Introduction

Challenge

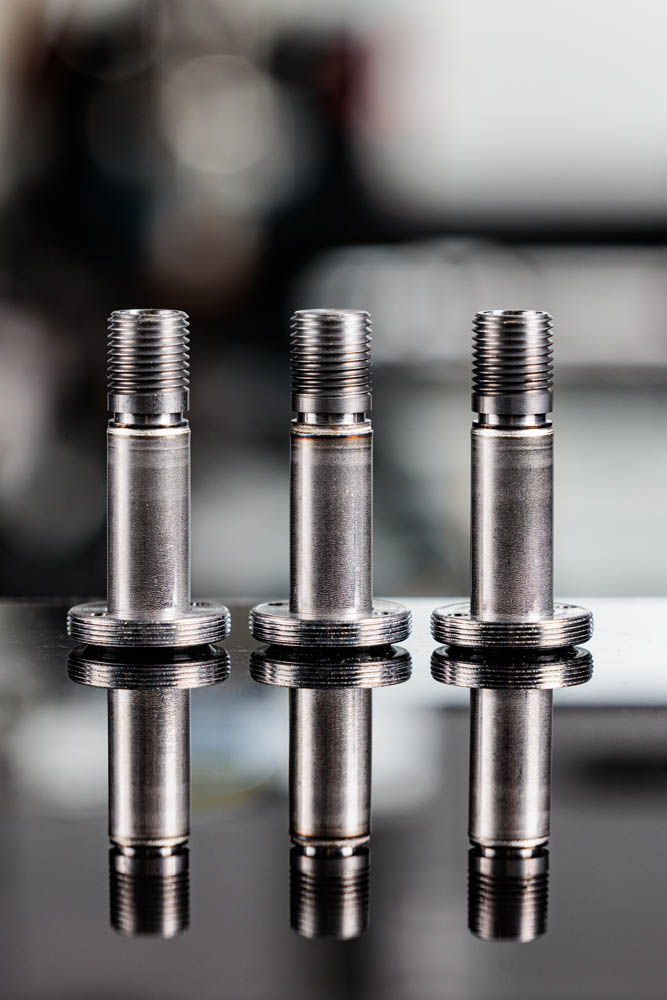

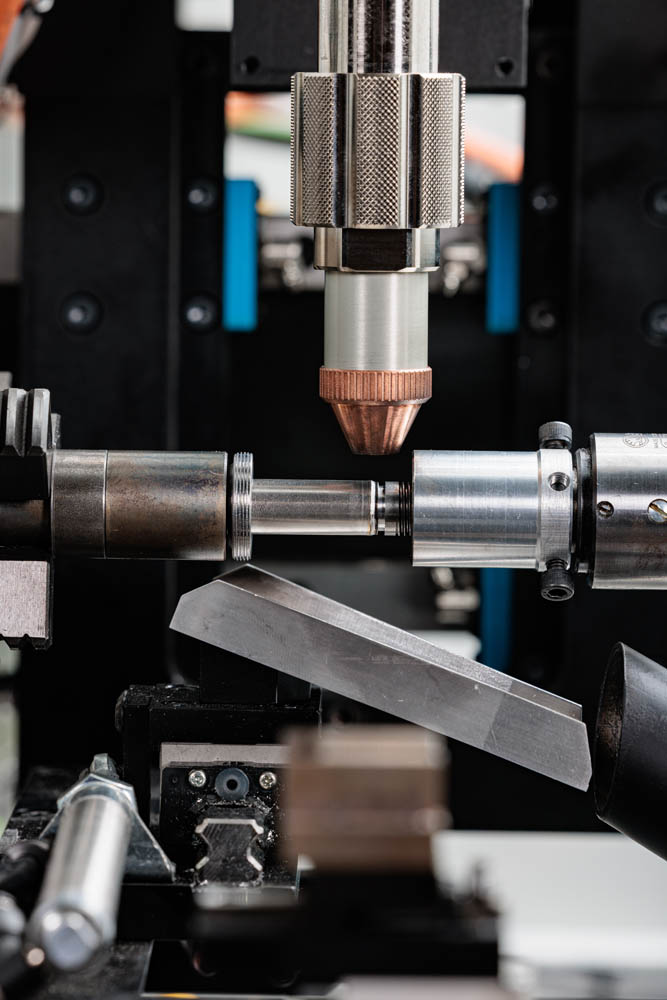

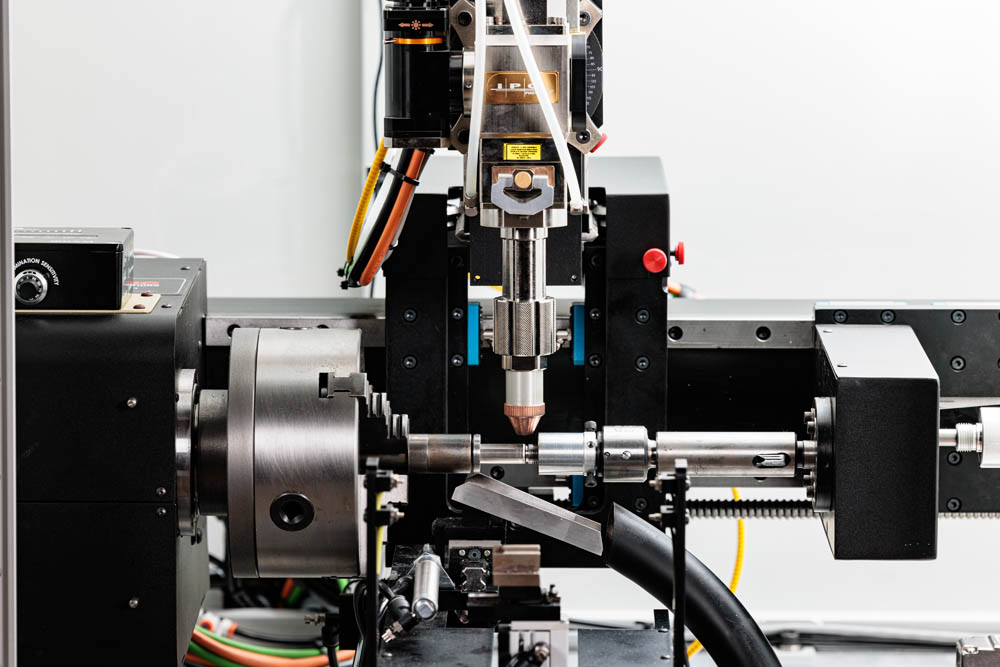

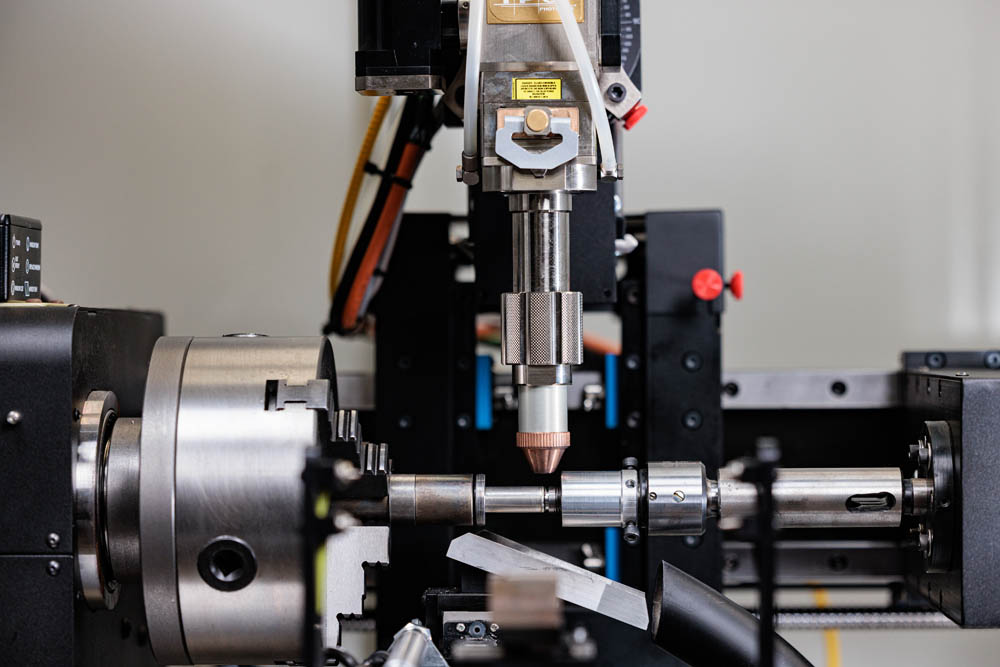

