Introduction

CHALLENGE

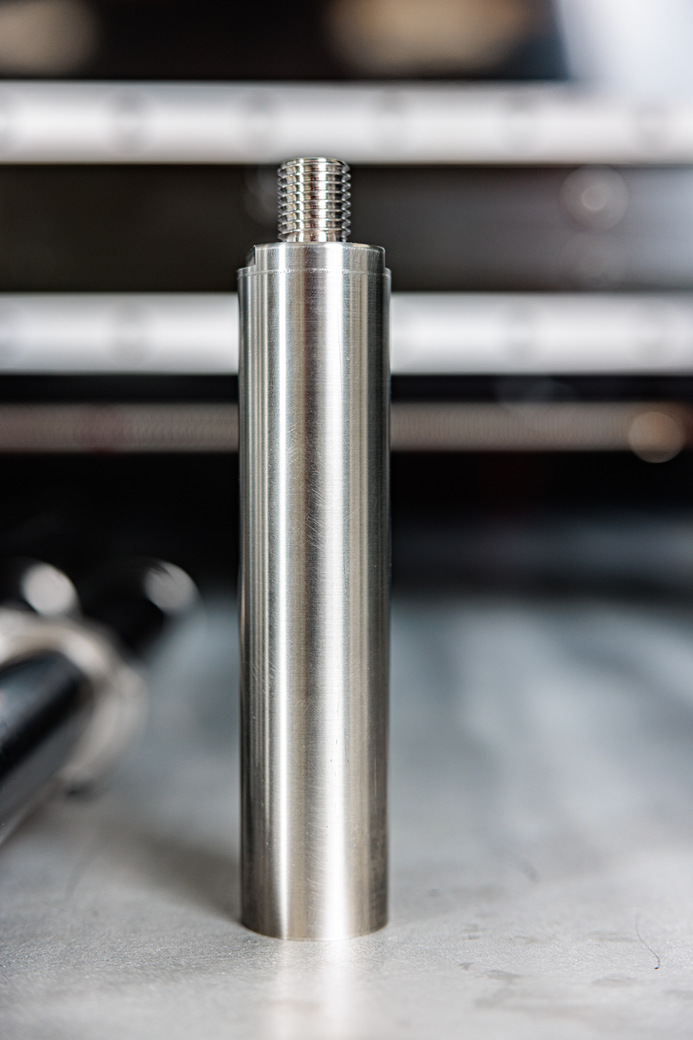

Today in the U.S. there is a crippling shortage of skilled welders in the precision manufacturing sector. Over 450,000 jobs opening in the welding field, go unfilled due to a lack of trained and skilled welders. Weldlogic Engineering has been tasked by a custom pneumatic manufacture to develop a system to significantly reduce or eliminate the high welding skill levels & costs required to make these very precise low distortion welds in today’s labor market.

