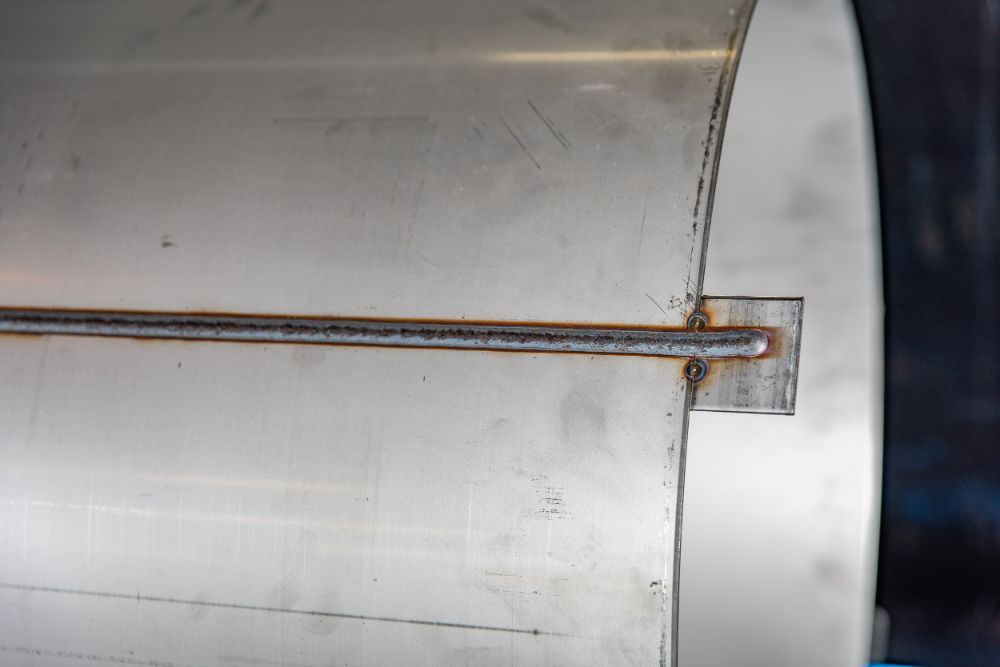

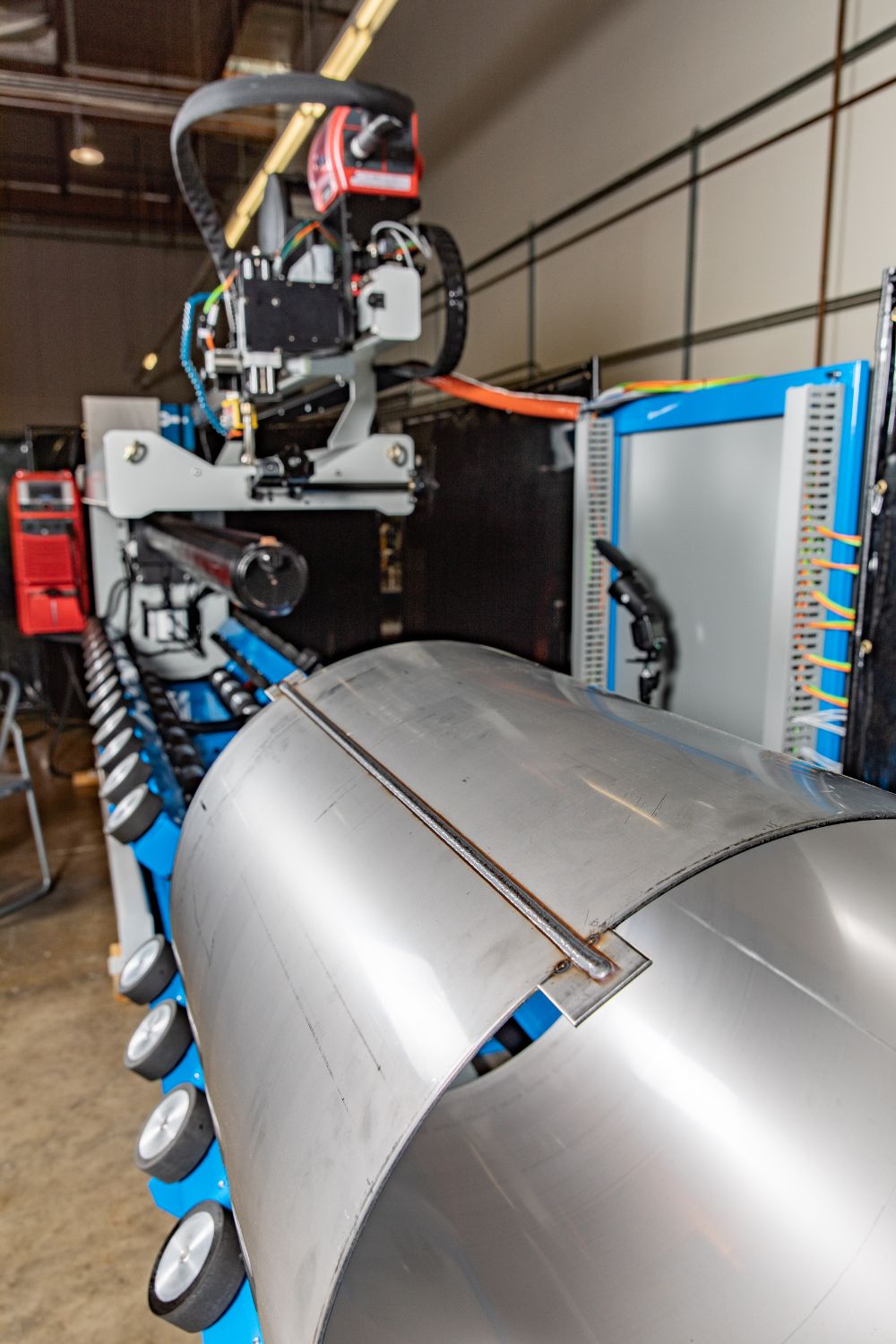

Eliminate the high physical stress levels of loading and unloading heavy tanks into a seam welder 18 hours per day and eliminate the highly skilled operator.

