Introduction

CHALLENGE

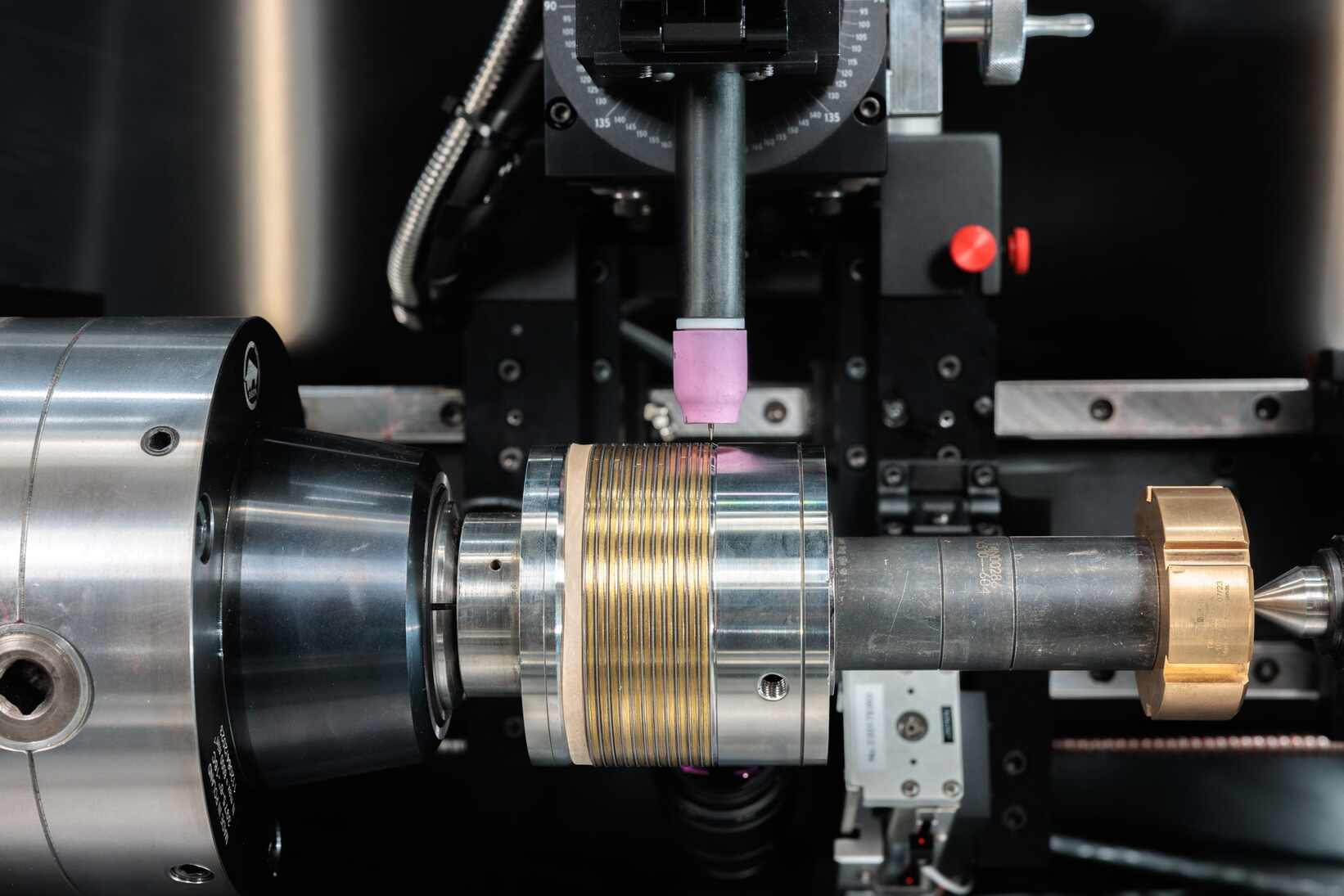

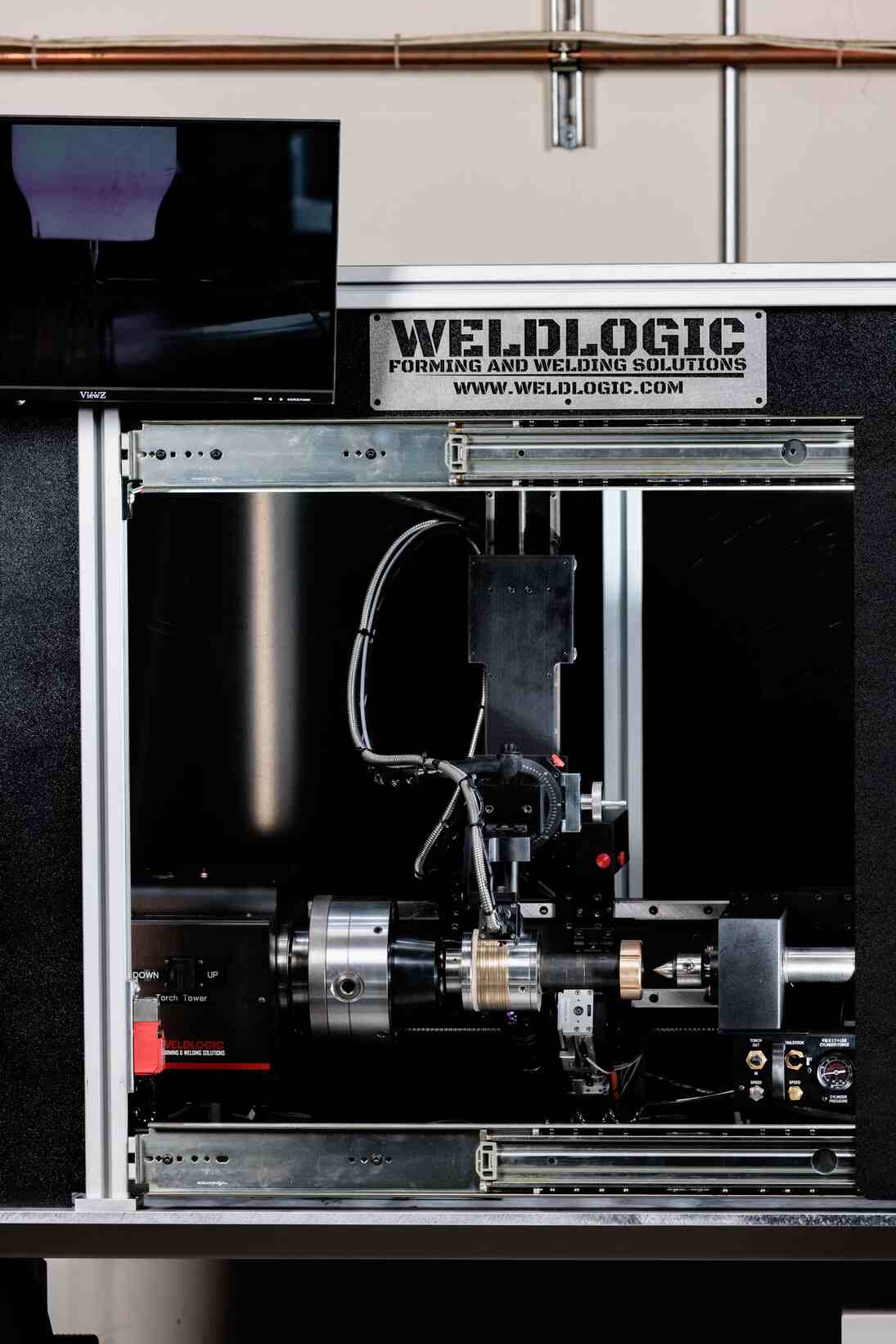

Today in the U.S. there is a crippling shortage of skilled welders in the precision manufacturing sector. Over 450,000 jobs opening in the welding field, go unfilled due to a lack of trained and skilled welders. Weldlogic Engineering has been tasked by several bellows companies to design AUTOMATIC / O.D. & I.D. bellows weld cells to significantly reduce or eliminate the high welding skill levels & costs required to make these very precise micro welds in today’s labor market.

SOLUTION

Design and refine hardware, software & vision systems to enable an operator to select the proper

program, load a tooled assembly of bellows and press one button to perform the following:

- Seek the First bellow and align weld directly over seam center.