SOLUTION

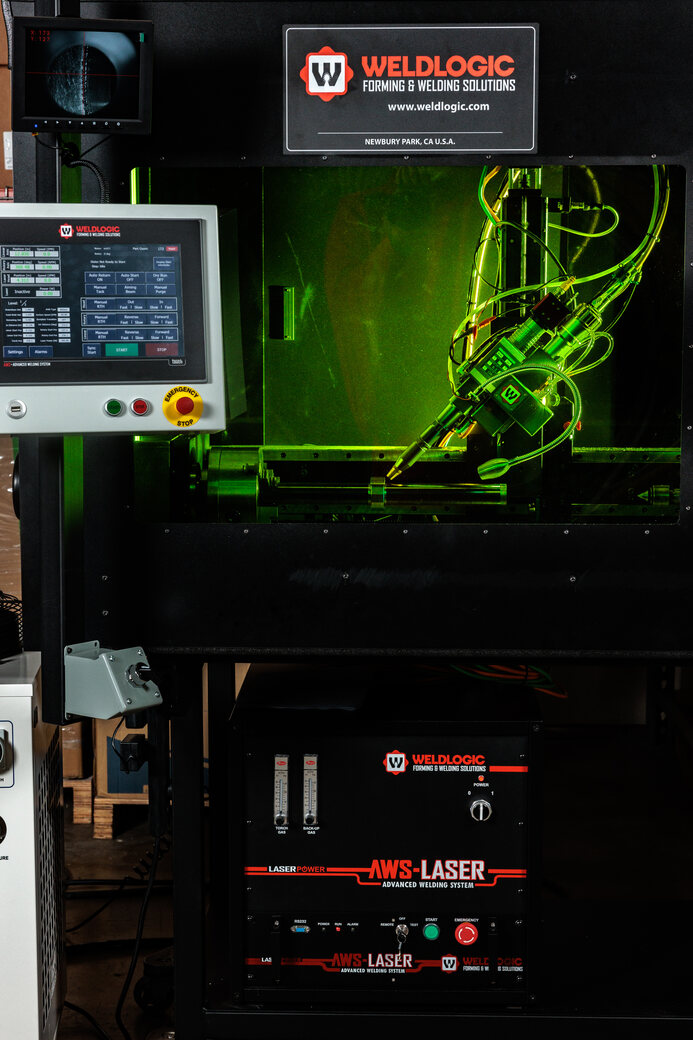

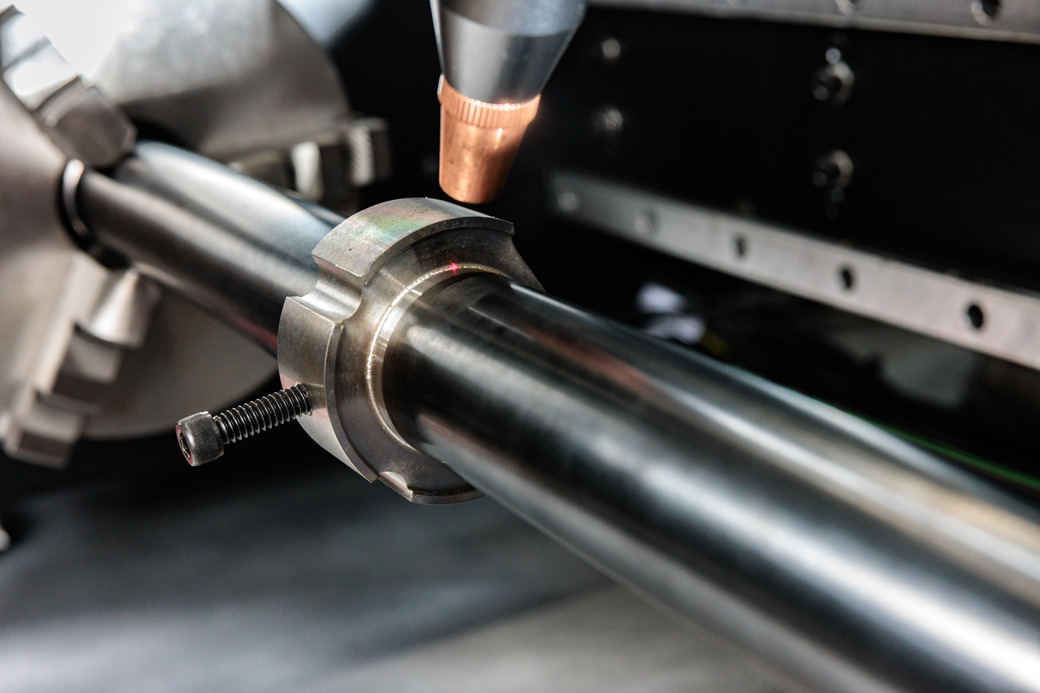

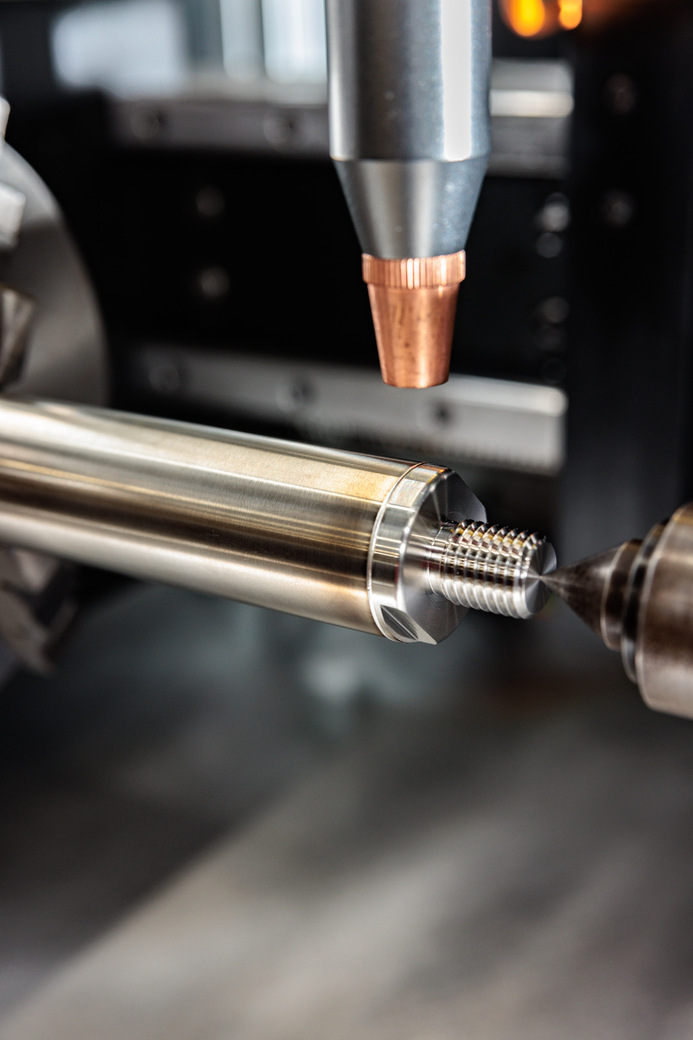

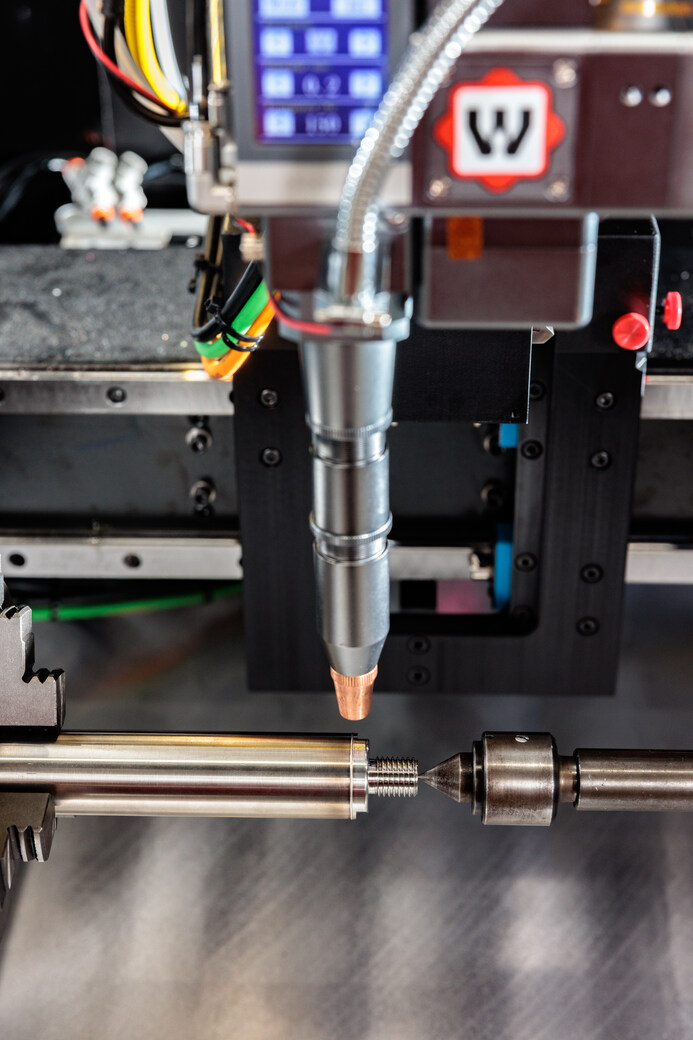