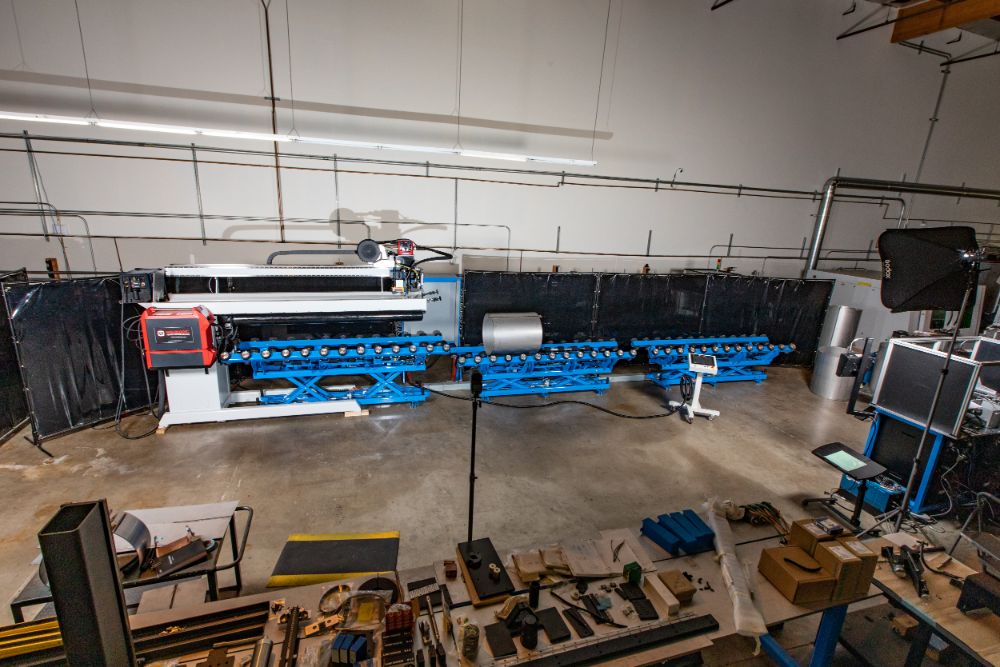

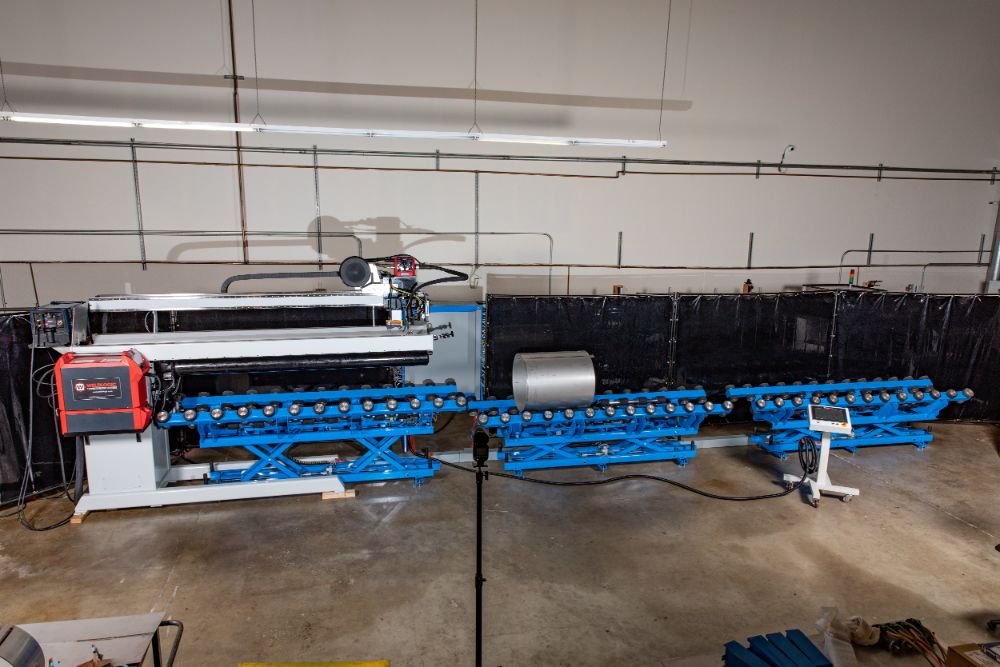

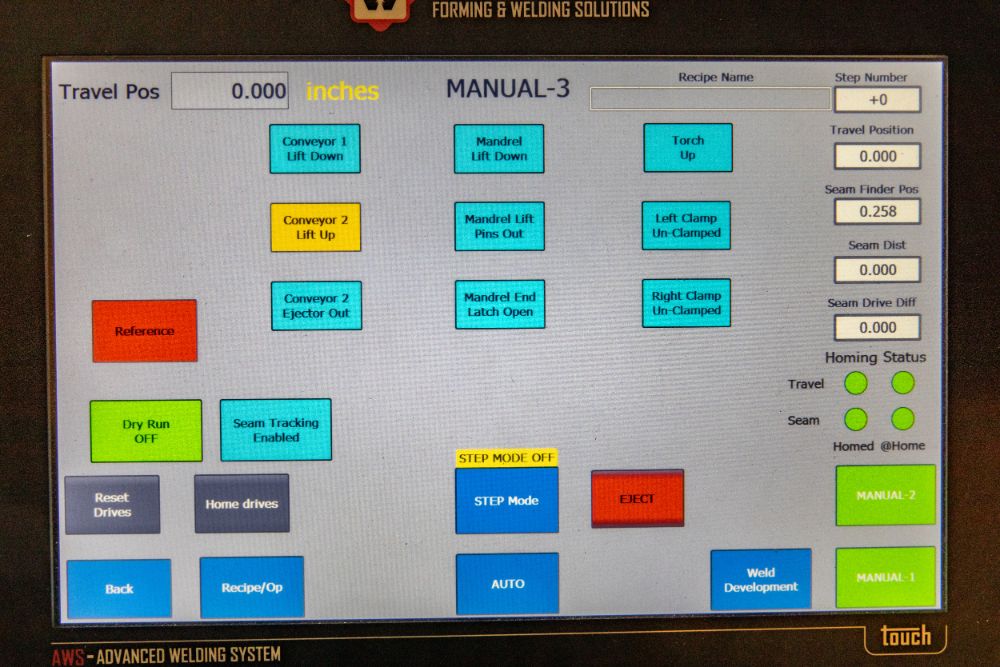

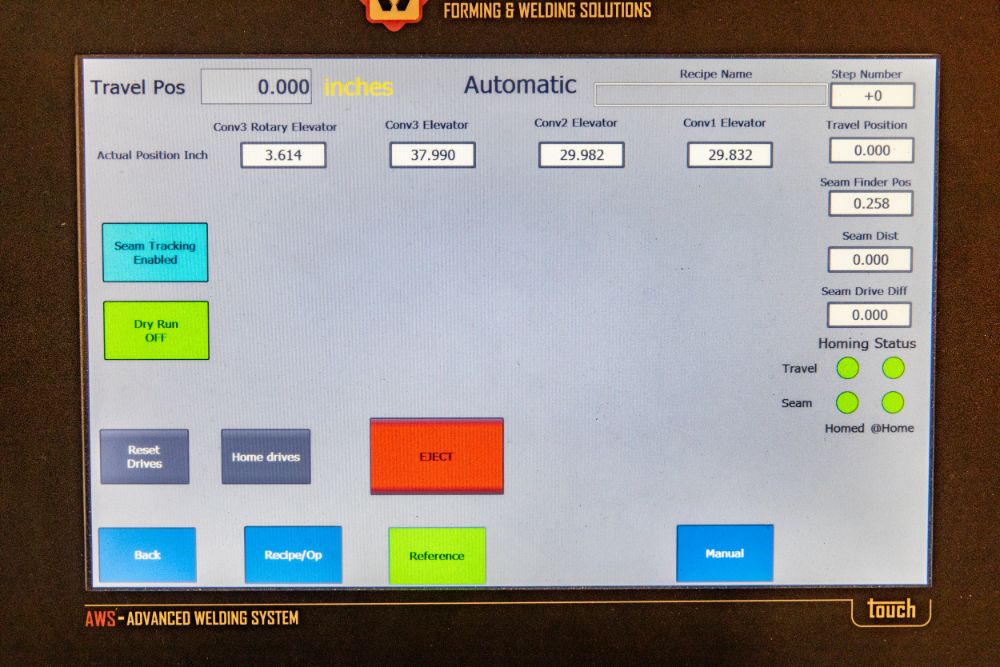

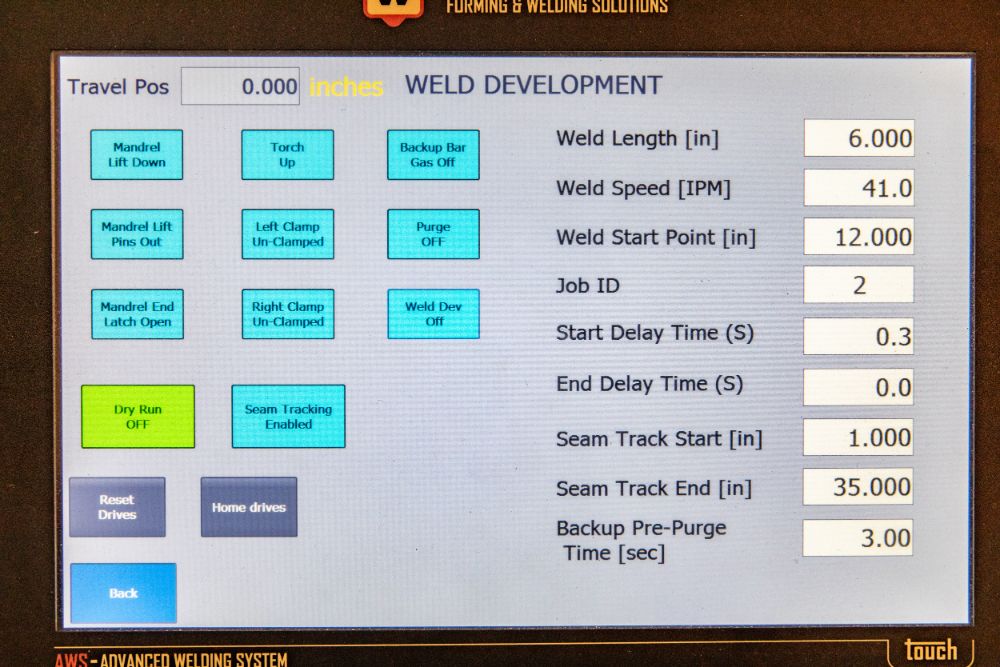