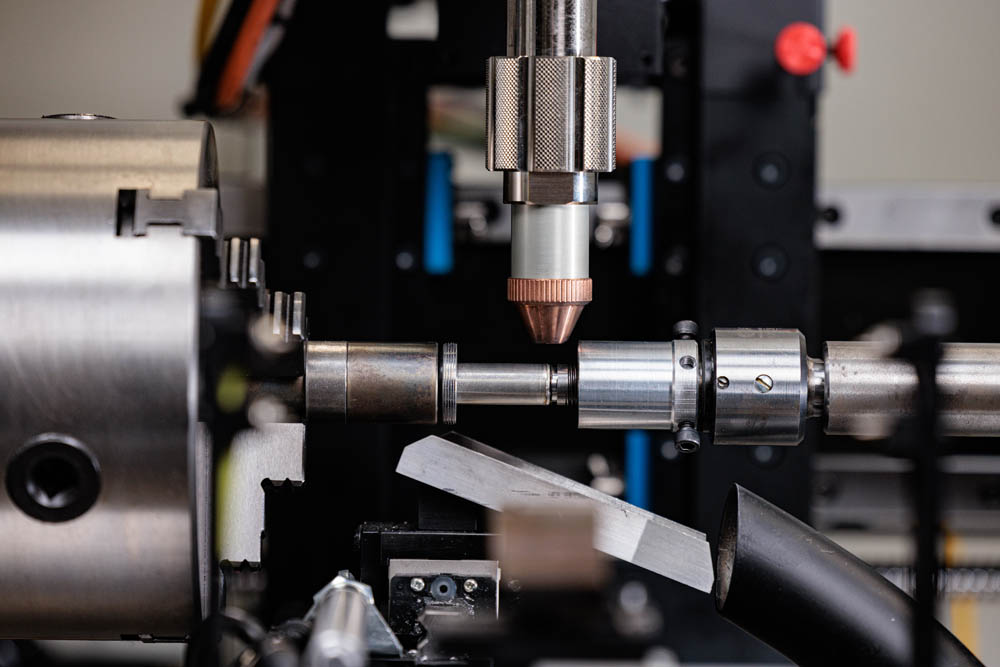

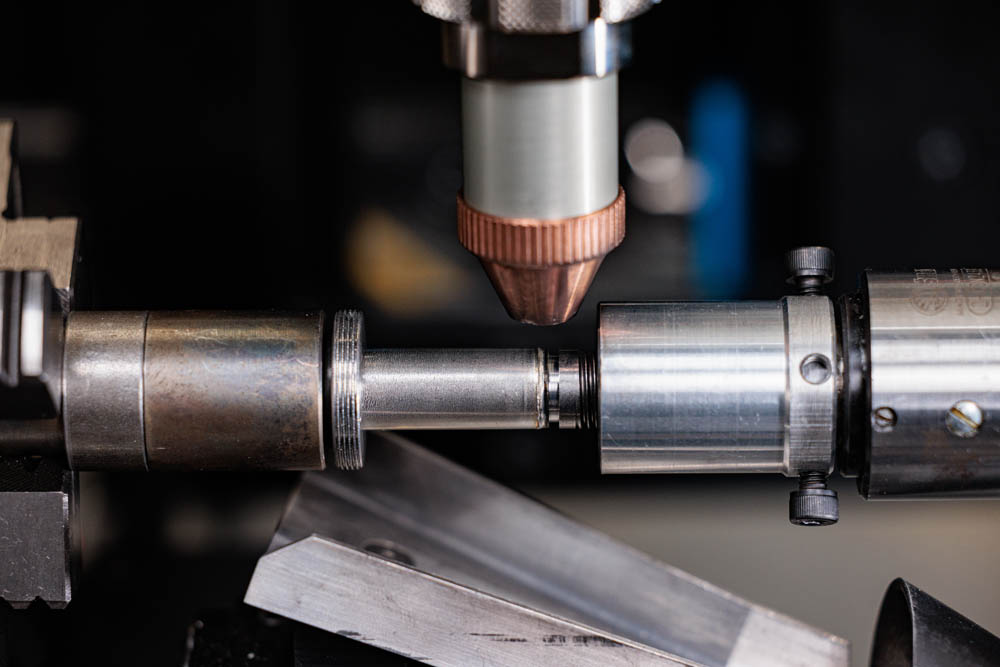

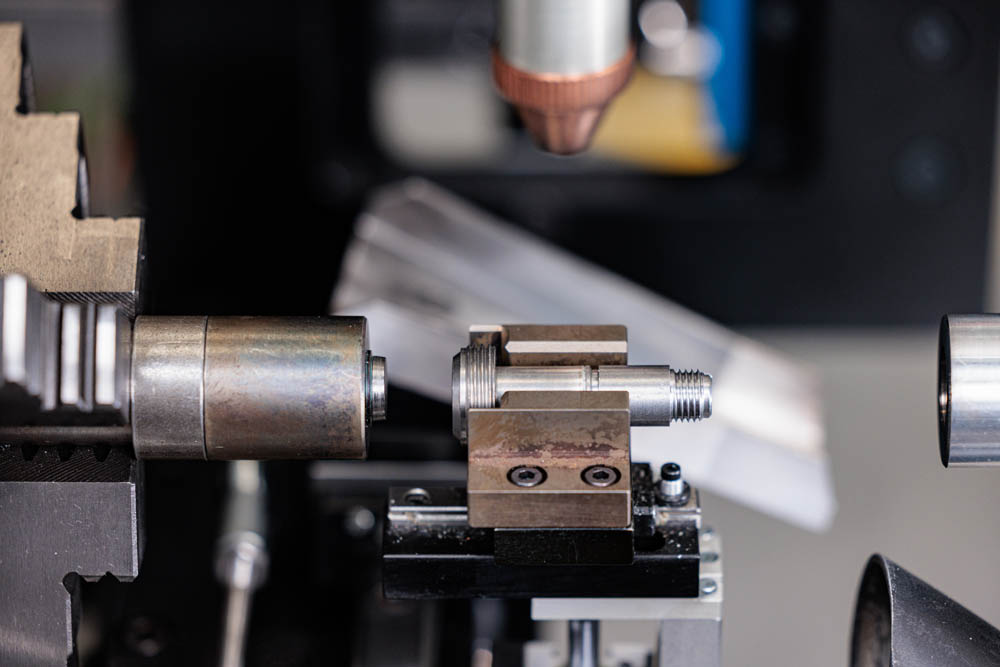

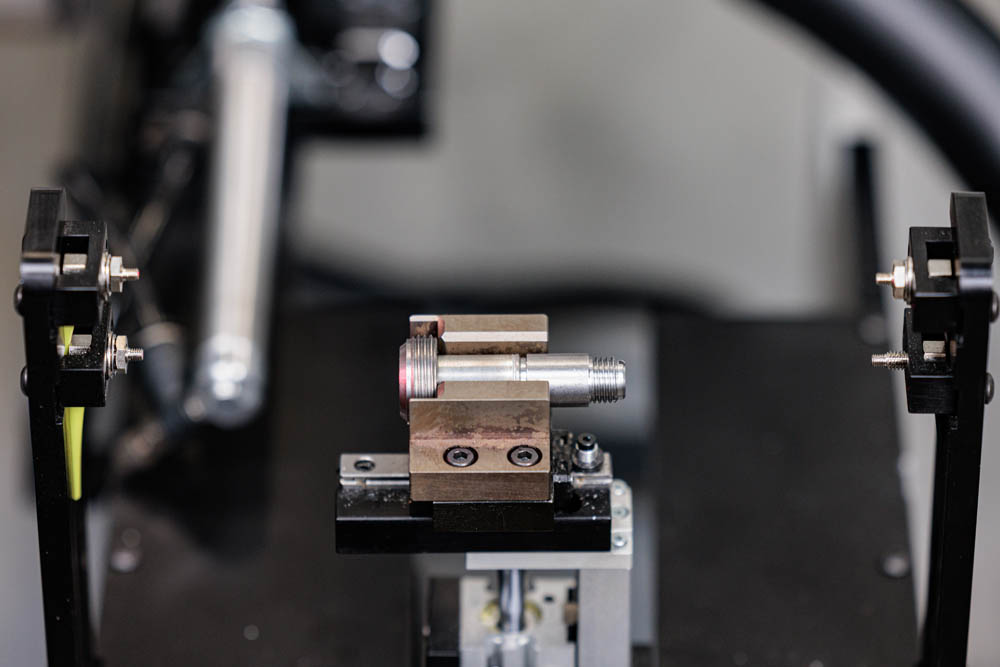

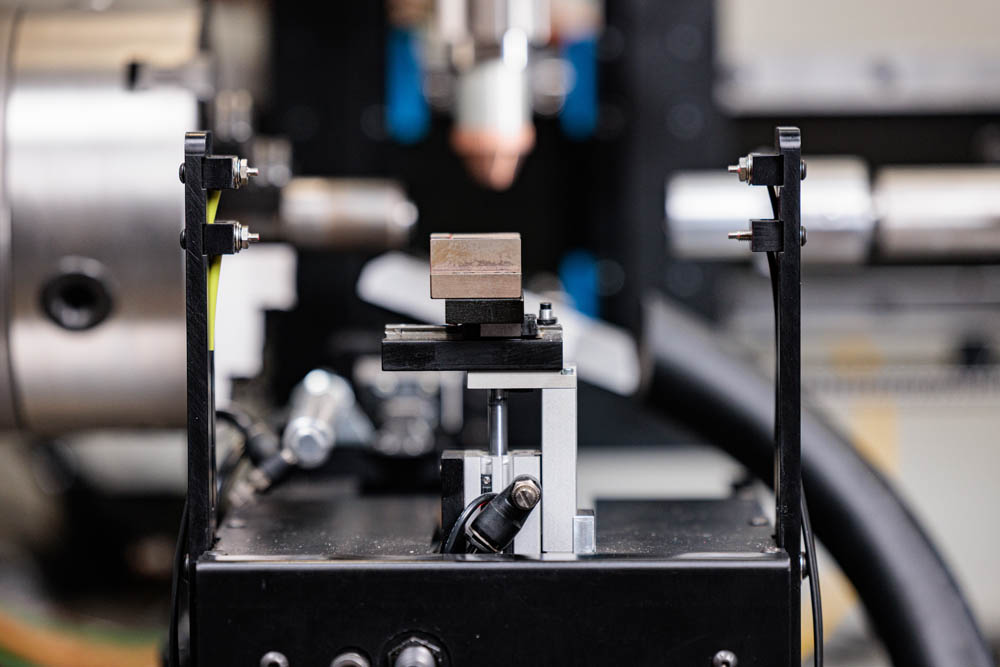