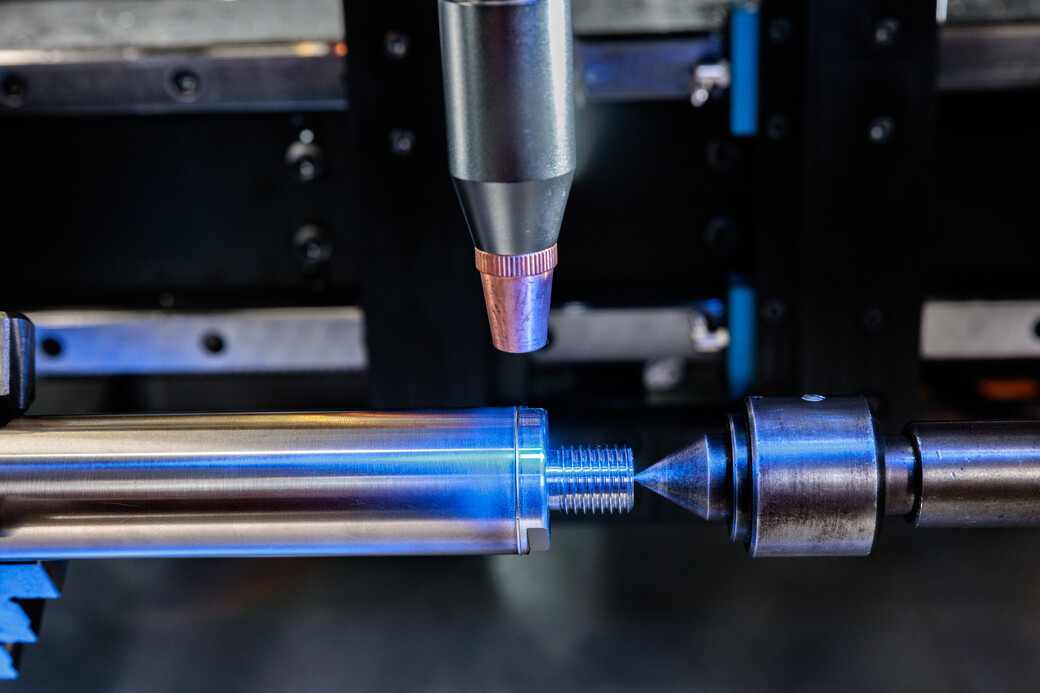

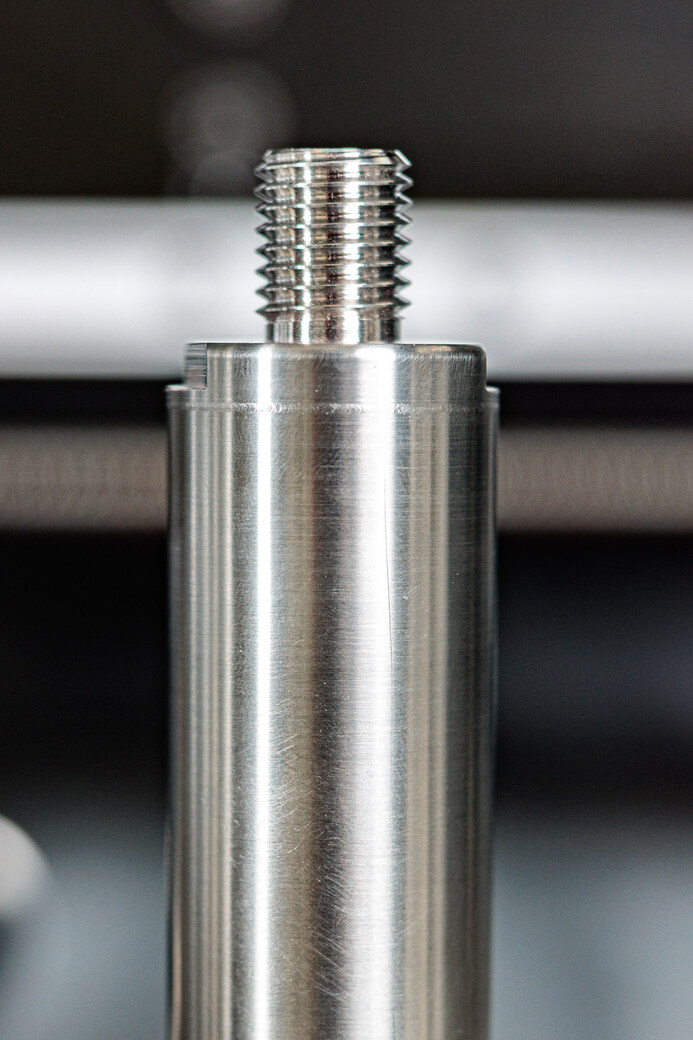

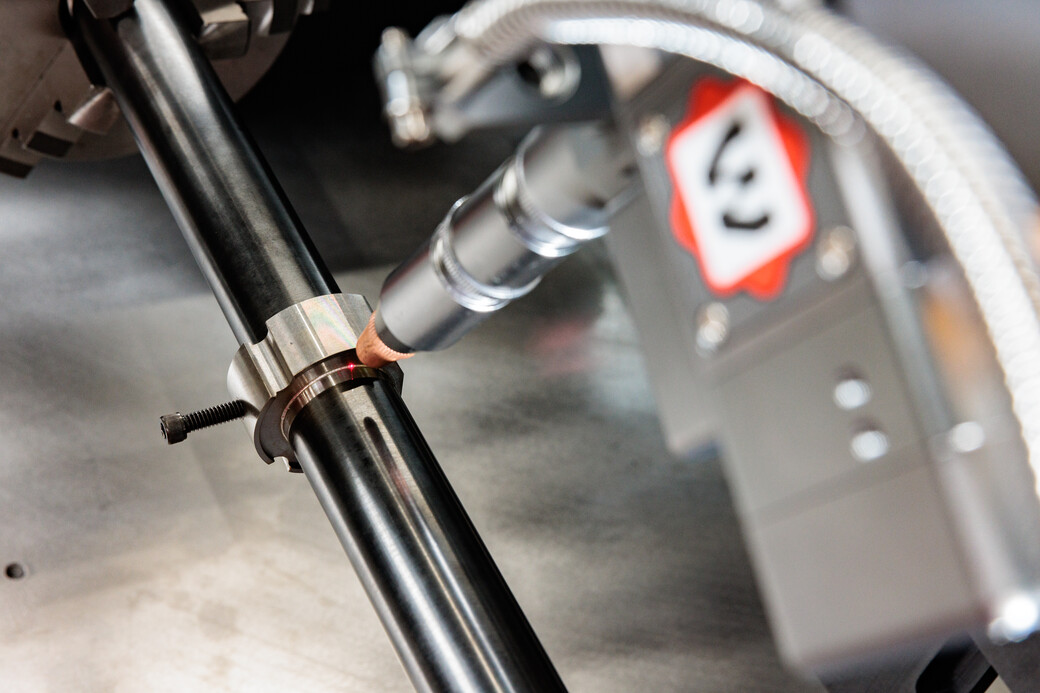

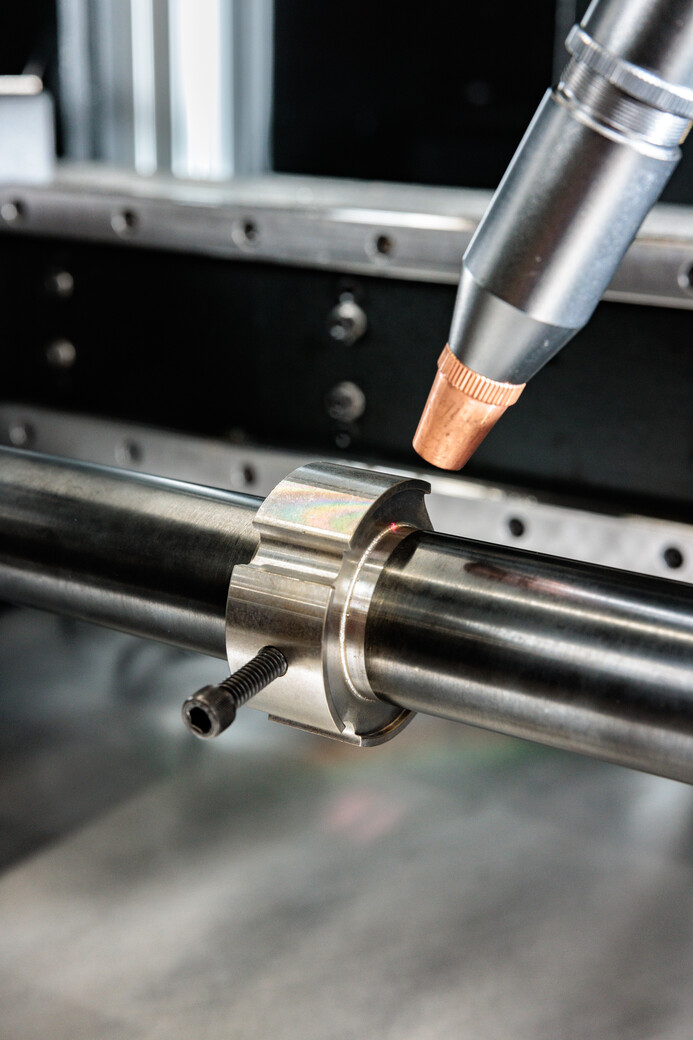