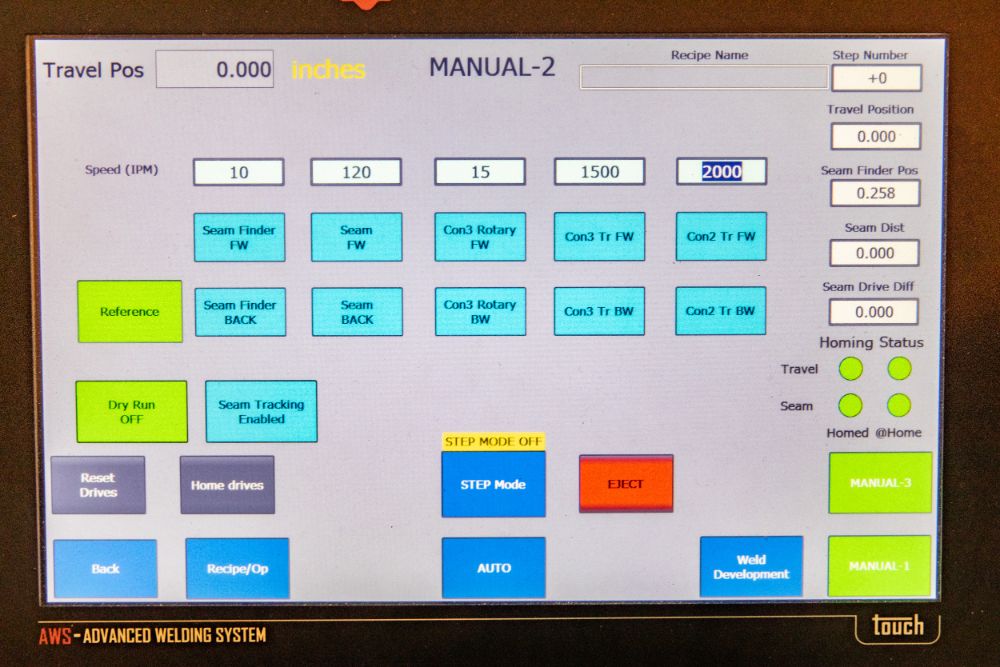

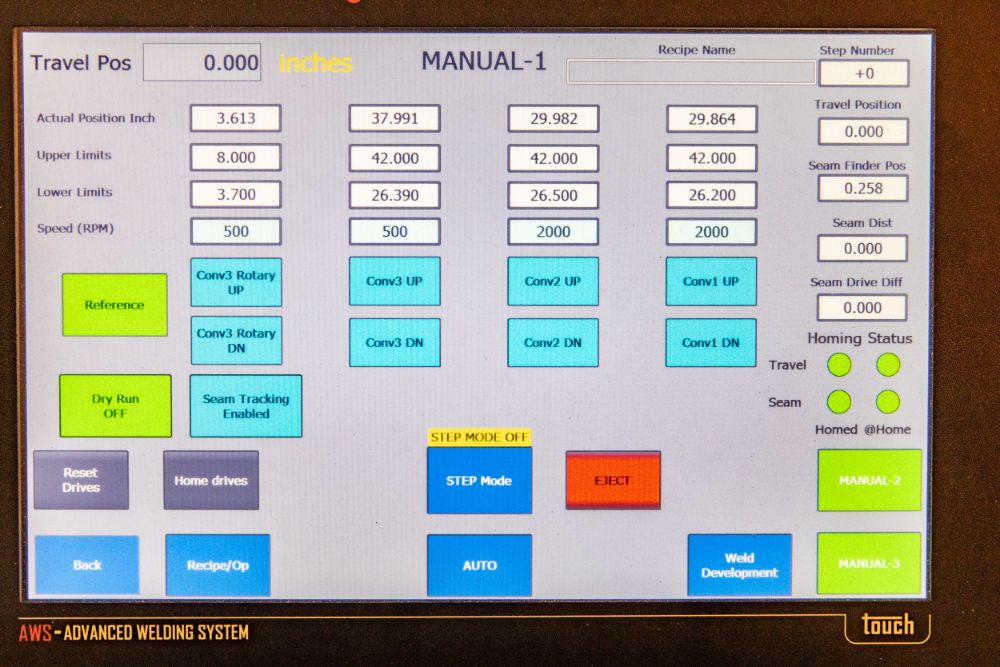

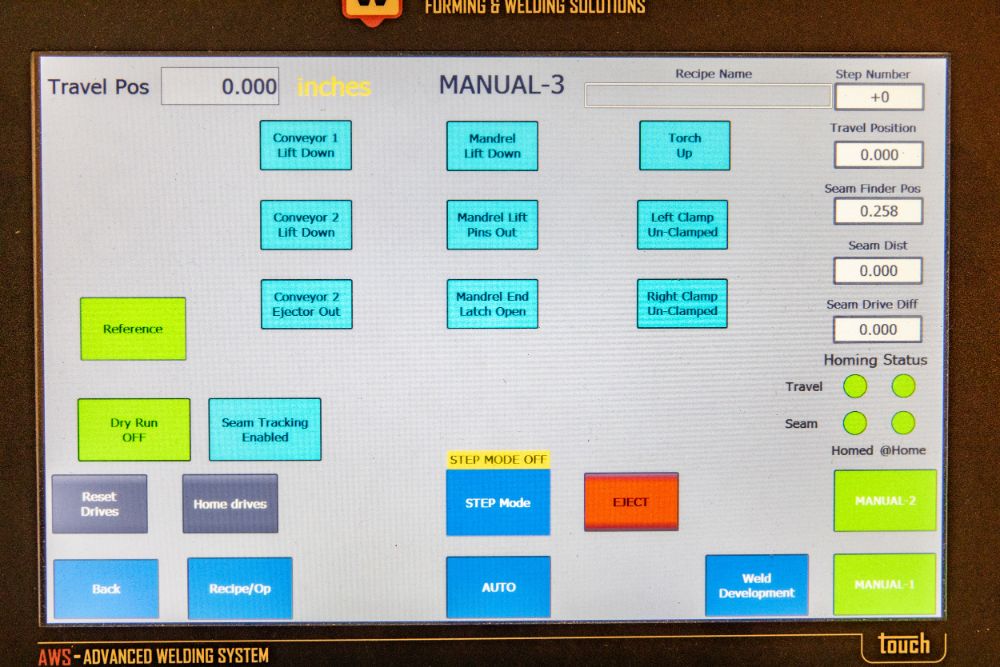

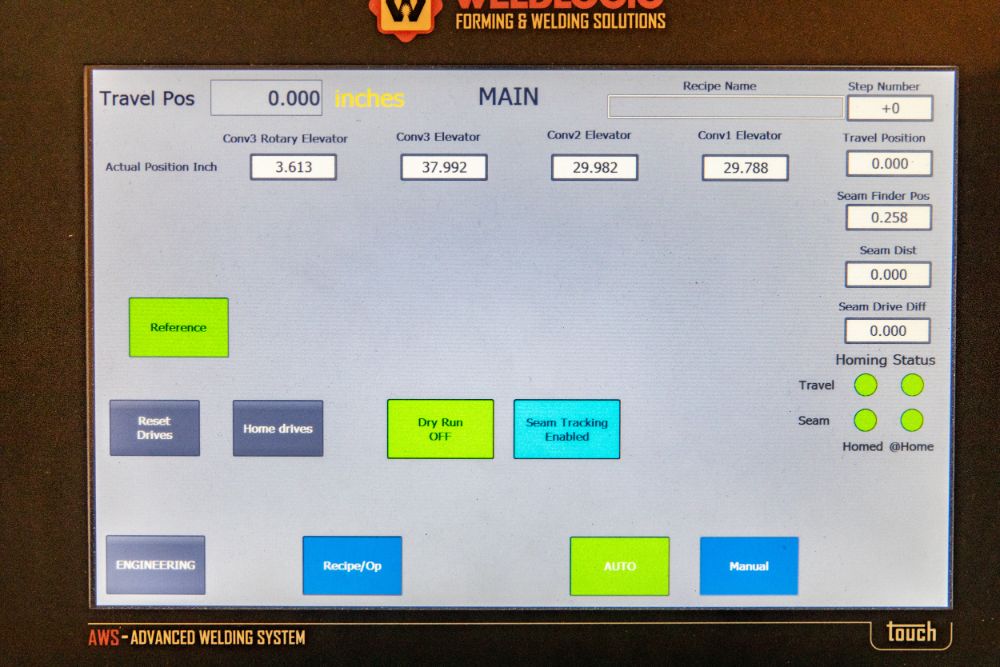

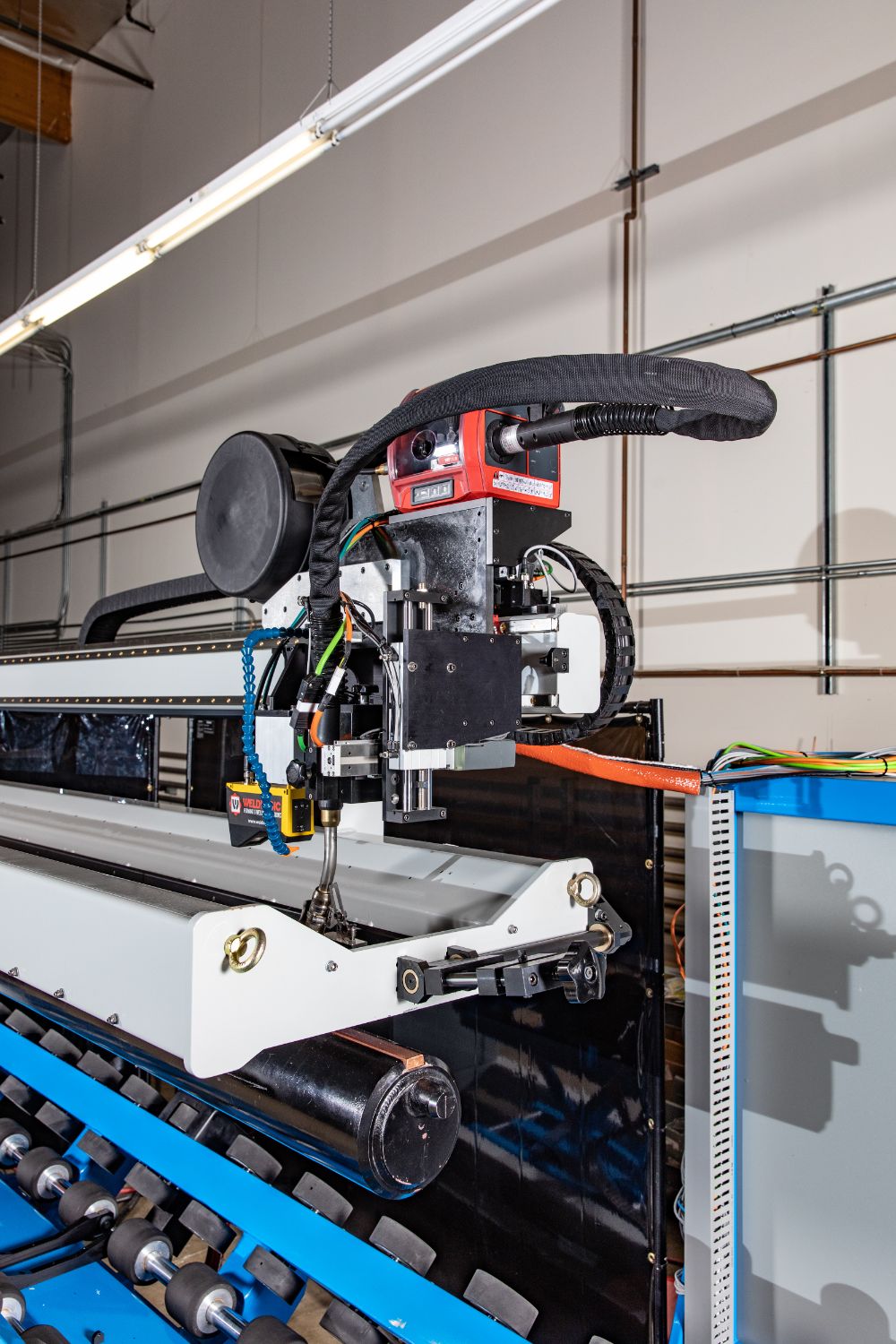

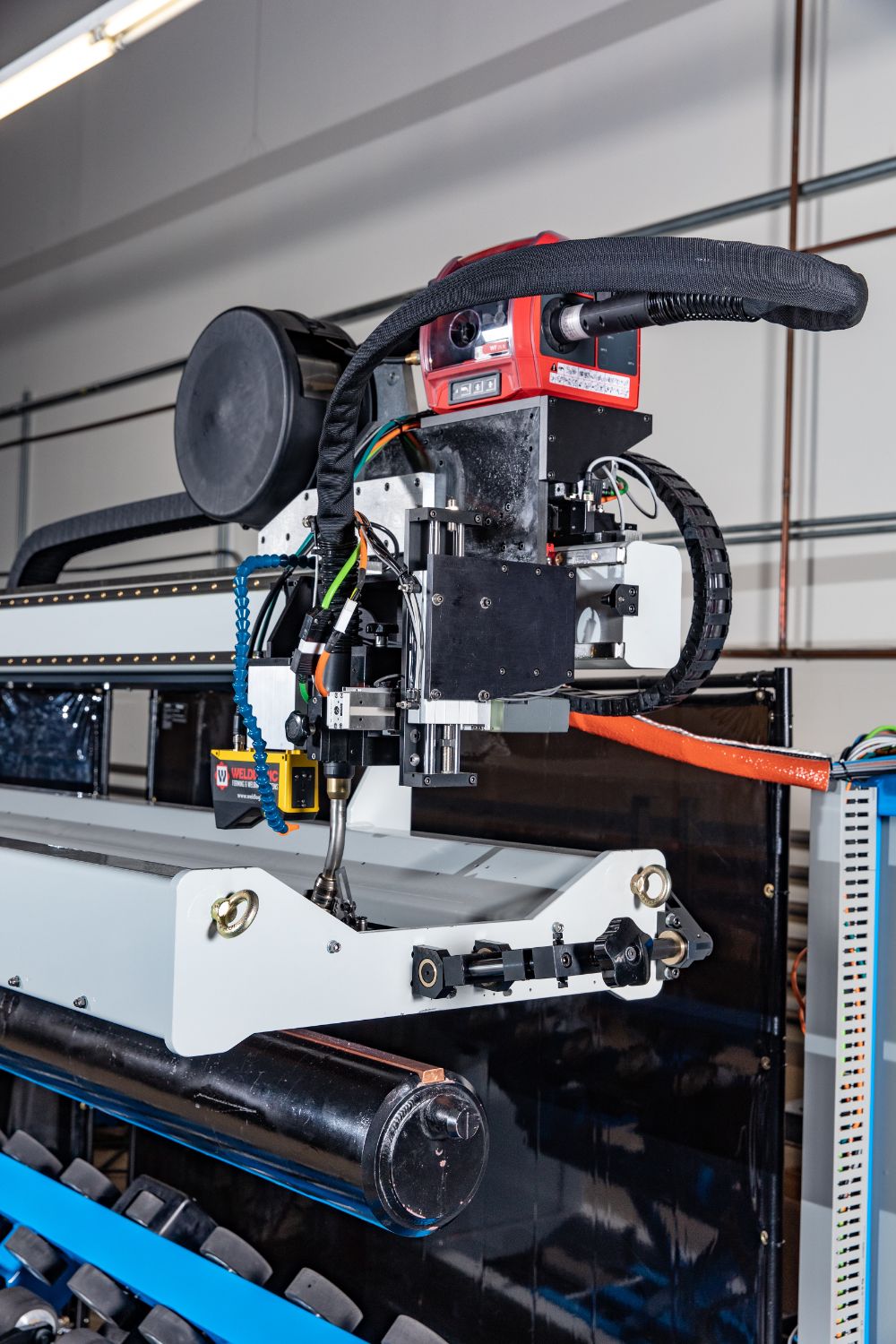

