Introduction

CHALLENGE

Today in the U.S. there is a crippling shortage of skilled welders in the precision manufacturing sector. Over 450,000 jobs opening in the welding field, go unfilled due to a lack of trained and skilled welders. Weldlogic Engineering has been tasked by a custom motor manufacture to develop a system to significantly reduce or eliminate the high welding skill levels & costs required to make these very precise low distortion welds in today’s labor market.

SOLUTION

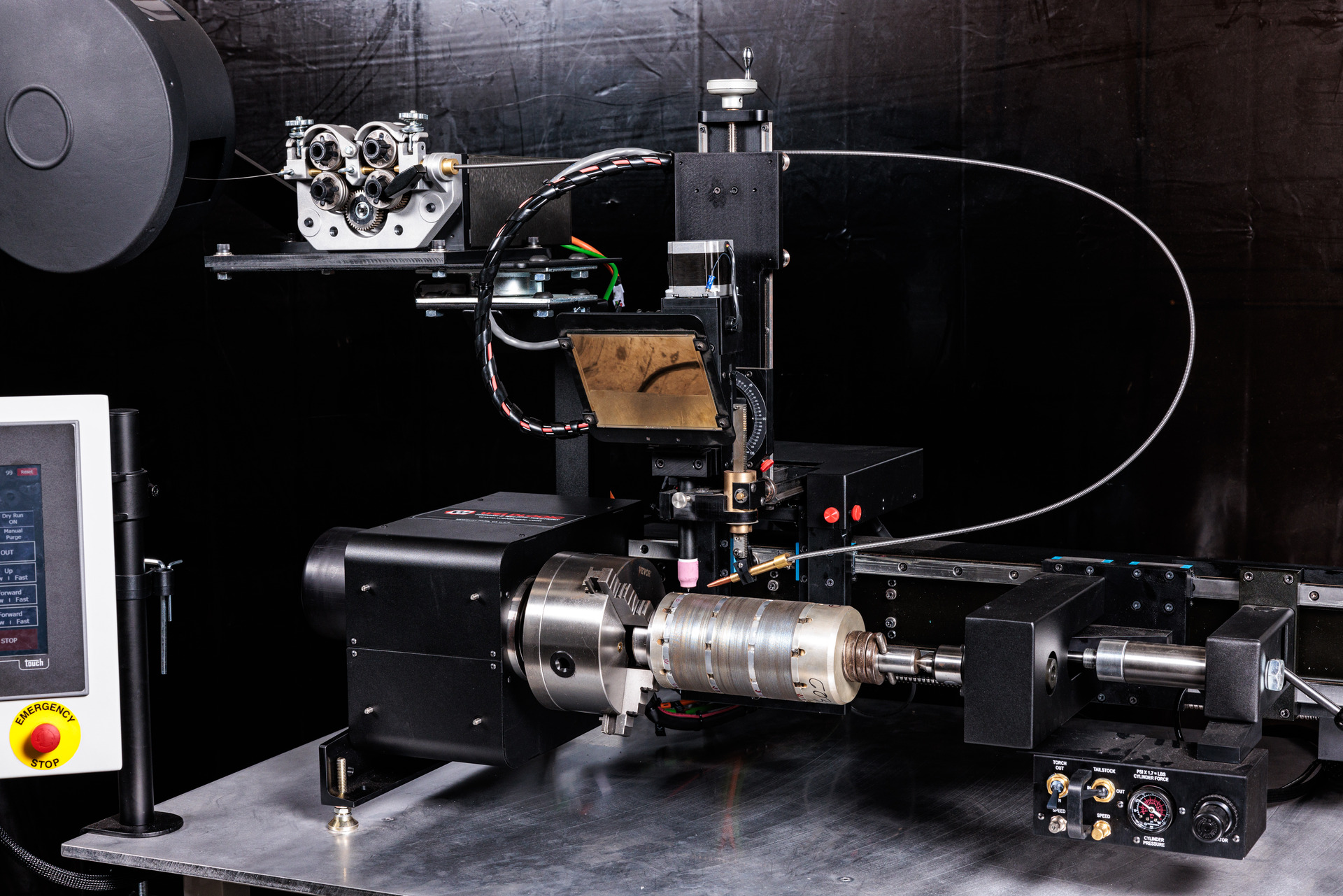

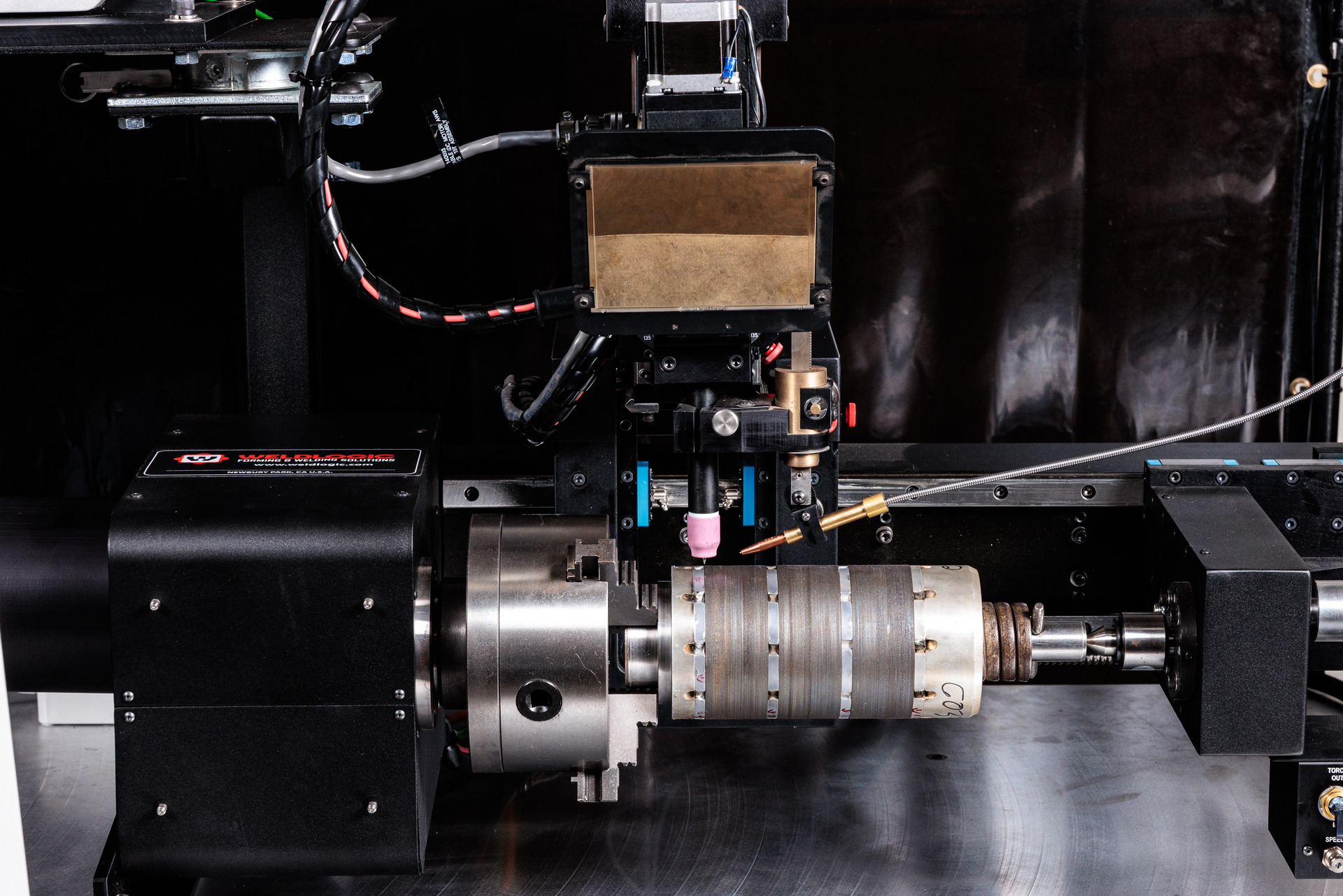

Design and fabricate a user friendly 2 axis weld cell to enable a wide range of motor diameters and lengths to be seam welded reliably using a system that saves and retrieves all the program to enable low heat input / low distortion automatic welds.