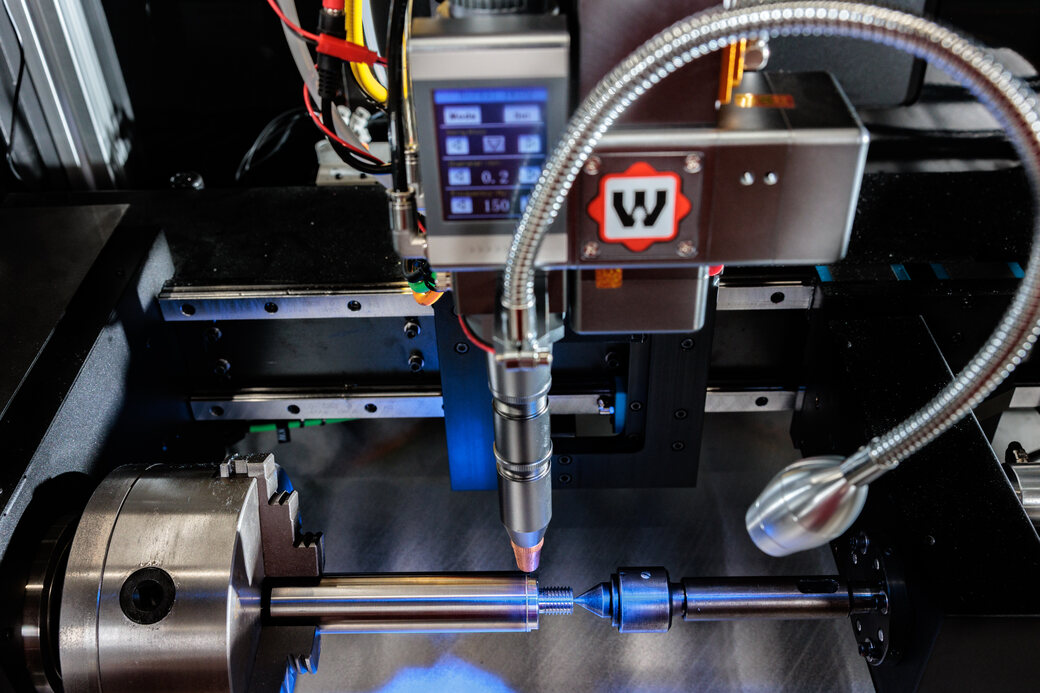

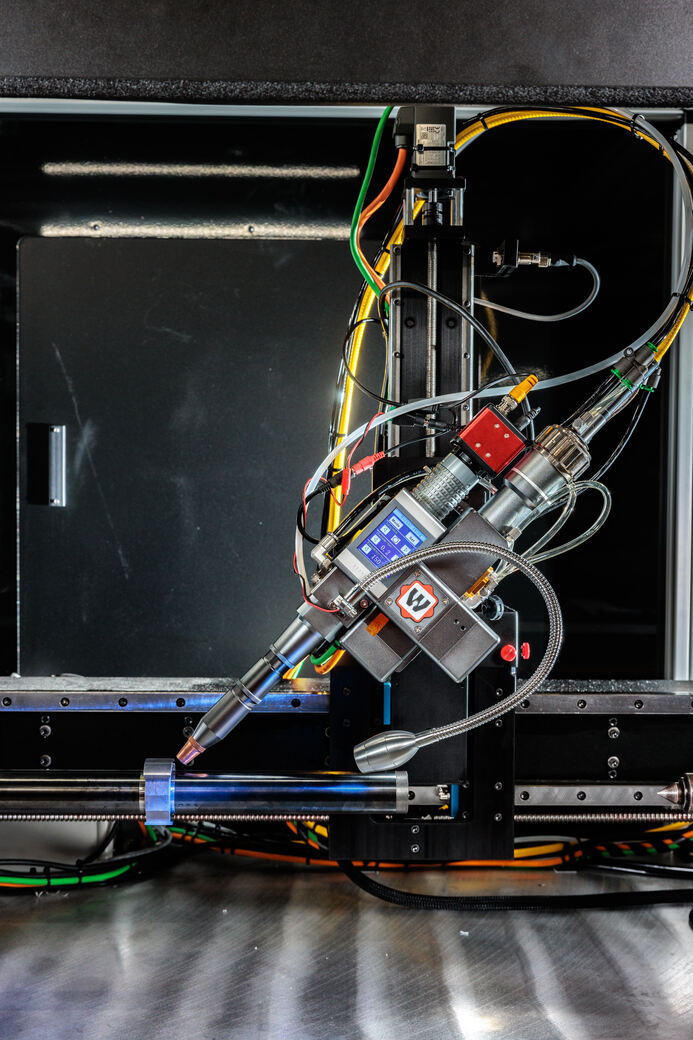

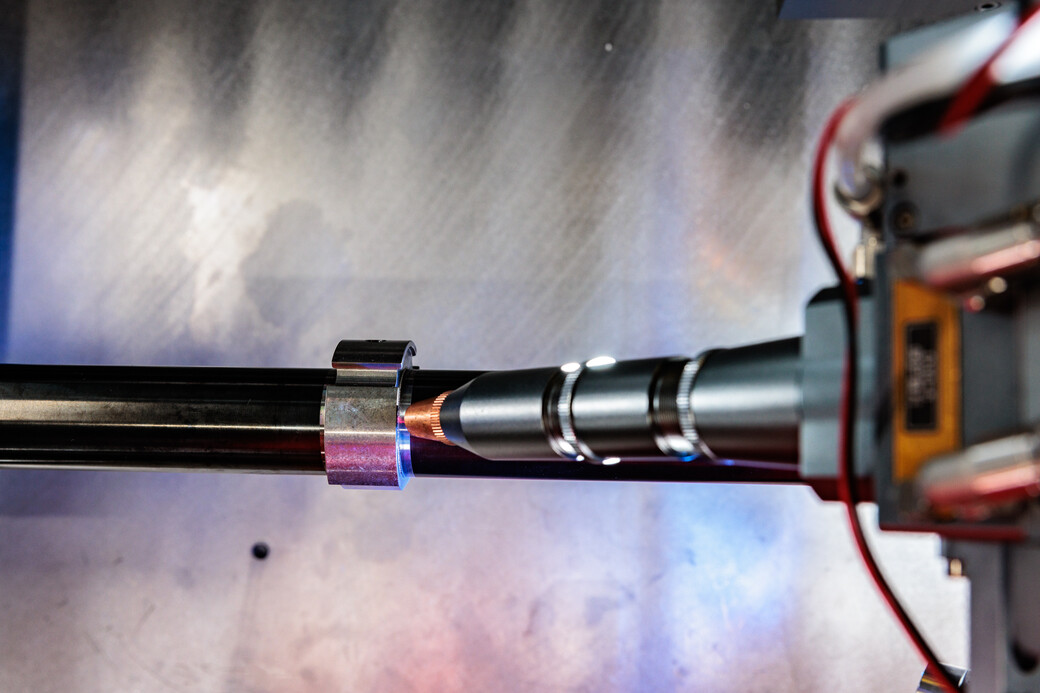

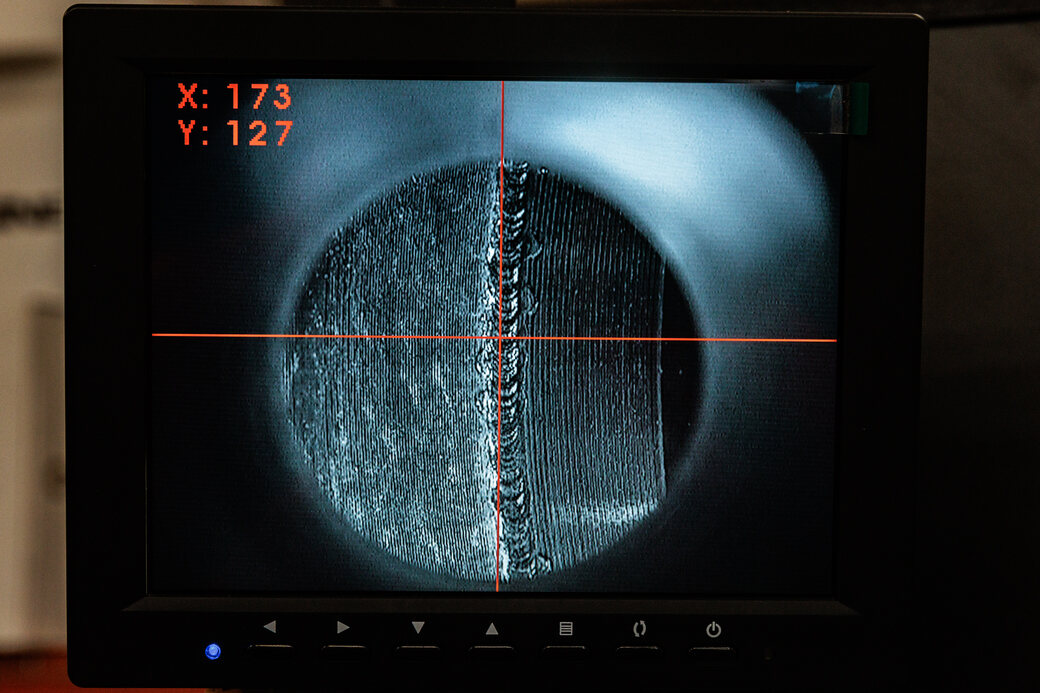