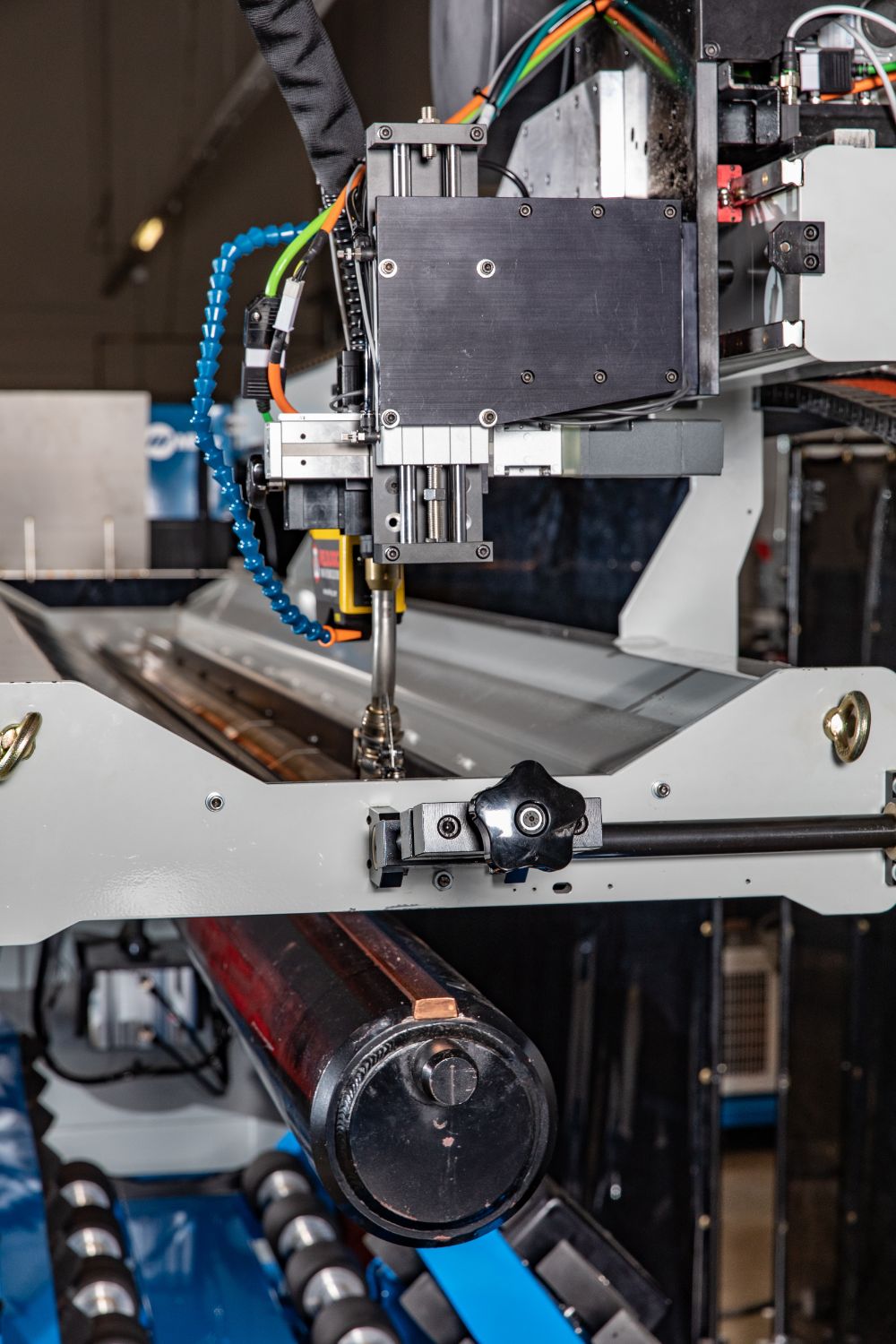

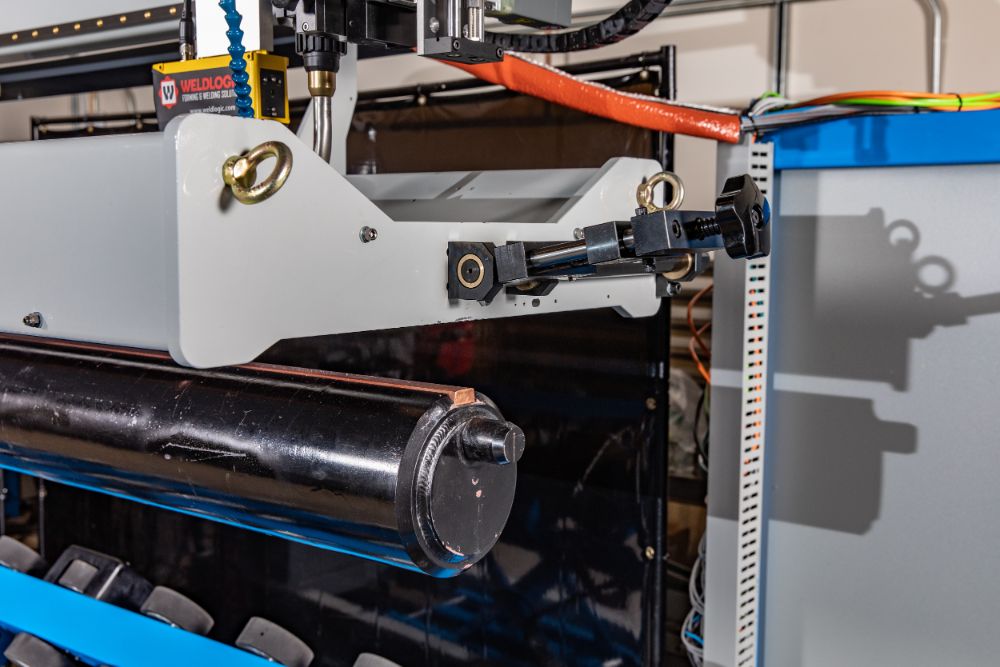

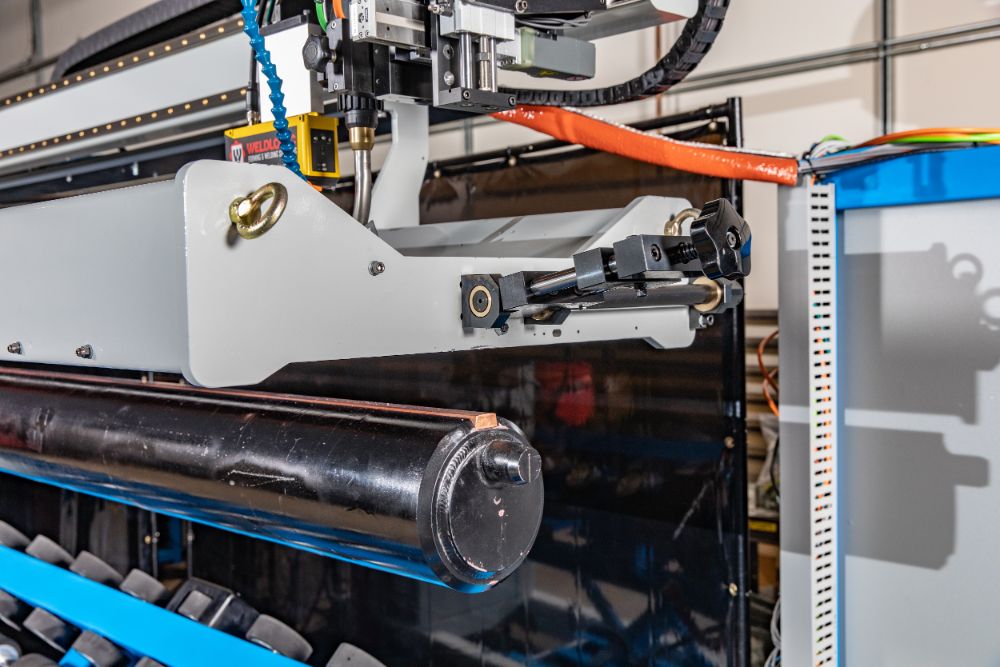

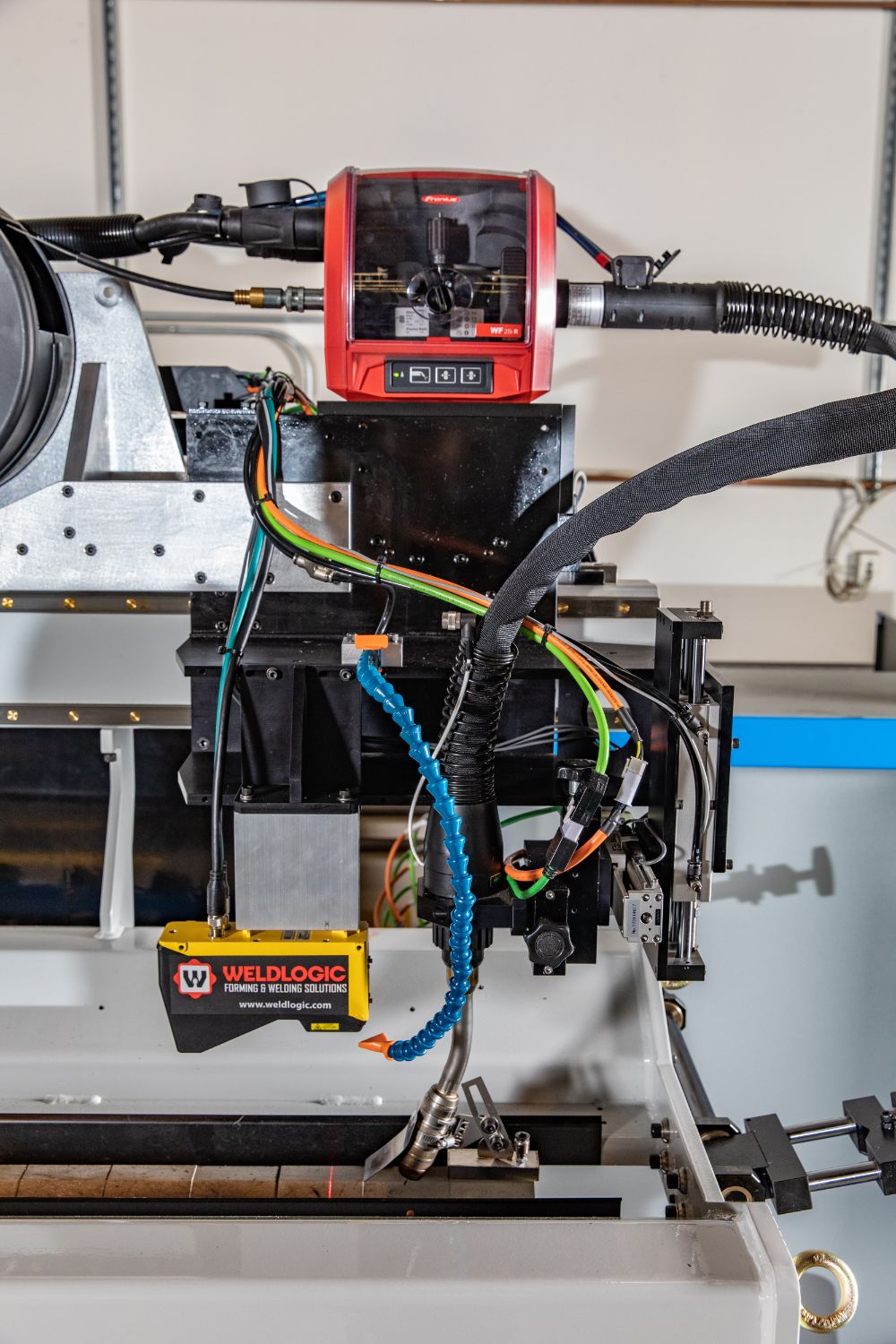

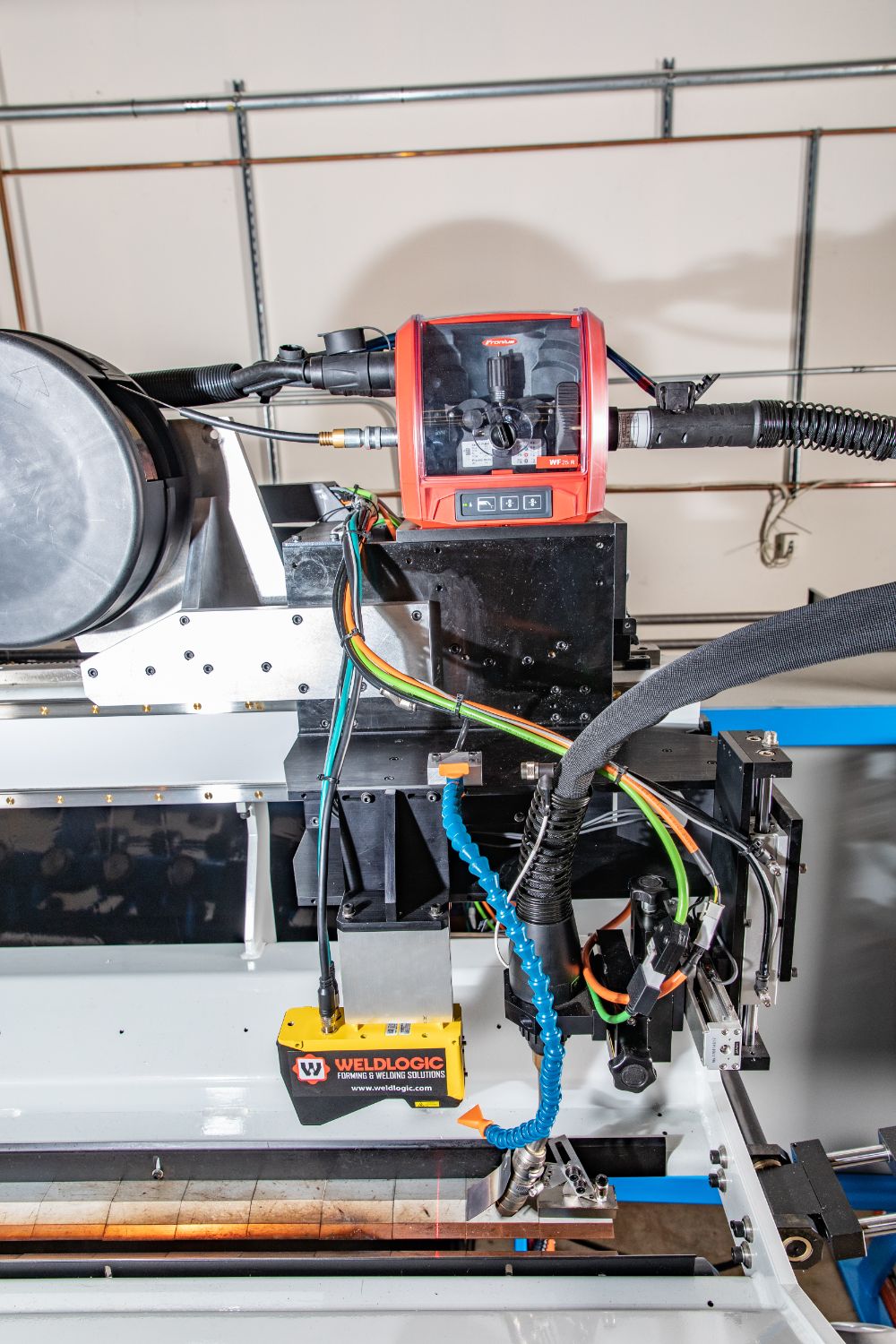