The system consists of the following Weldlogic standard products:

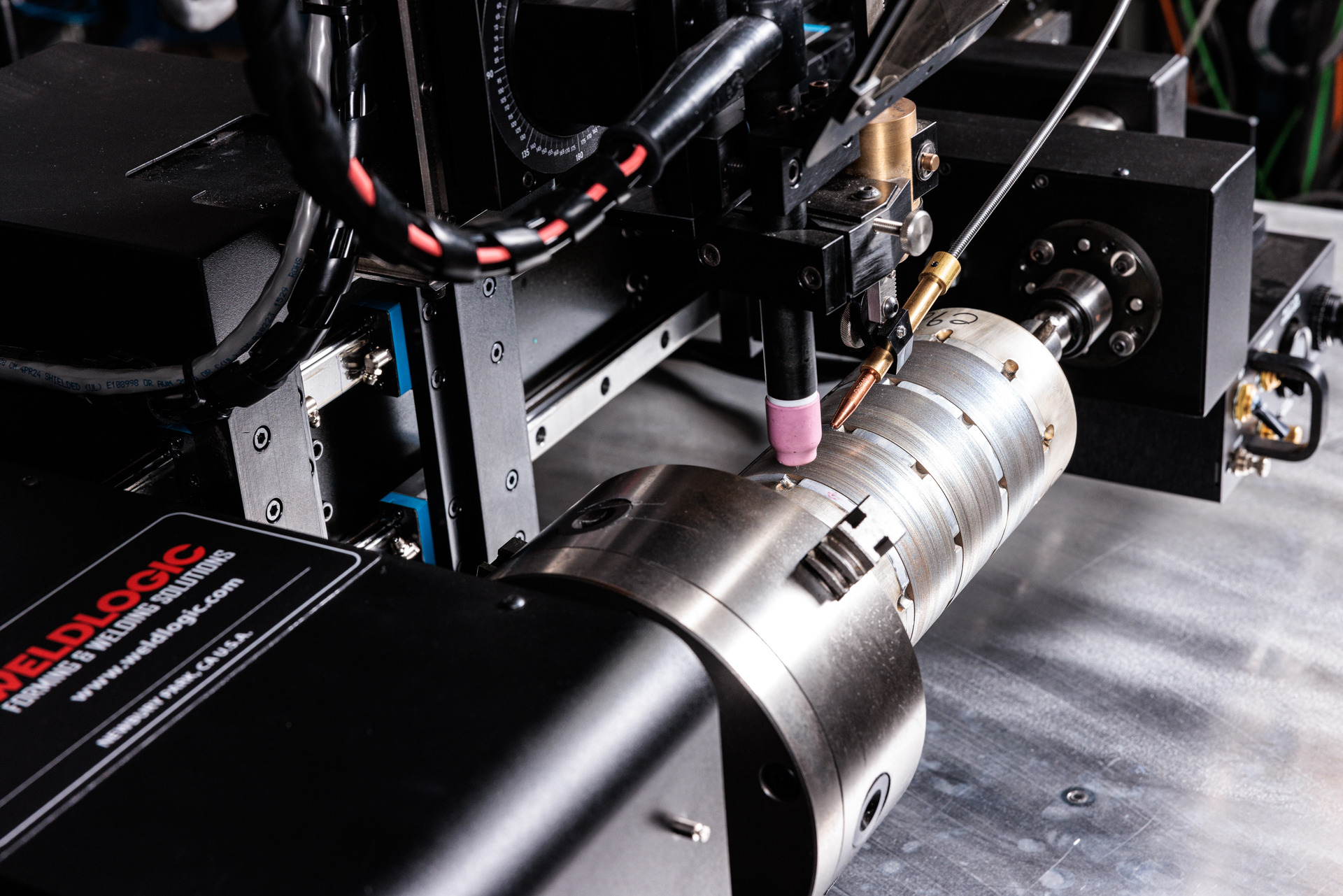

- PWL-15-21 Precision Welding Lathe AC Servo driven in 2 axes

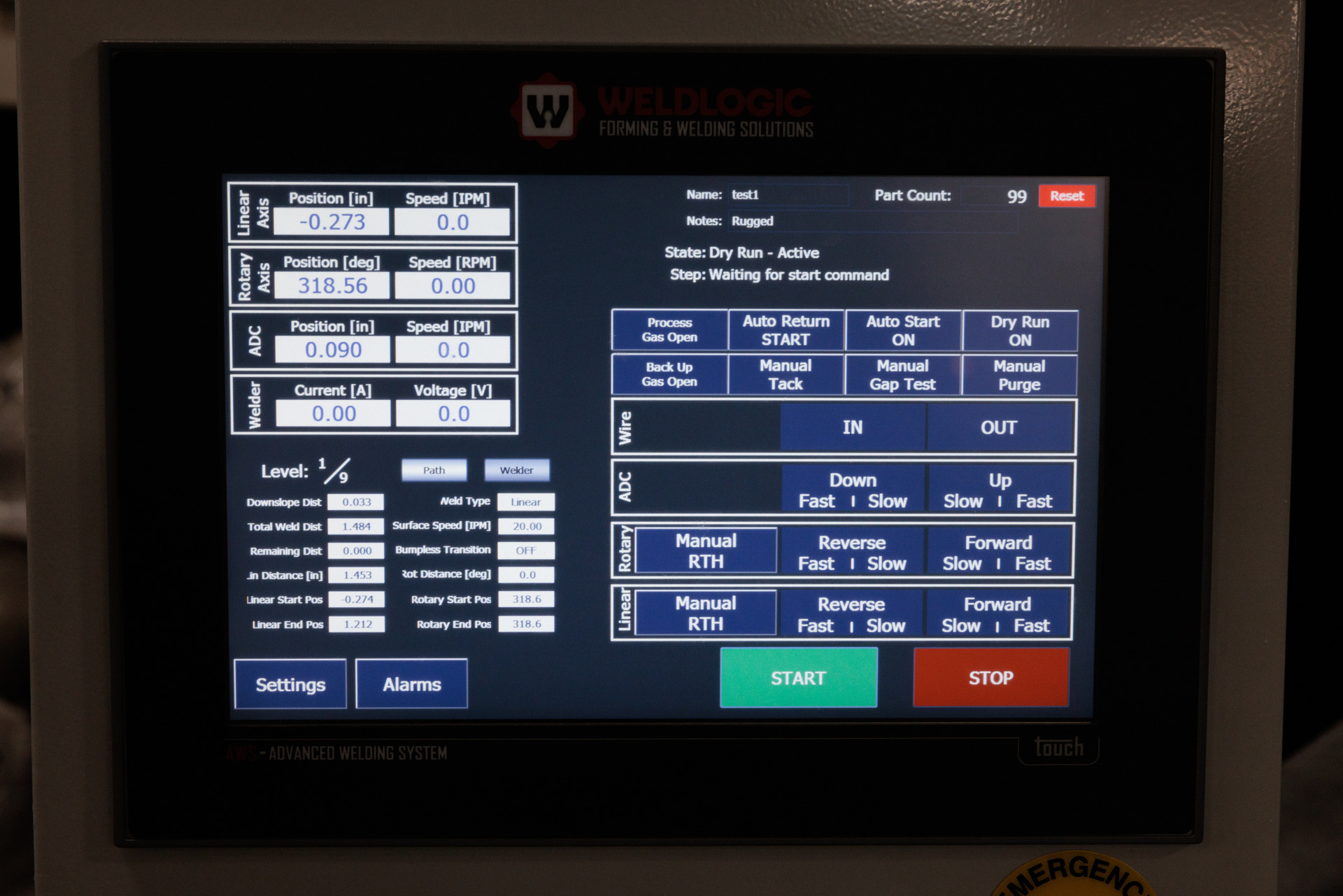