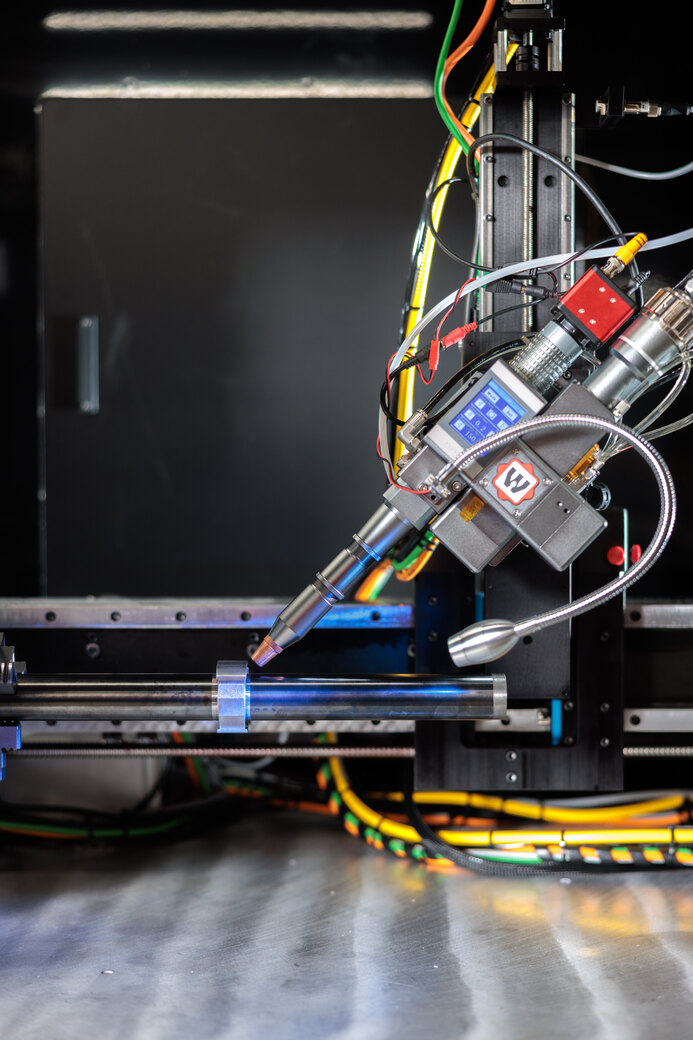

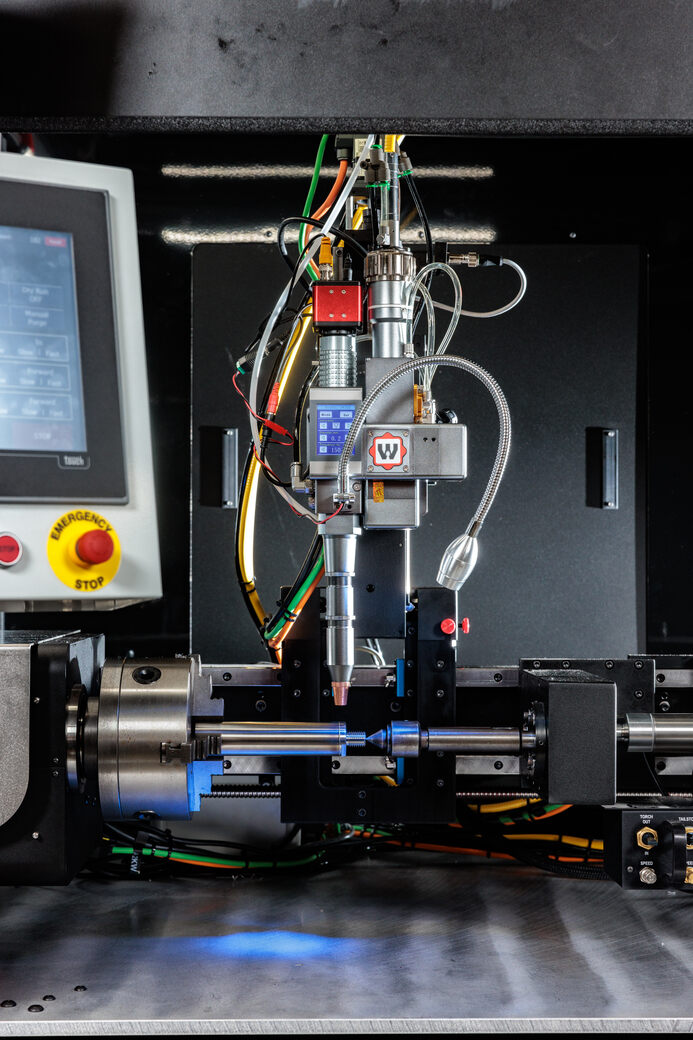

Design and fabricate a user friendly 3 axis weld cell to enable a wide range of diameters and lengths to be seal welded reliably using a system that saves and retrieves all the program to enable low heat input / low distortion automatic welds.