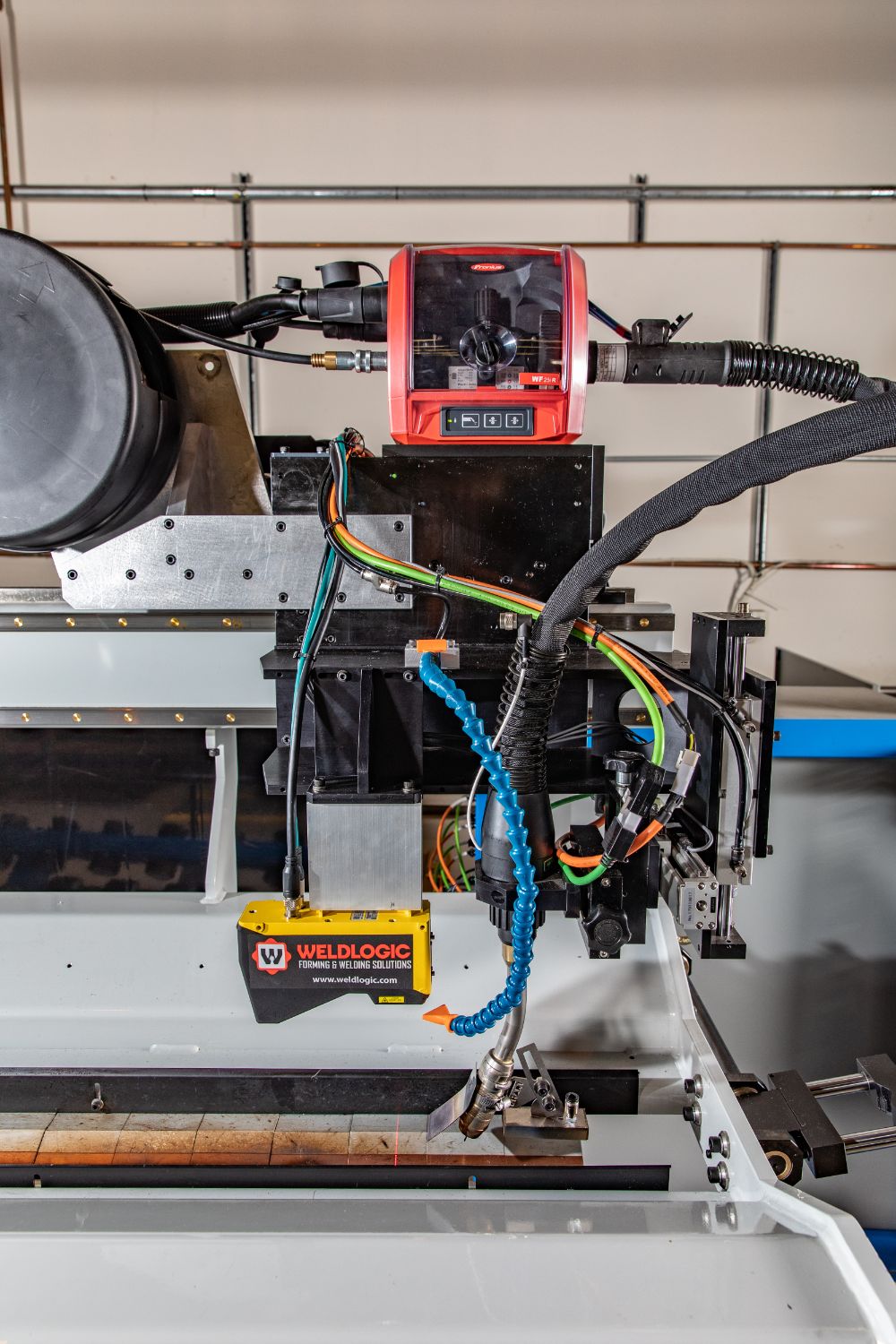

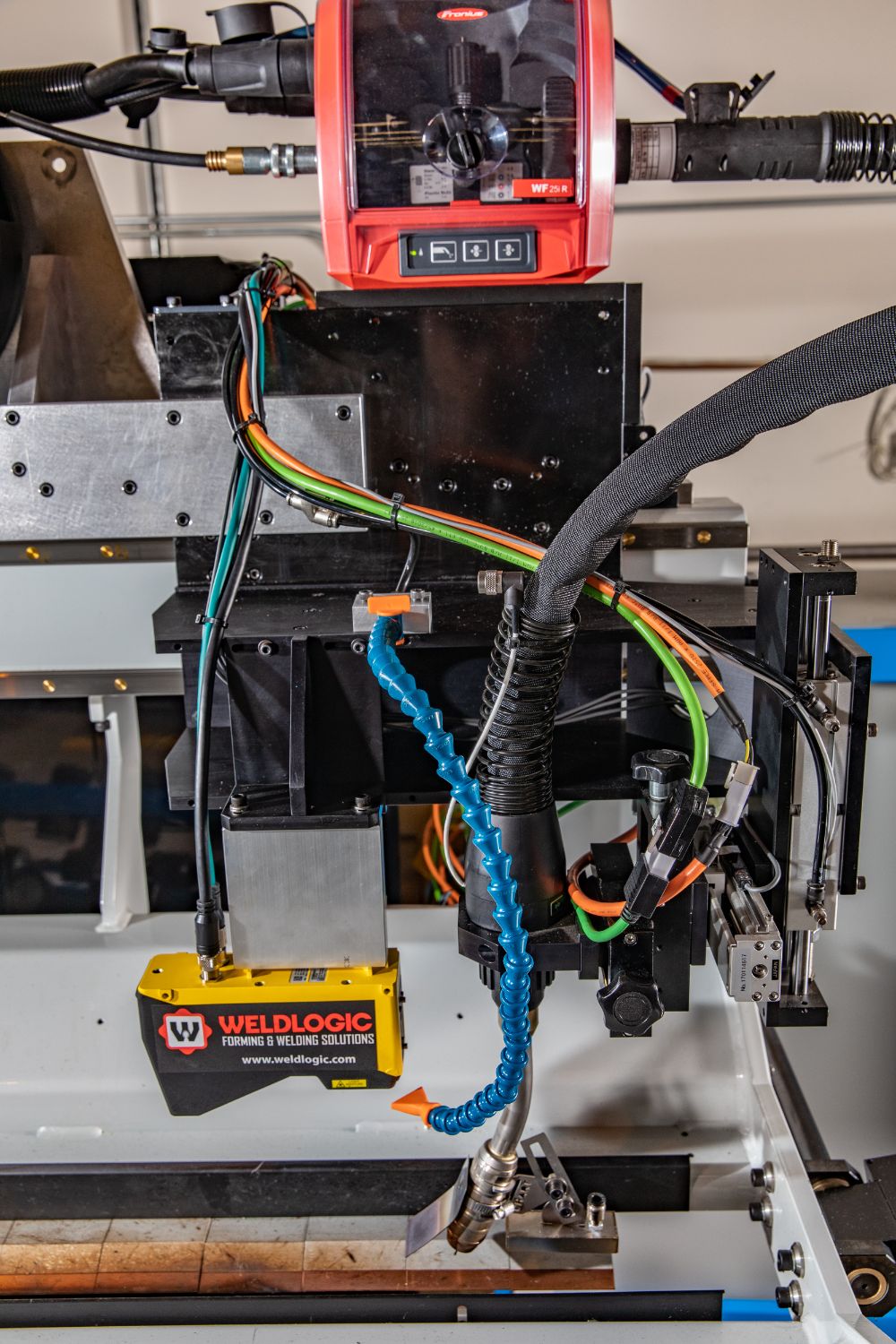

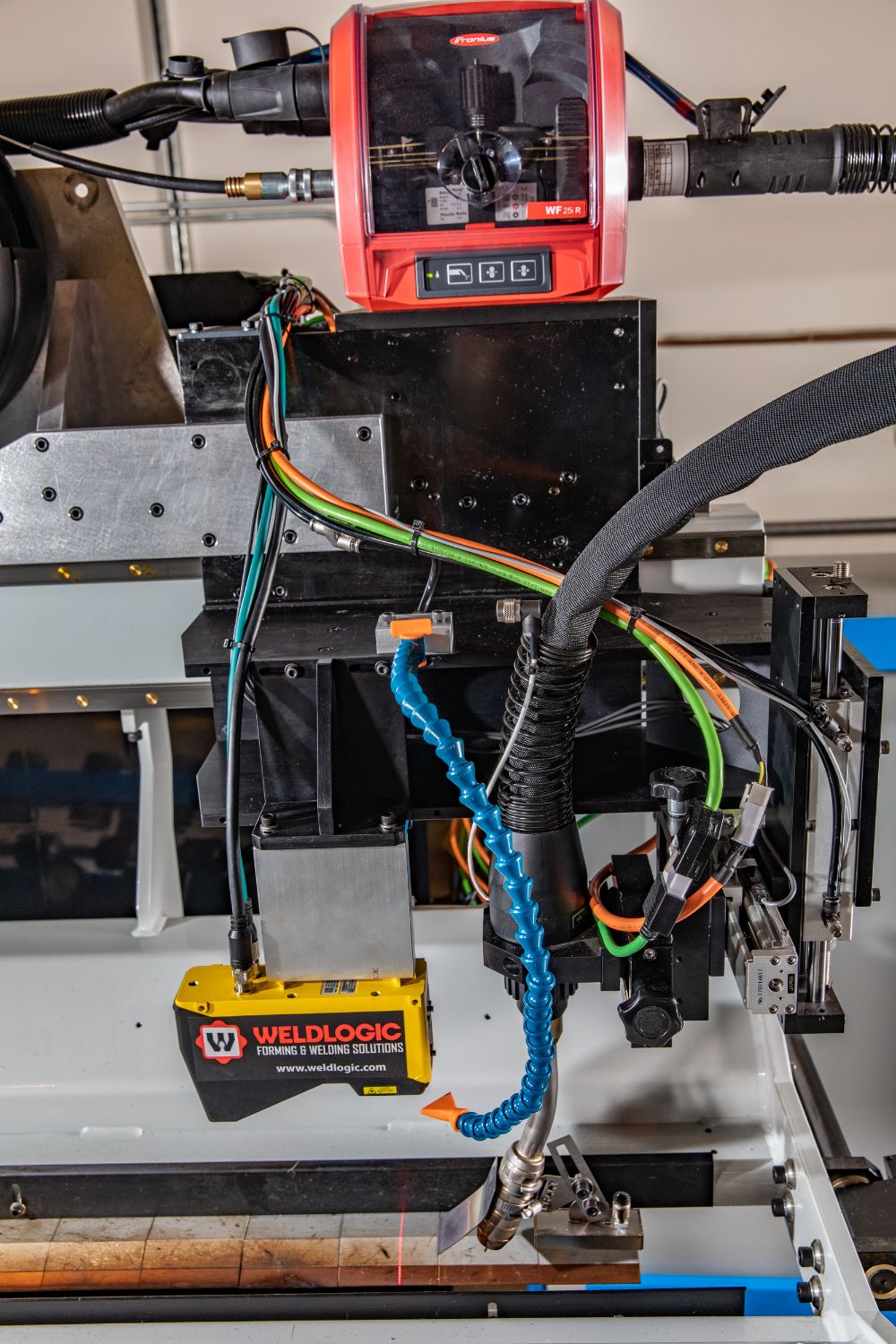

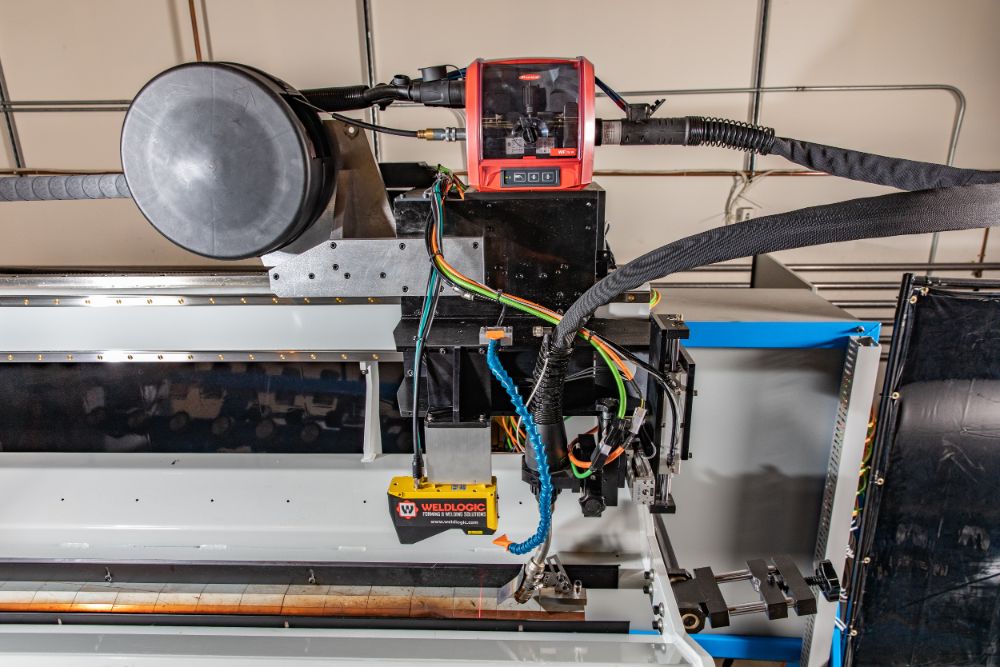

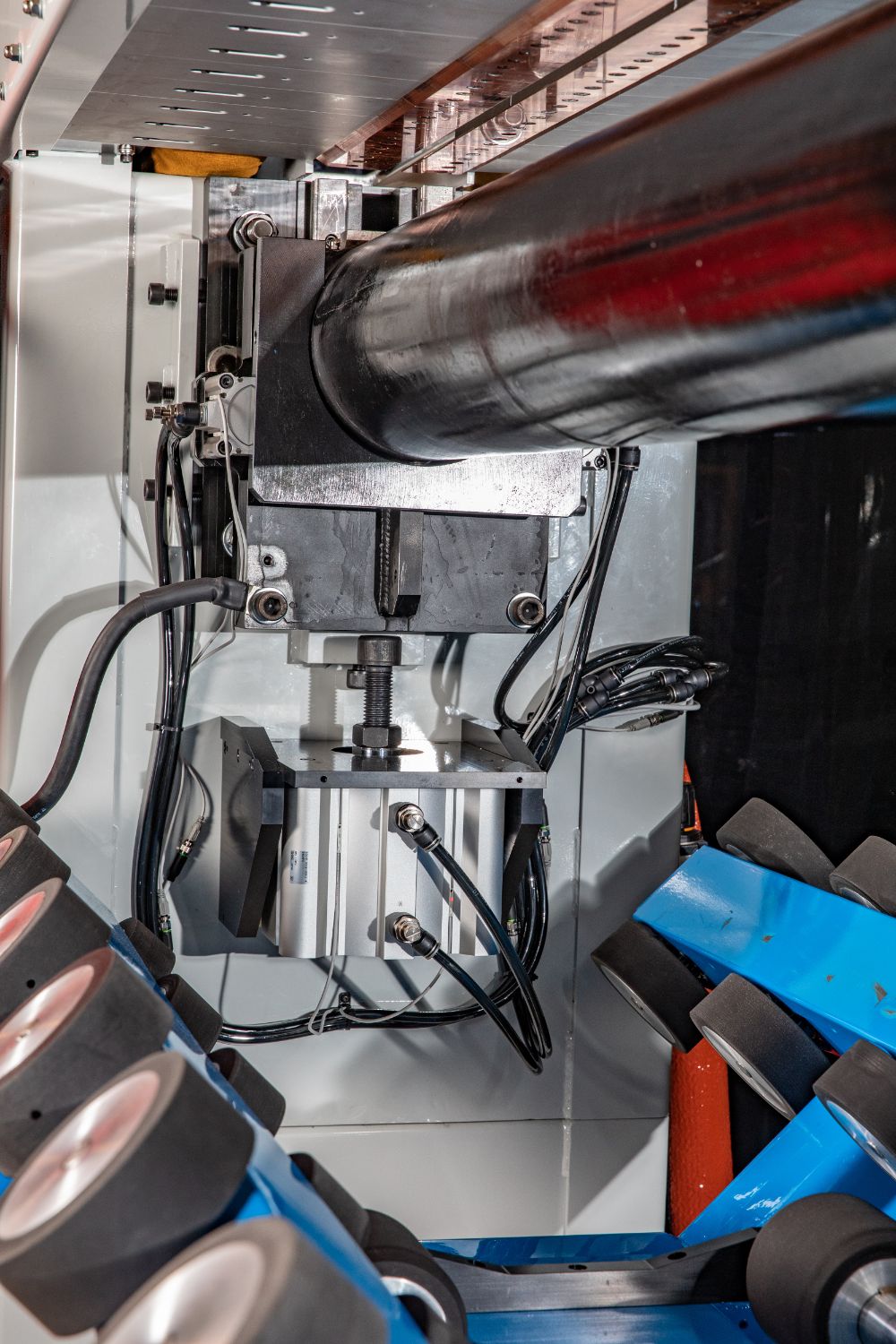

