Introduction

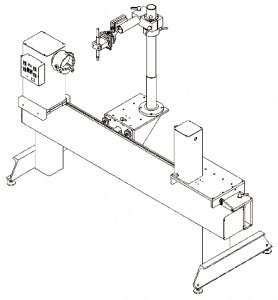

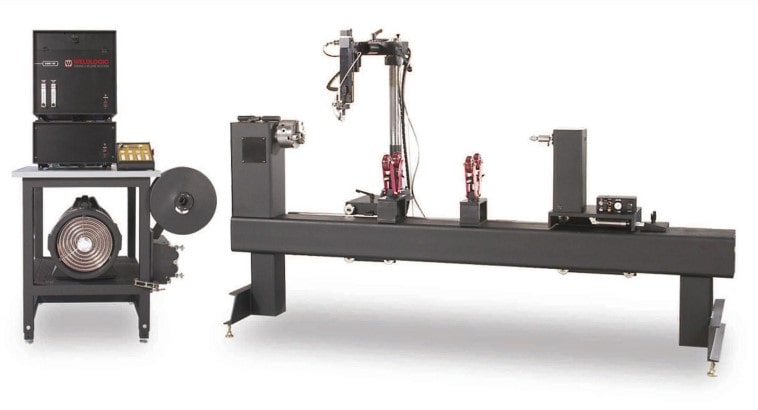

Weldlogic Engineers combine the AWS-400 Ampere Computer Controlled Power Supply with Arc Voltage Control, Wire Feed, Travel Rate and Oscillation to enable the highest Quality Welds integrated to our CWL-30/36 Circumferential Welding Lathe.

The CWL product has many options to tailor this precision positioner to your specific application requirements.

Video

Gallery

Features

- Windows Based Program

- 400 Amperes Capacity

- Arc Voltage Control

- Multiple Level Programming

- Weld Process Development

- Wire Feed

- Arc Oscillation

- Dual Gas Control with Sensors

- TIG/PLASMA

Specifications

N/A

Applications

CWL-30/36 Features

- Heavy-duty Head Stock

- 400 Ampere Ground

- 1000 Lbs Capacity

- All Steel Construction

- Dual Spindle Capacity

- T.I.R. 001”

- Speed Accuracy ± .5%

- Rigid Torch Arm with Slider

CWL Standard Features & Specifications:

- Detachable Fixture Control Pendant

- Headstock: Positive Helical Gear Drive with Monolithic rigid all steel frame

- Bed: Rigid – all steel construction. Saddle & Tailstock ride on precision high capacity

preloaded Bearing System - Tailstock: Rigid all steel construction with full range of alignment adjustment(s)

- Independent Tailstock Pusher System – maintains alignment over full range of thrust

- Torch Head swings to rear of tool for clear access when loading & unloading workpiece

- Detented and Locking Torch Tower Head Pivot

- Input voltage: 100/125 200/250 VAC 50/60 Hz 100 VA

- Shop Air: 90 PSI – filtered

- Speed range .01 – 30.00 RPM

- Speed accuracy: + .5%

- T.I.R. .001 in .025 mm

- Weld current capacity: up to 400 Amps

- Spindle through hole: 1.27 in 3.22 cm

- Tailstock stroke 3.00 in 76 mm

- Tailstock force: 500 lbs. 2200 N

- Workpiece weight capacity: 1000 lbs. 440 kg

Options for Weldlogic’s Circumferential Welding Lathe CWL

Typical options:

Headstock

- Rotary spindle ID gas purge

- Up to 2.00” (5.1 cm) Spindle through hole

- Load capacity to 1,000 lbs (454 kg)

Tailstock

- Rotary gas purge

- Up to 2.00” (5.1 cm) spindle through hole

- Thrust loads to 500 lbs (2,227 N)

- Dual Head Stock with Spindle

Torch Tower

- Motorized z-axis

- Motorized torch mount rotary stageAdditional Options:

- Workpiece Steady Rest(s)

- Custom Tooling to hold / locate workpiece

- Computer controlled turn-key systems

- Custom designed positioner

Ask our experts about your unique challenge

Previous Product

PWL-15-36 Dual Spindle Precision Welding Lathe