- Set height positioning weld at perfect z axis position.

- Load weld schedule (weld energy, rotation, purge program from saved recipe.

- Weld entire bellows without an operator.

- Remove and replace bellows assembly and load next one- repeat.

OPTIONS:

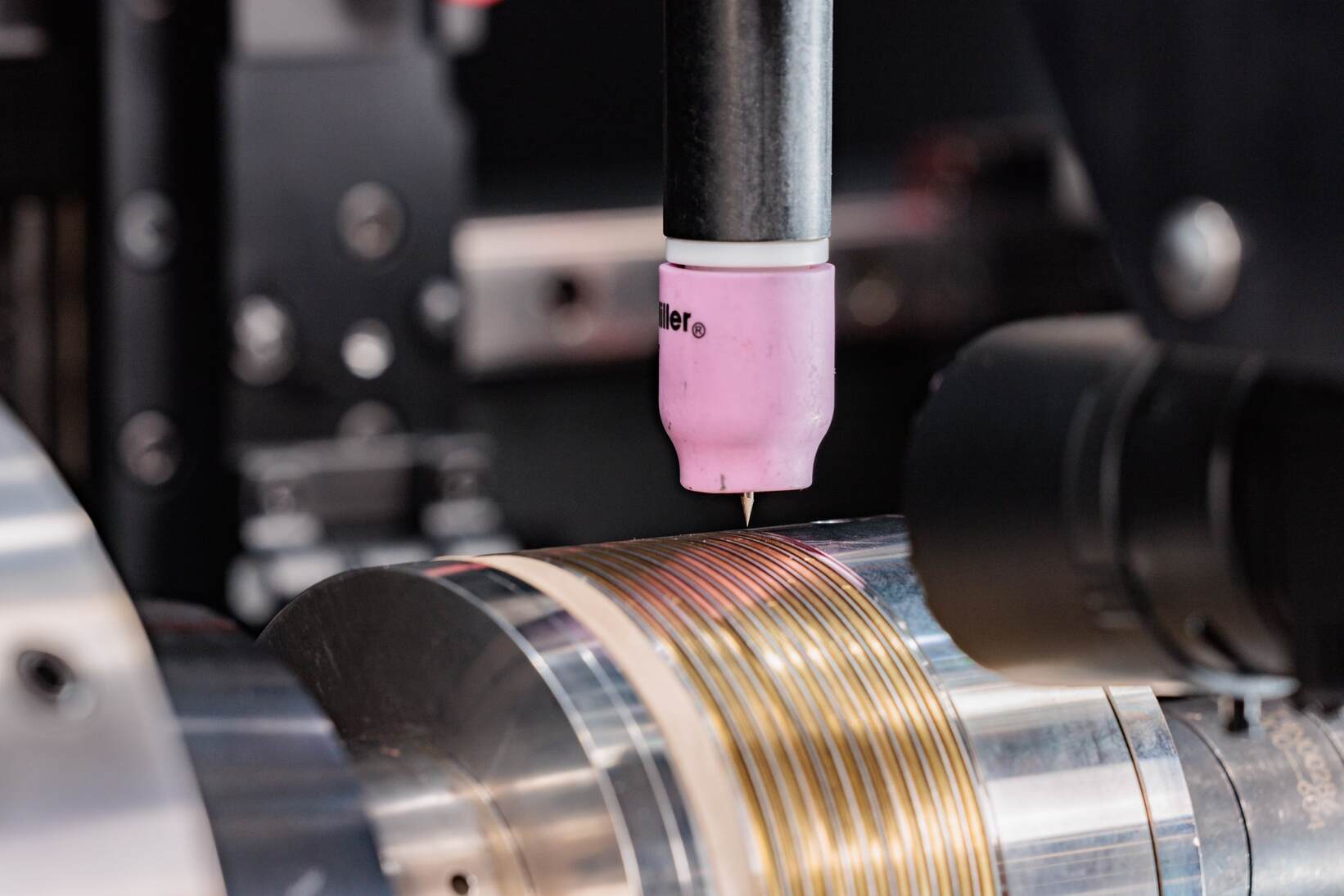

- Micro-Tig, Plasma or Laser