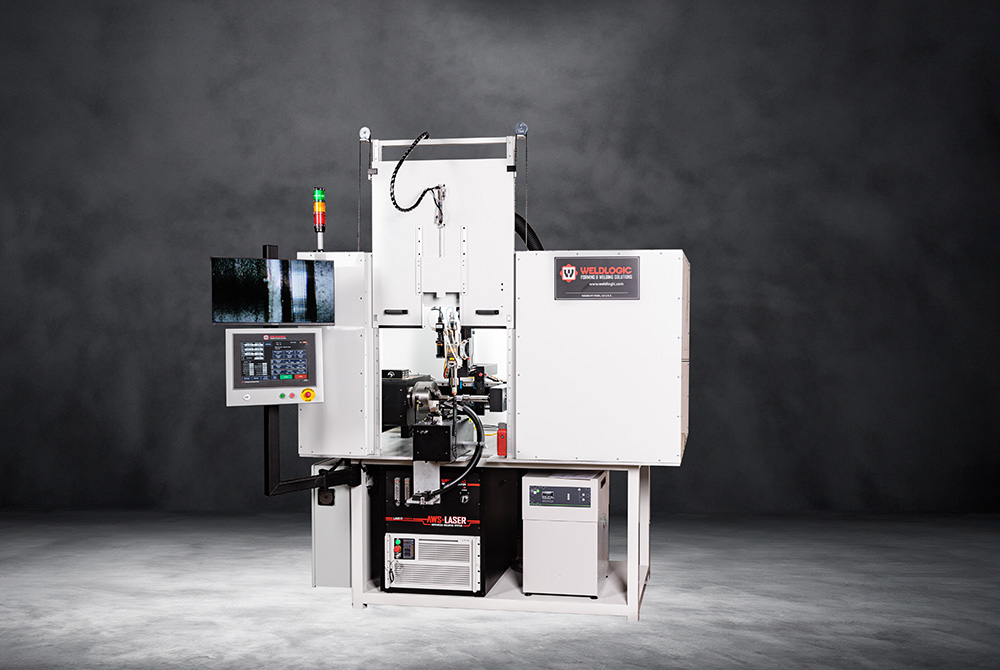

A Customer approached Weldlogic to help them fully automate a line that included a critical weld process that was previously GTAW/TIG welded. We were tasked to design and build a custom laser welding cell that would enable a Solenoid Manufacture to operate an entire assembly and weld line operator free. The Laser Weld Cell would need to receive the solenoid assembly from a high-speed pick and place, auto-load into our tooling & part shuttle and weld the solenoid and eject in the correct orientation to enable the pick and place to retrieve it and place onto the assembly line in the correct orientation.

