Introduction

CHALLENGE

This customer needed an automatic welding cell capable of handling both precision TIG and precision MIG welding across a variety of assembly types.

With rising production volumes and high labor costs associated with skilled welders, manual welding was no longer a scalable solution. The key challenge was developing a single platform that could support both welding processes while enabling fast, clean changeovers — especially with MIG, where spatter control was critical.

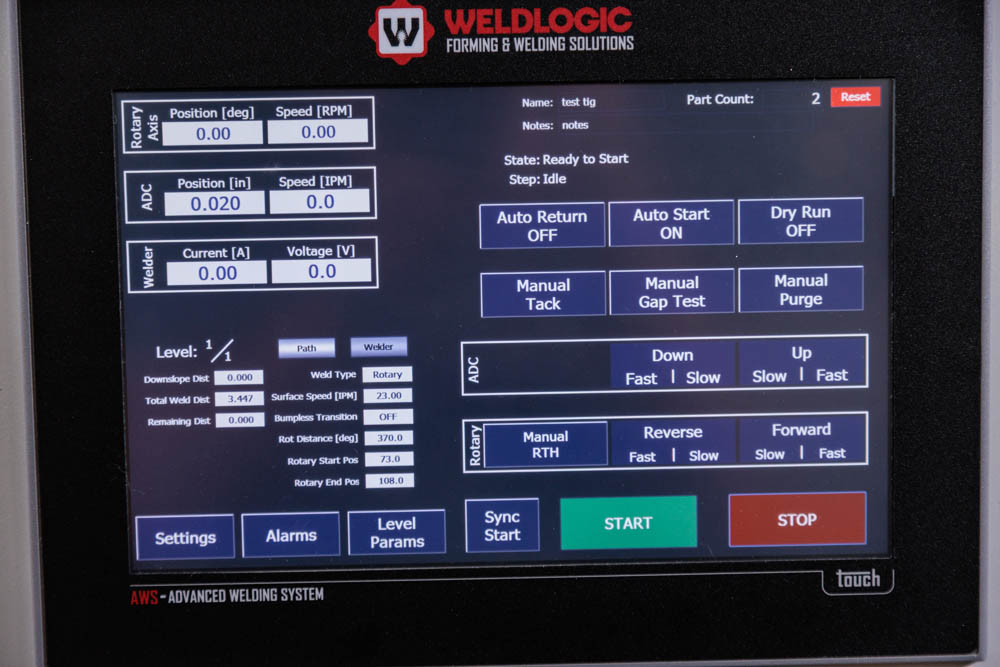

An additional requirement was making the system intuitive enough that a low-skill operator could run it efficiently, maintaining a throughput of 60+ parts per hour.