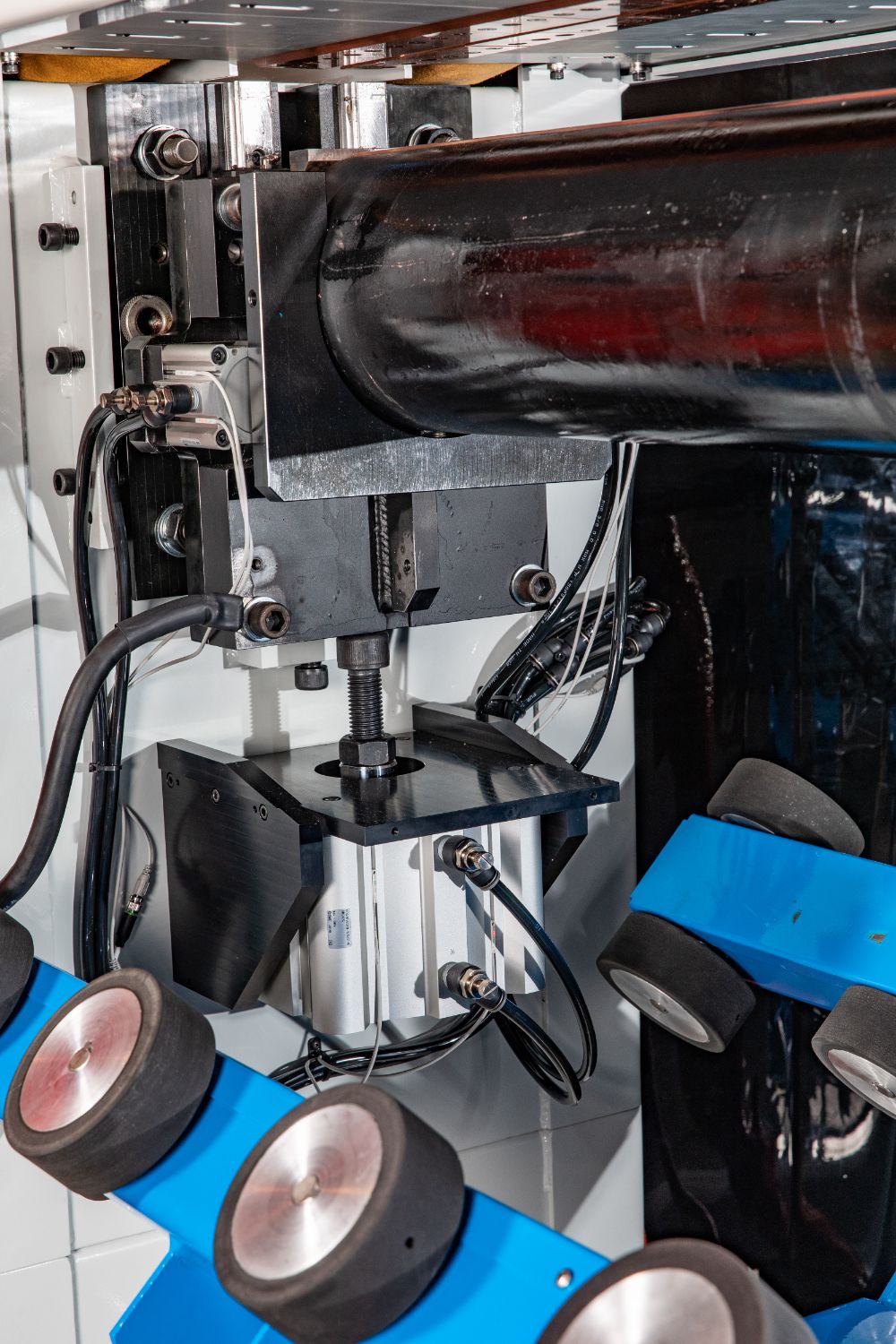

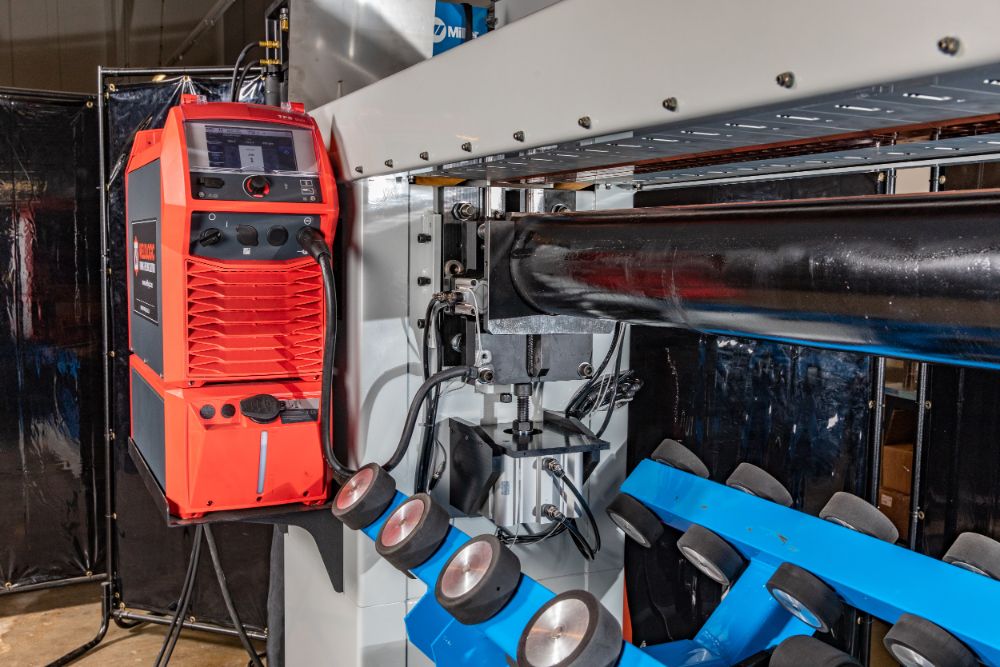

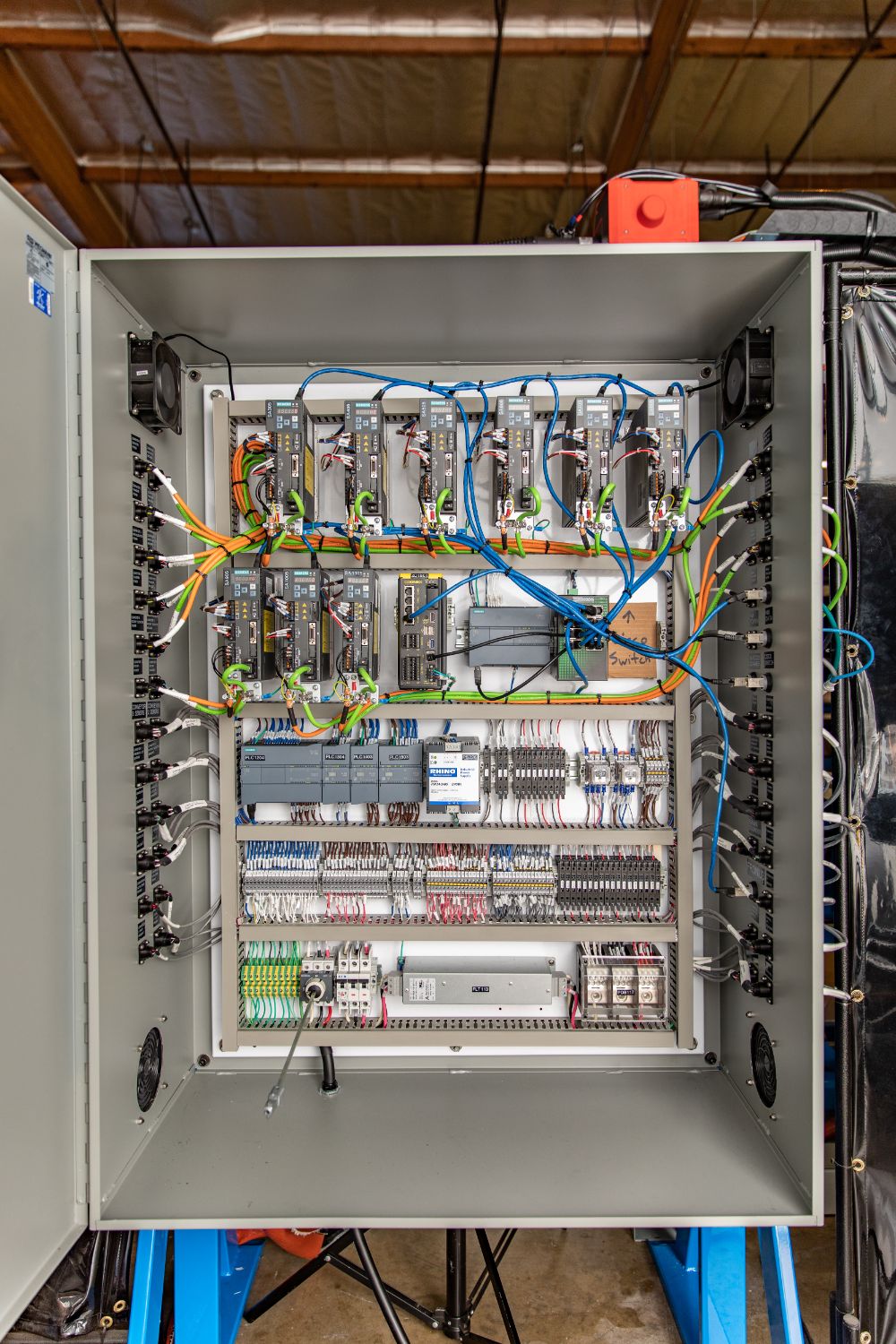

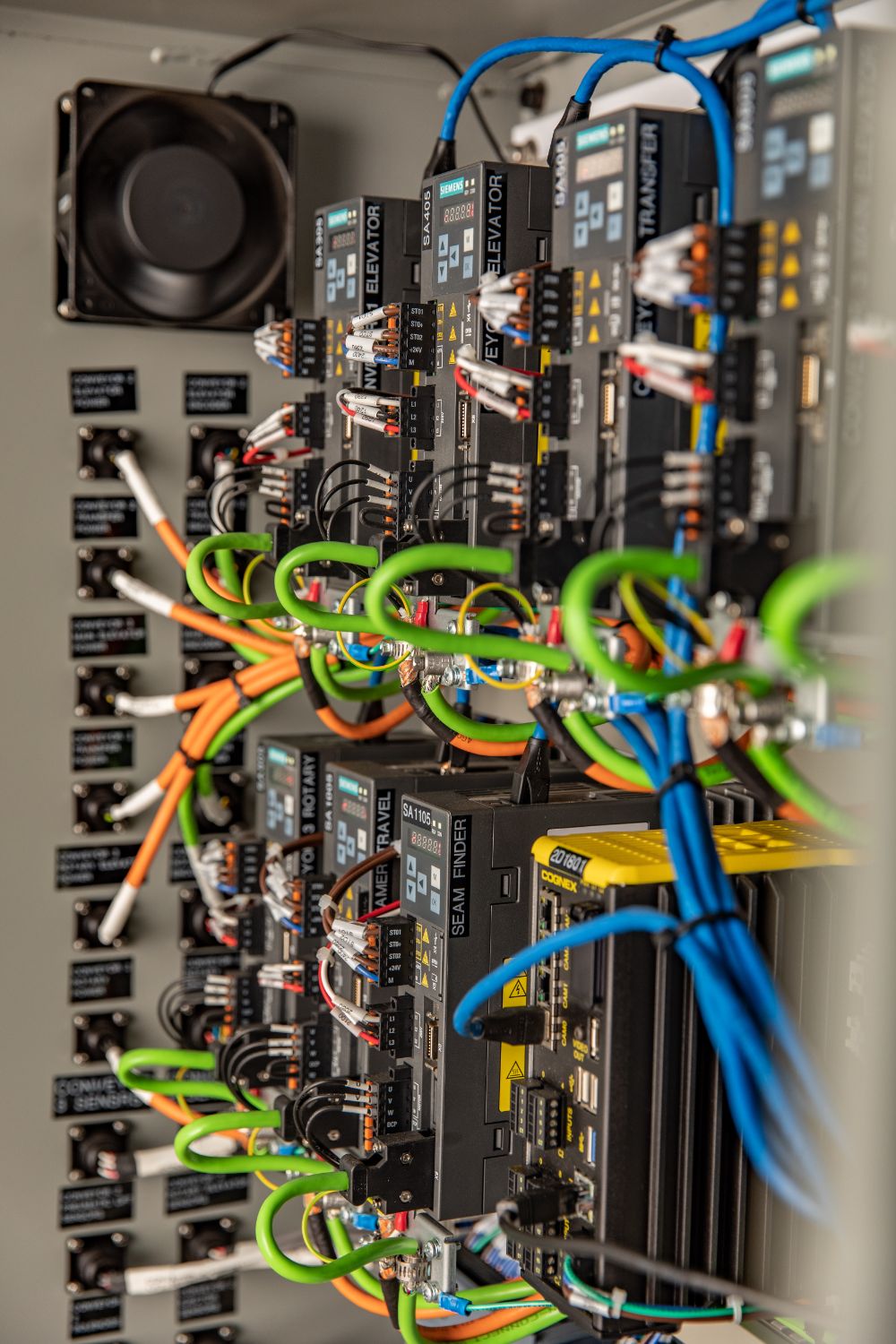

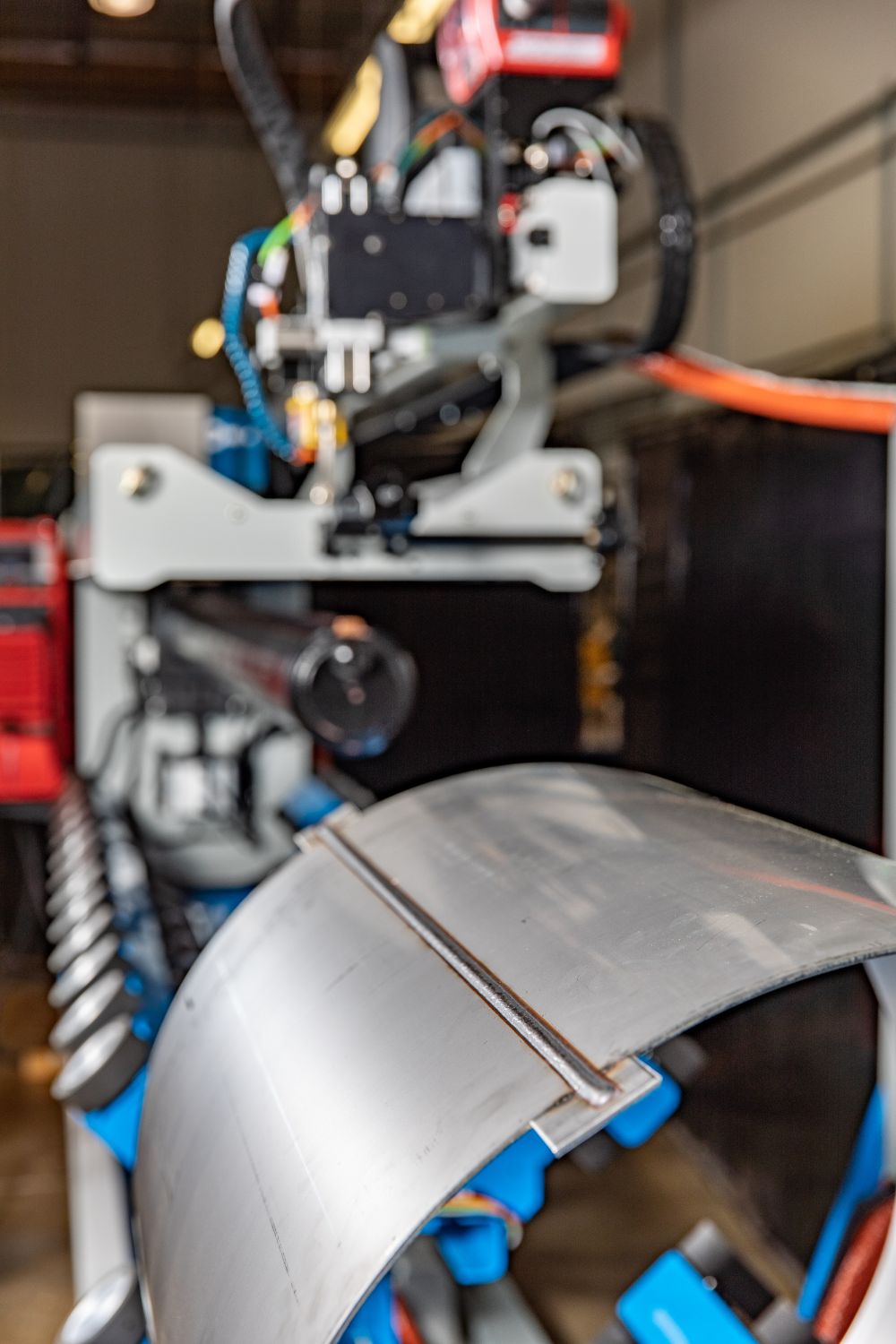