Solution

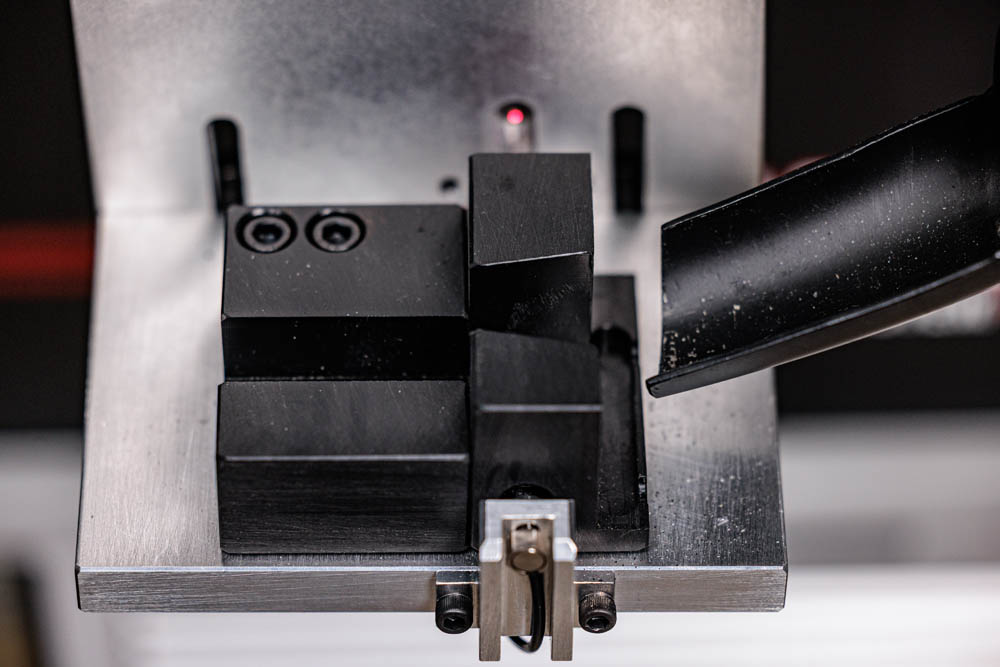

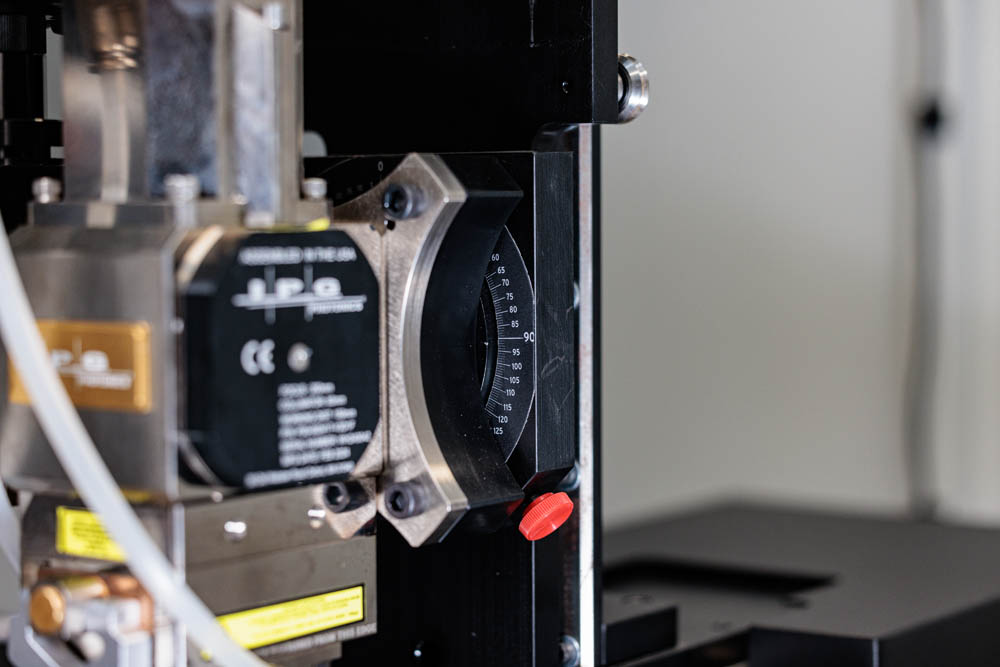

Weldlogic Mechanical, Electrical & Weld Engineering Departments met with the customer to assess how many part variations, weld requirements, productivity P.P.H., Assembly In-Feed and Out-Feed were needed. The result of those detailed meetings was an Automated High Production Laser Cell that operates entirely thru multiple I/O and sensors to validate part position and system status.

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A