SOLUTION

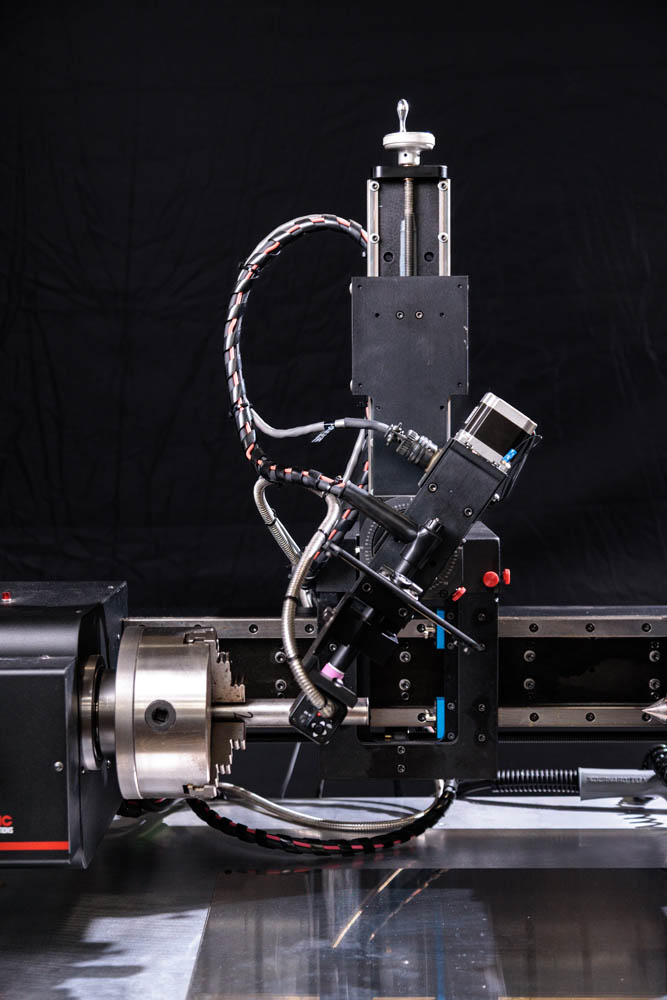

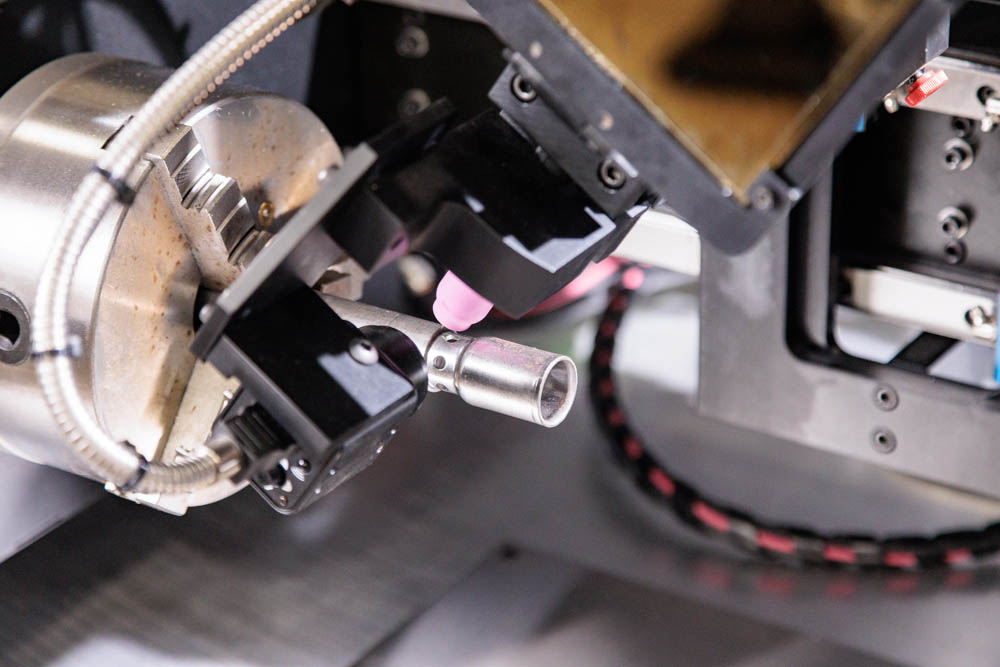

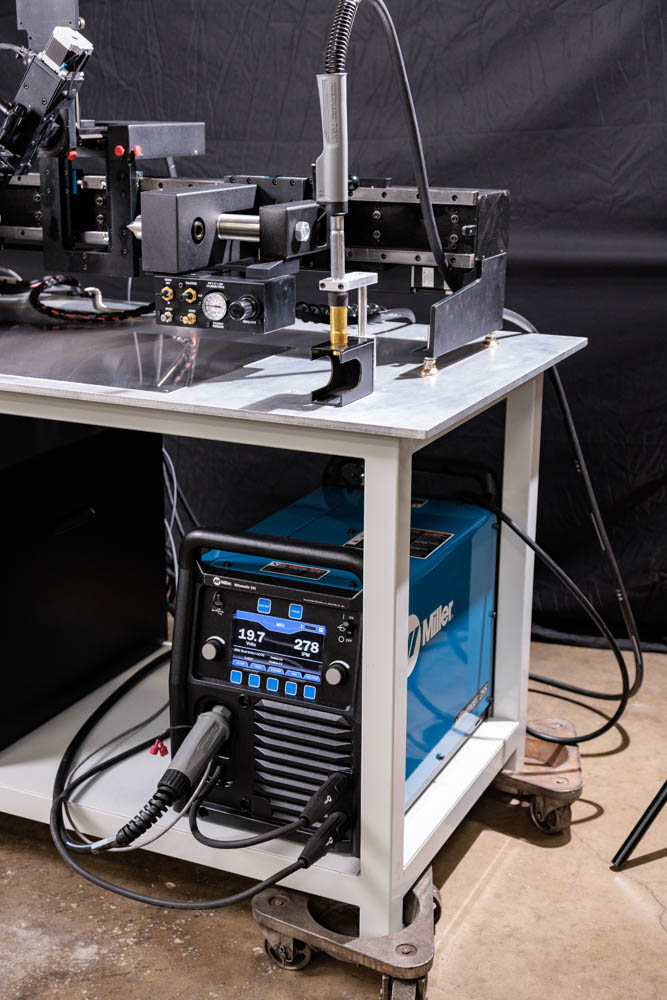

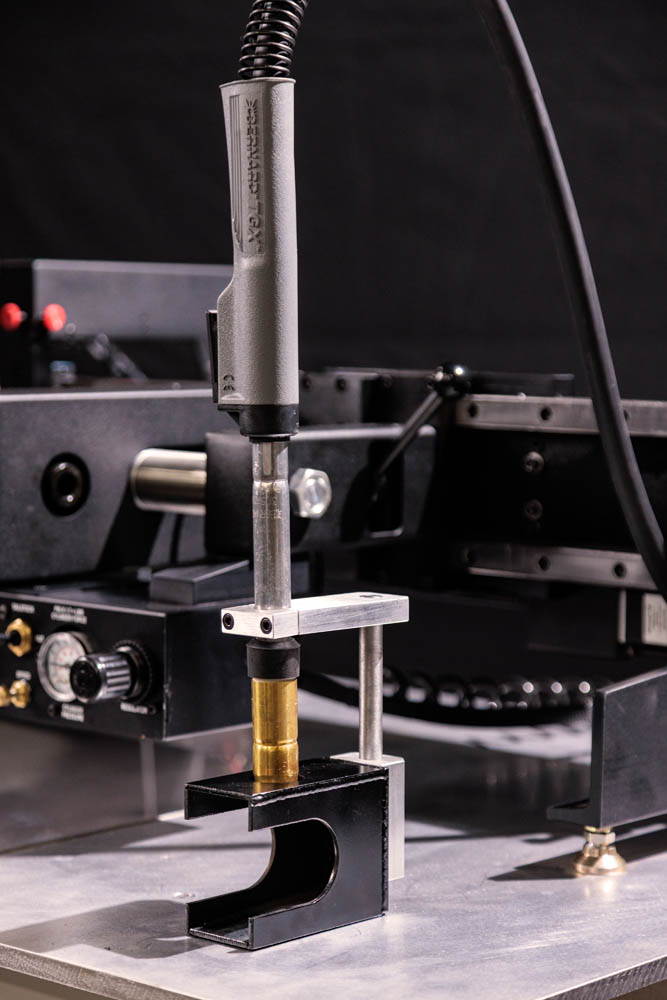

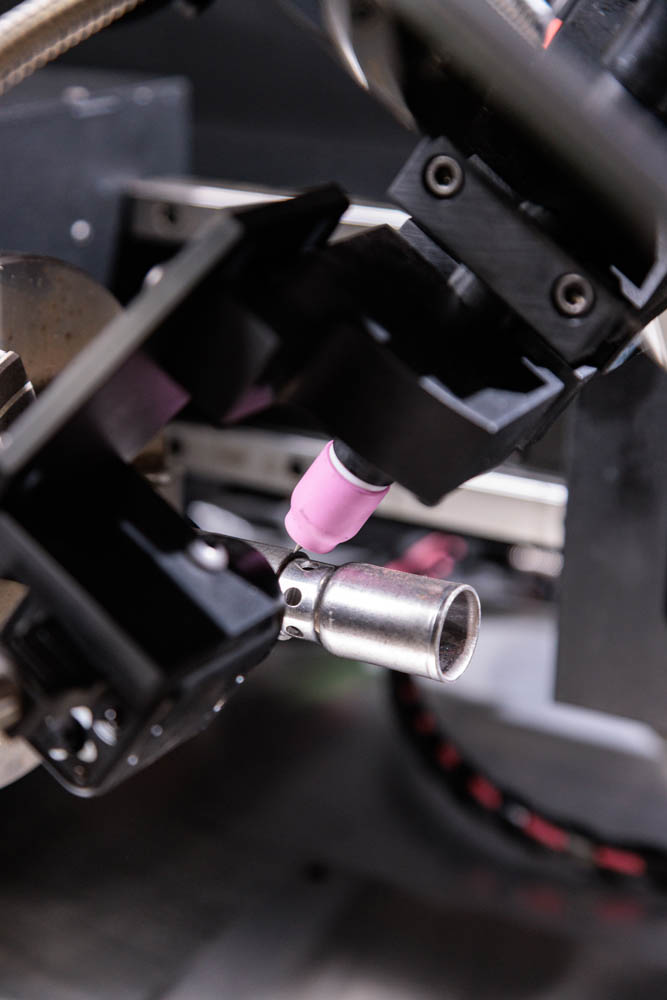

Weldlogic’s Mechanical and Electrical Engineering teams, together with our software developers, created a flexible dual-process welding cell that seamlessly switches between TIG and MIG torches. The software was also developed to interface directly with the Miller MIG power supply, ensuring full process control from a single interface.

The result is a computer-controlled Dual Process Welding System designed for fully automated, high-speed circumferential welds — with the flexibility, ease of use, and performance required to meet today’s production demands.

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A