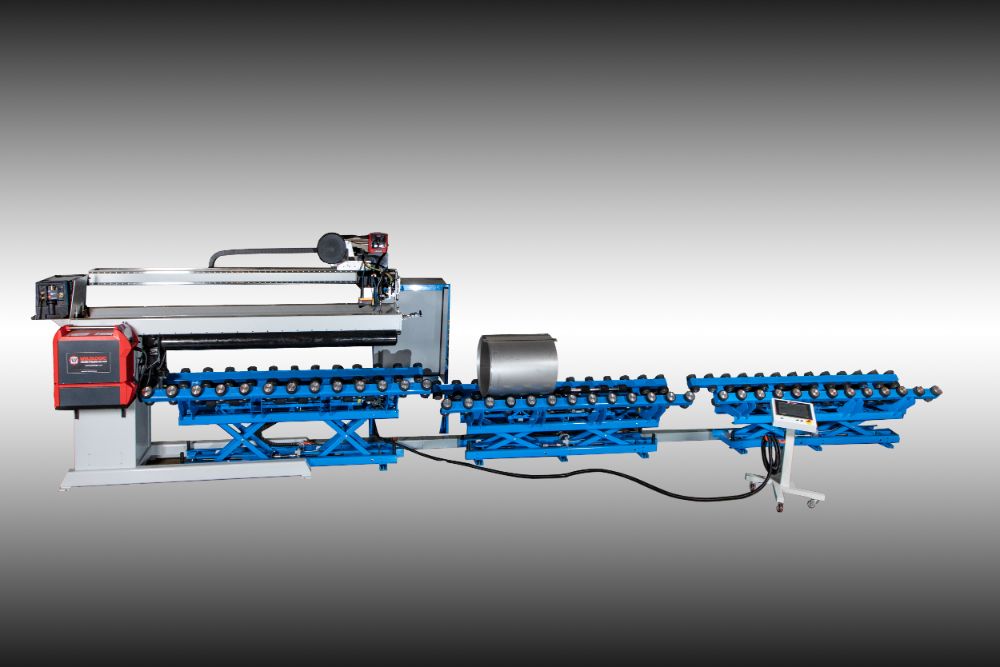

This would require a 9 axis machine to receive a wide range of tanks and auto- load, auto- position, auto- weld, auto-seam track, auto-eject & auto offload to circumferential welding station.