- AWS-210 Advanced Welding System, weld controller with memory

- Arc Distance Controller

- 12″ HMI to program and operate system

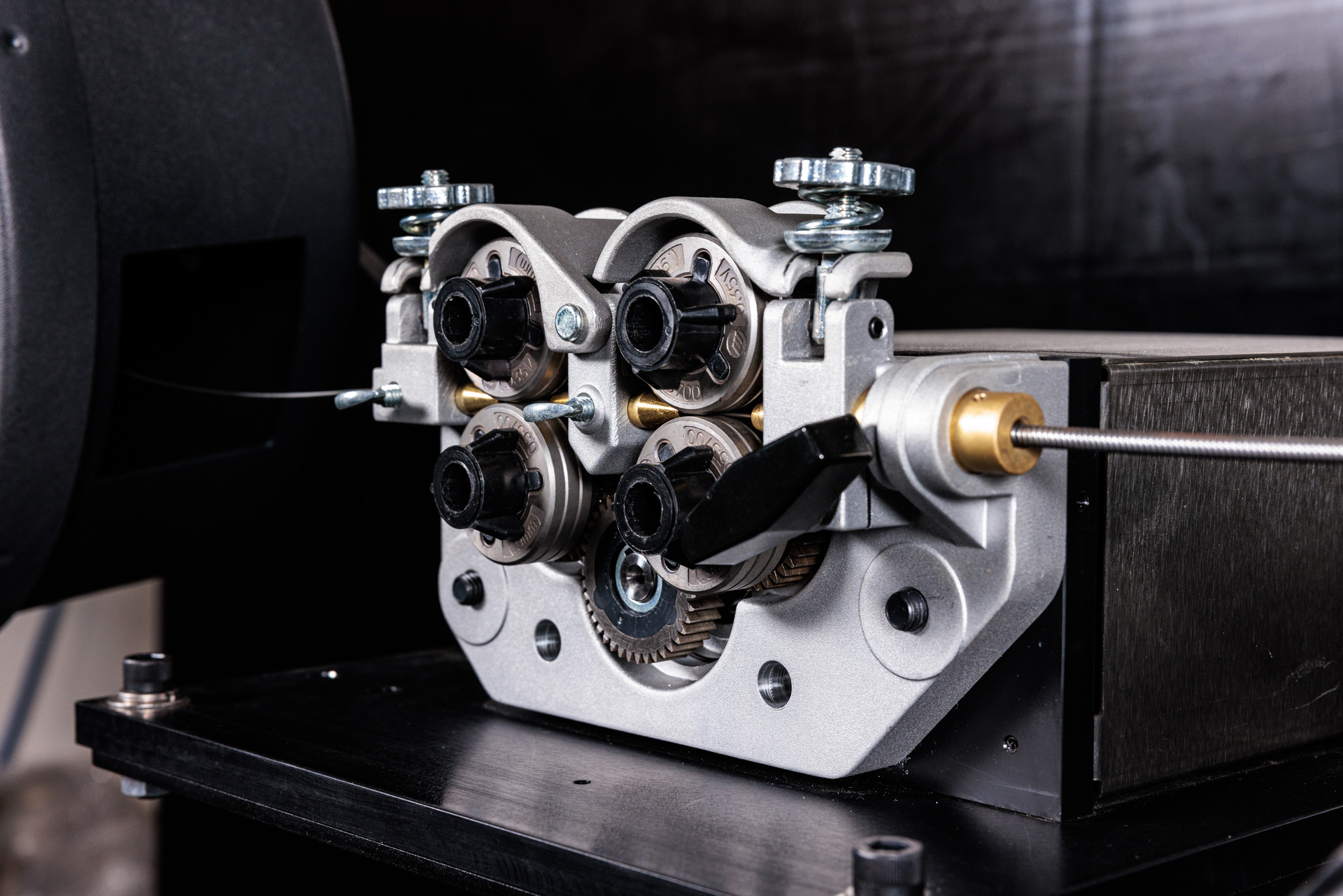

- Cold Wire Feeder

- Workstation Table with flip up arc shield

- Weld Process developed with training

- Weld Support- life time of equipment

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A