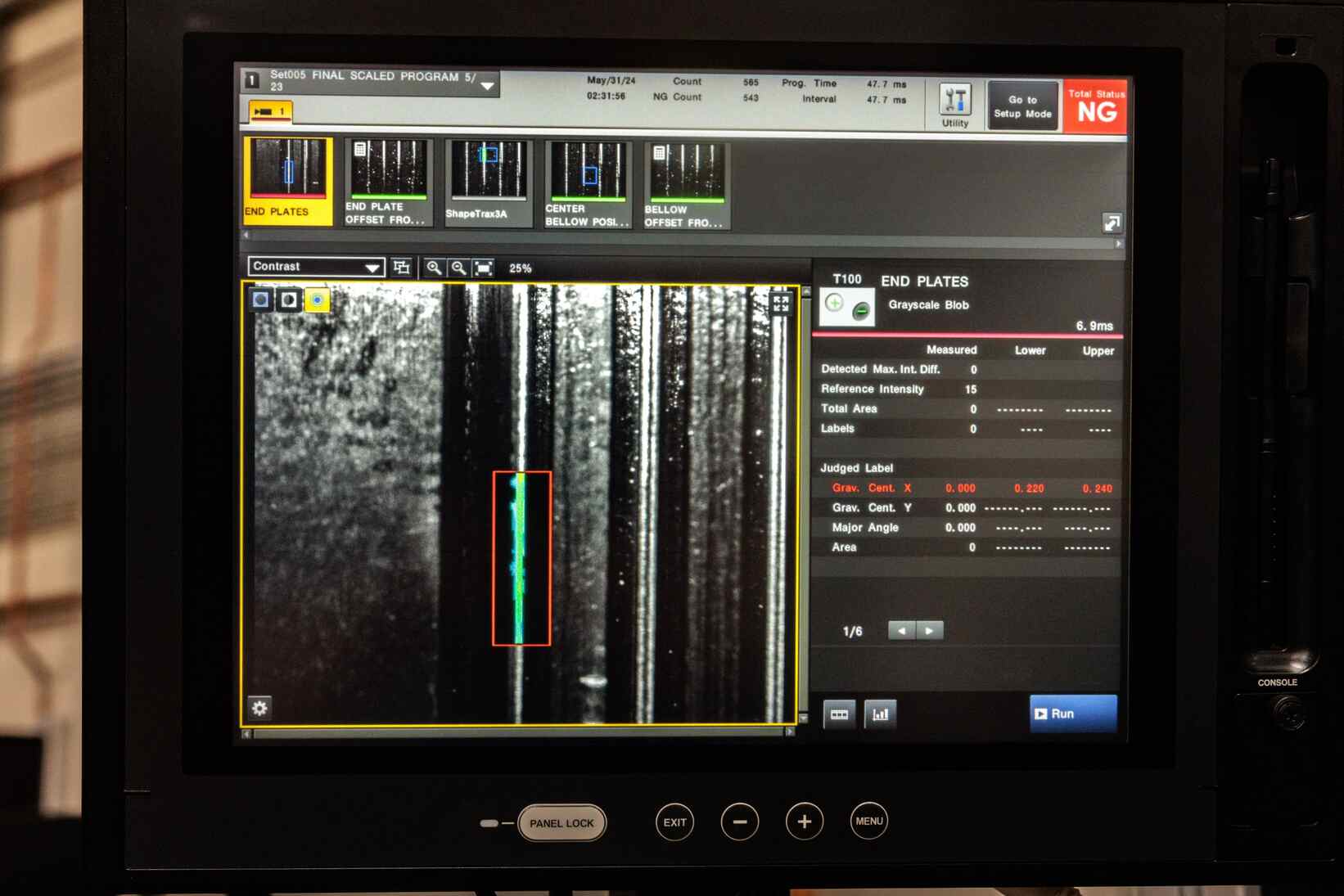

- Post weld Measurement/Inspection of bellows weld for Q.C. acceptance records

- Multiple programming with end plate welds

- Custom tailored features not noted

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A

Ask our experts about your unique challenge

Previous Product

CNC Laser Welding Lathe