The system consists of the following Weldlogic standard products:

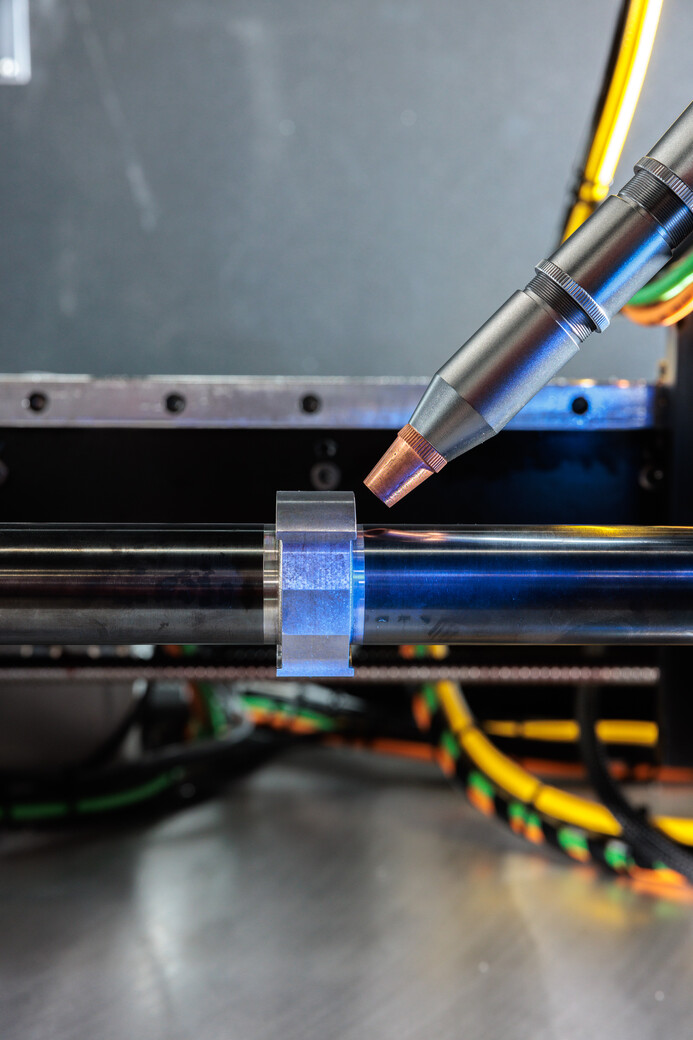

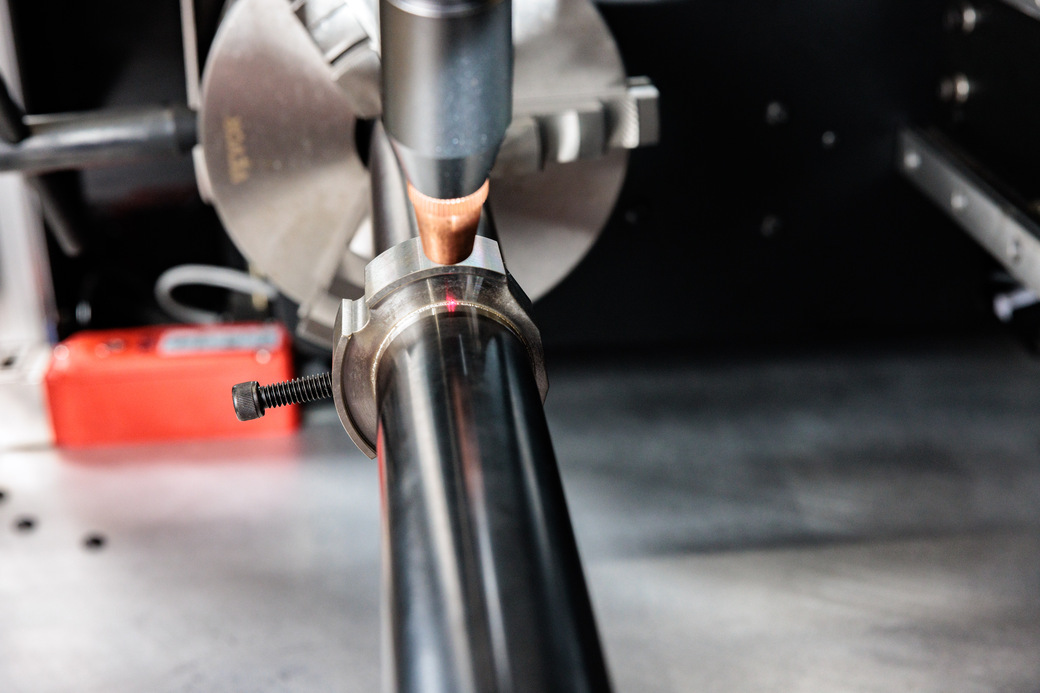

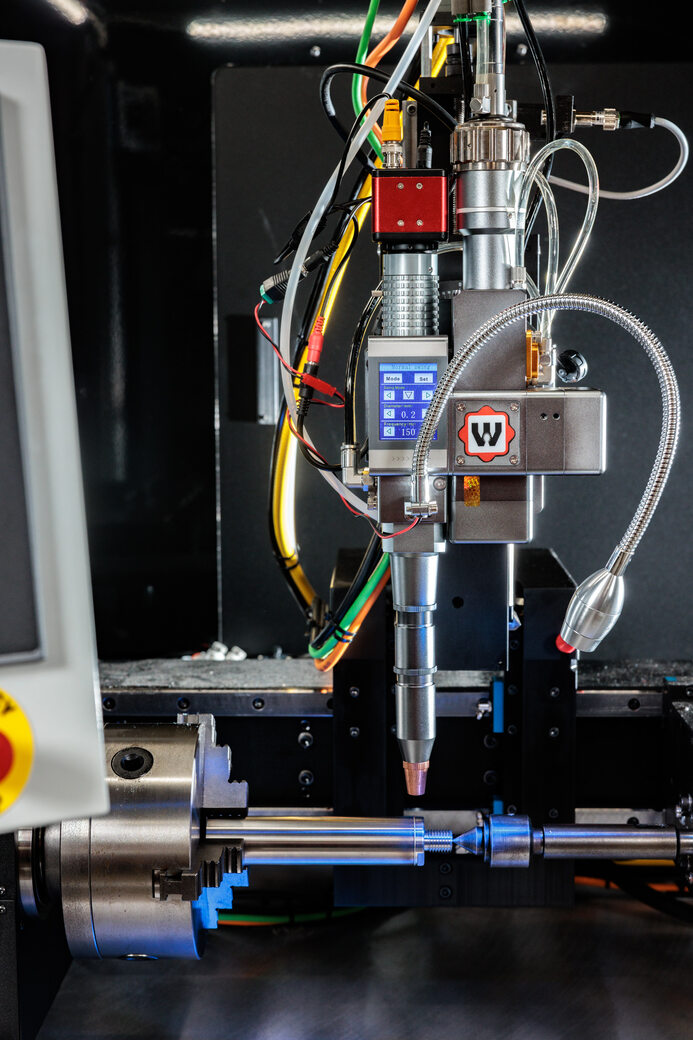

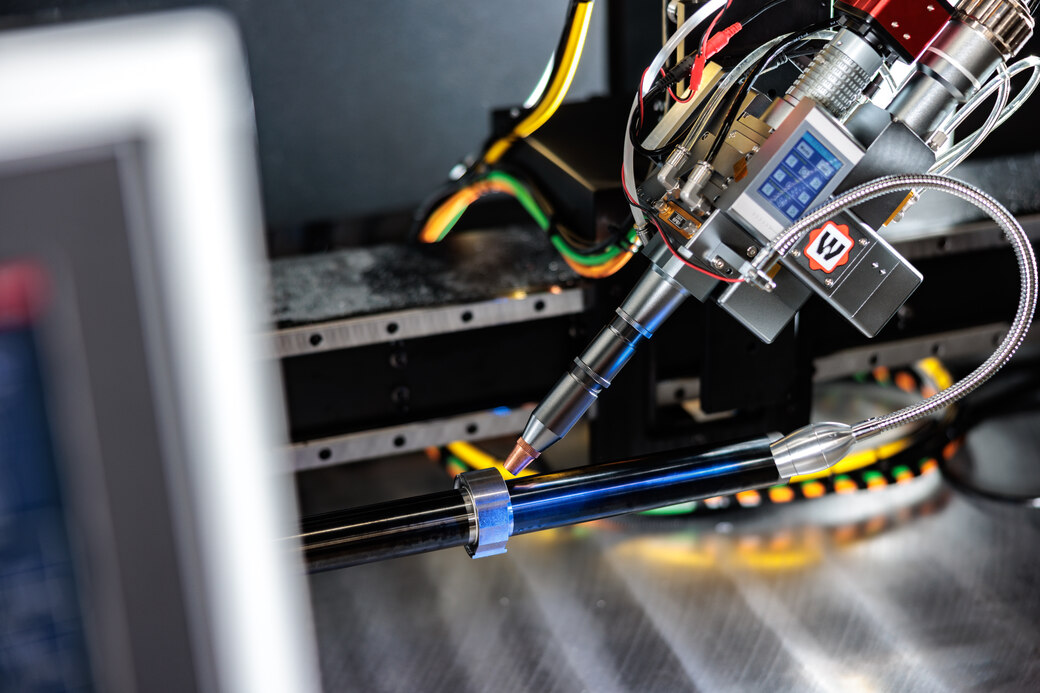

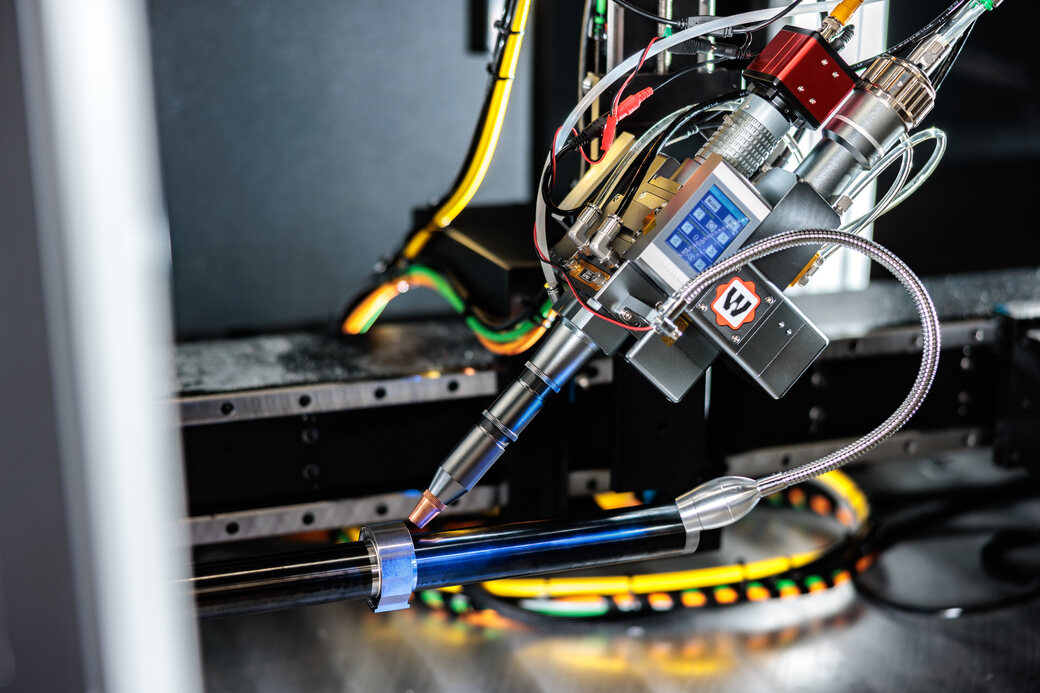

- PWL-15-60 Precision Welding Lathe AC Servo driven in 3 axis

- AWS-1000-Watt fiber laser and weld controller with memory

- Wobble Laser Head to widen or narrow the spot size

- 12″ HMI to program and operate system

- Workstation Table with Class #1 safety enclosure

- Exhaust / Filtration system to hepa filter

- Weld Process developed with training

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A