Solution:

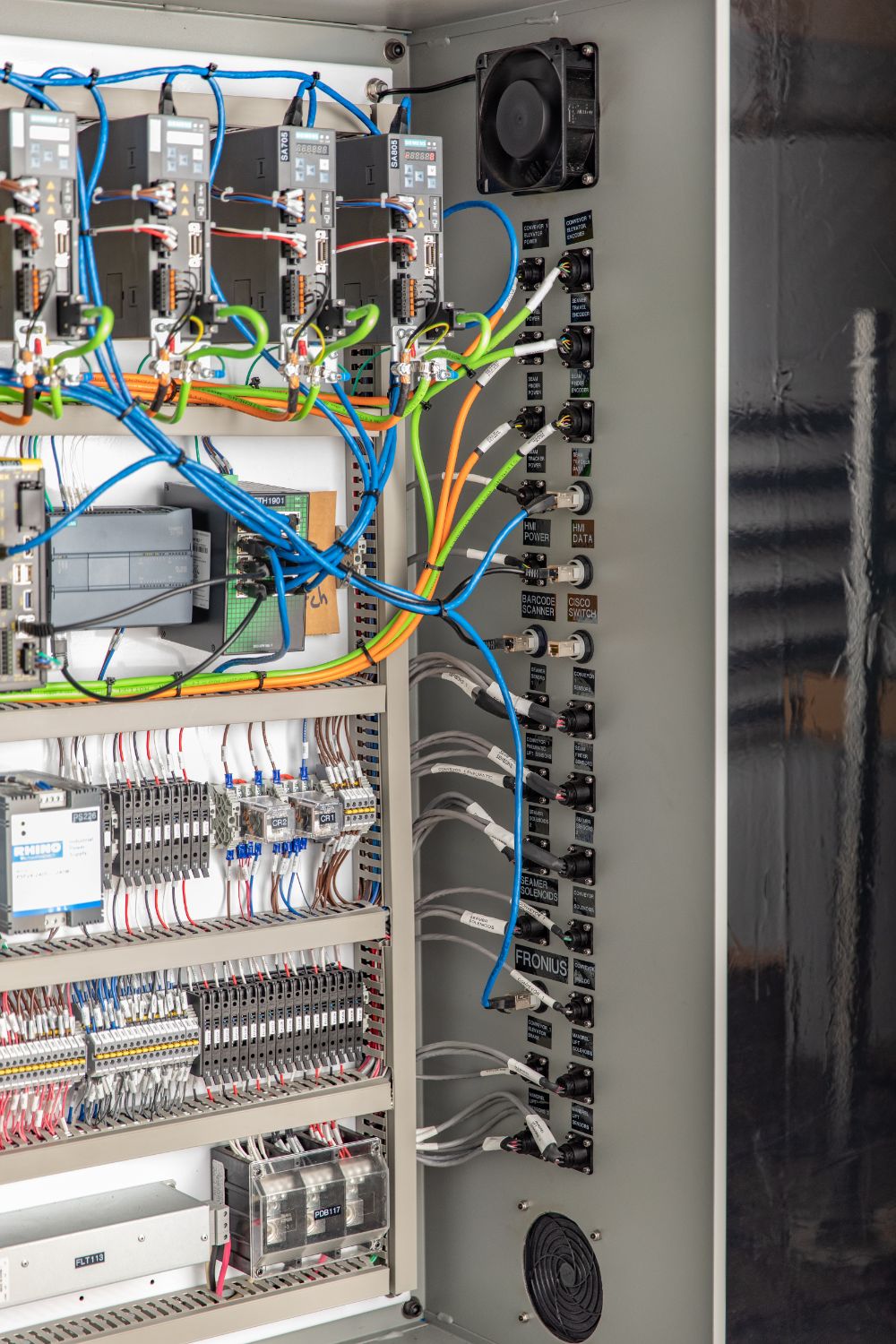

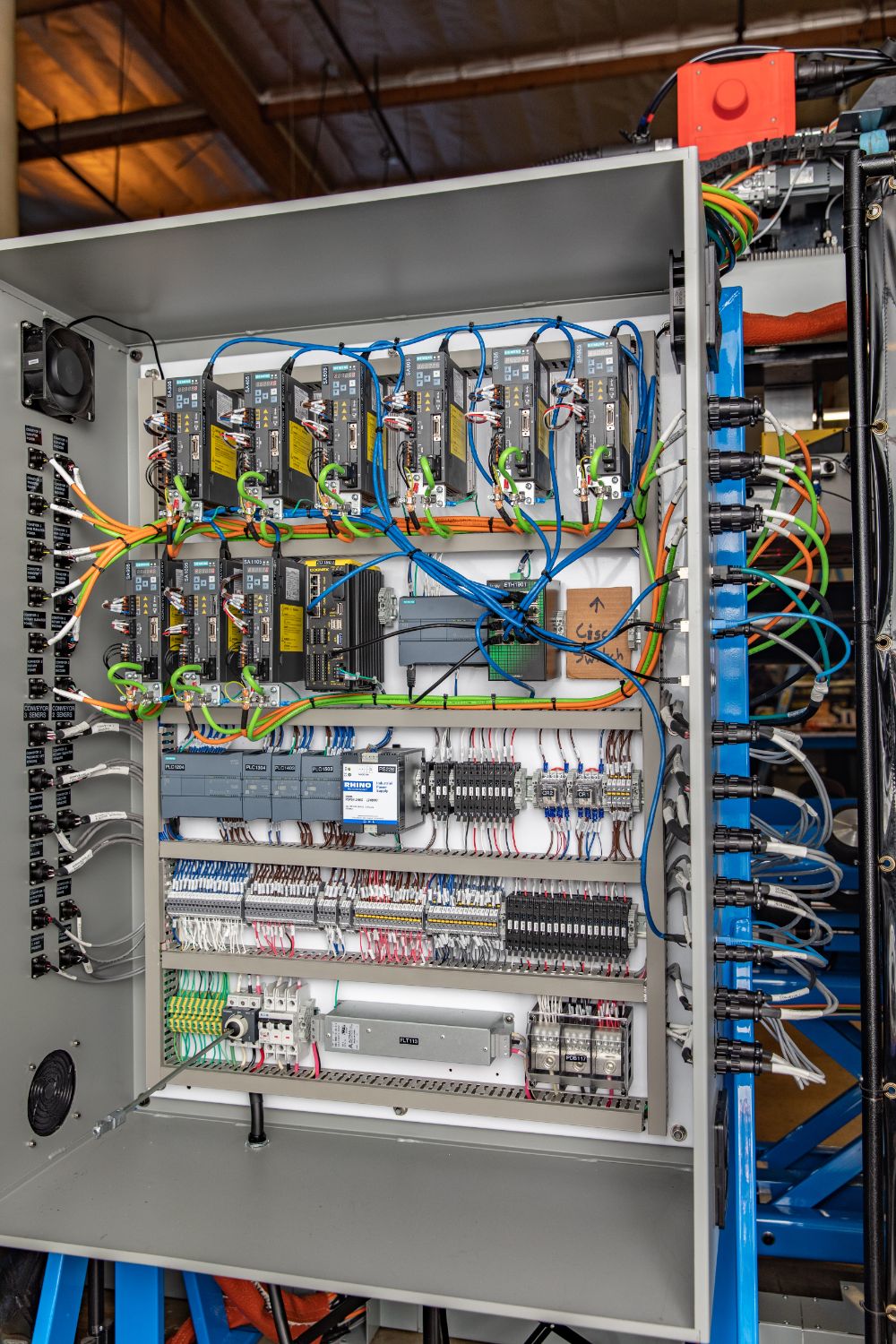

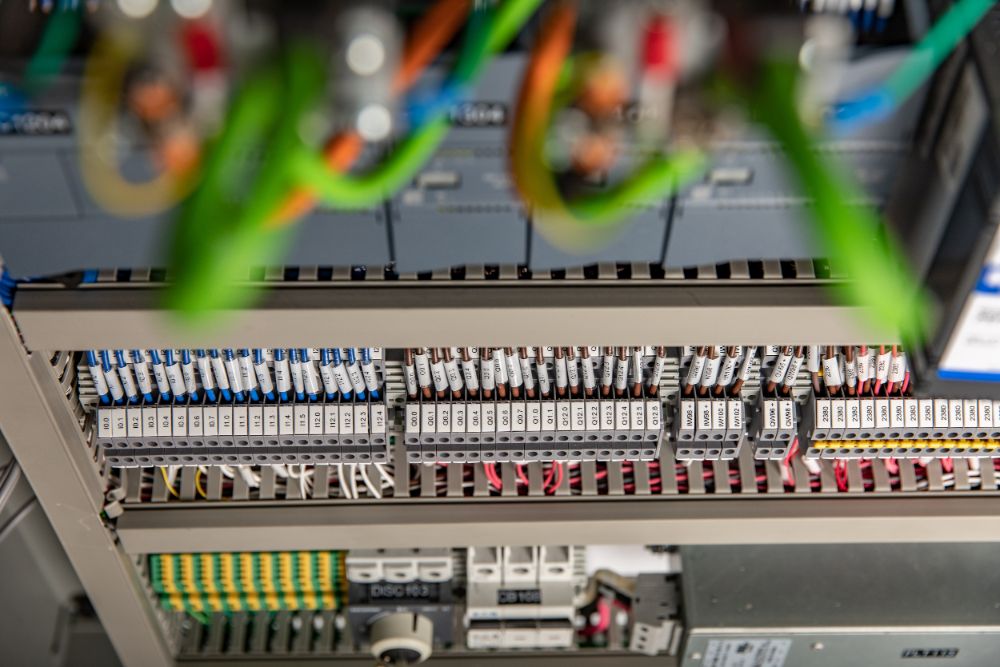

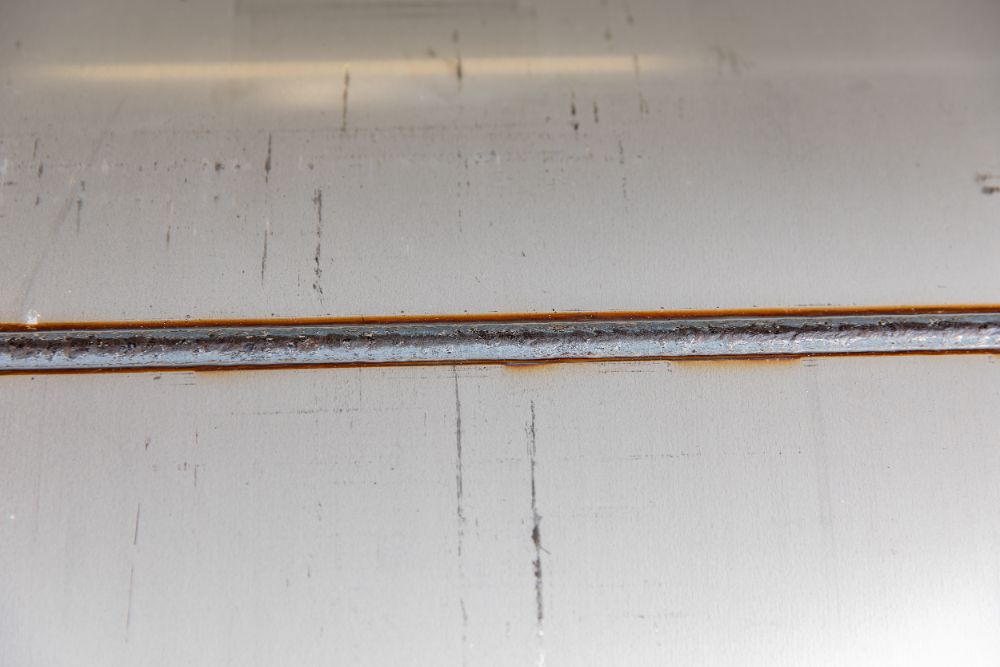

Weldlogic Engineering designed a Tank multi-axis transfer system to manage load and unload and build a controller that can be fed the correct tank part # to rapidly configure a specific program to seam weld and meet the X-ray clear welding requirements, operator free.

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A

Ask our experts about your unique challenge

Previous Product

PLS Seam Welder with Laser Seam Tracking