Introduction

CHALLENGE

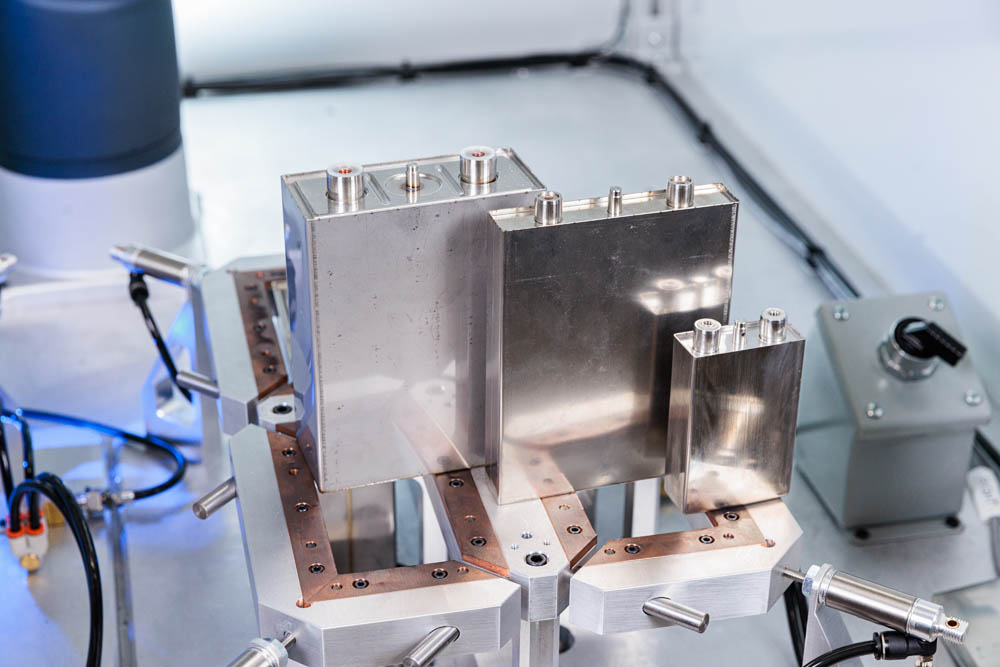

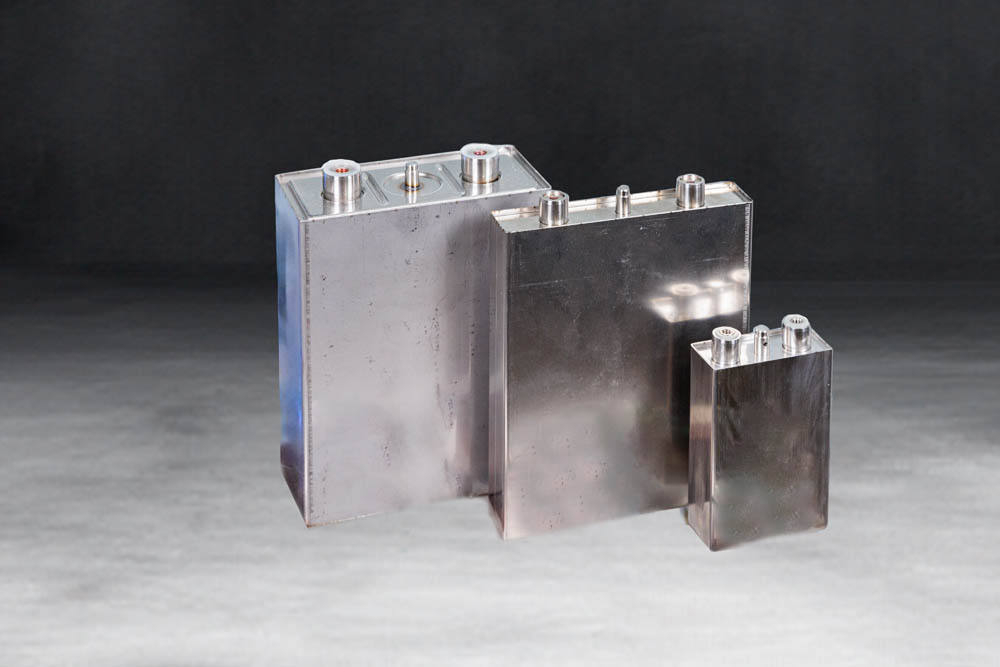

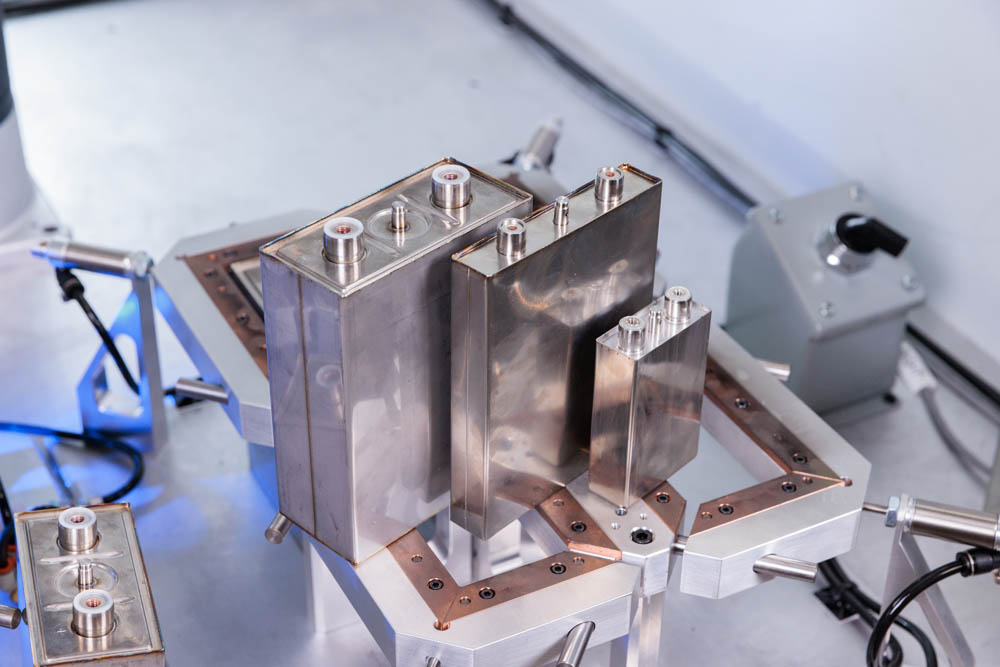

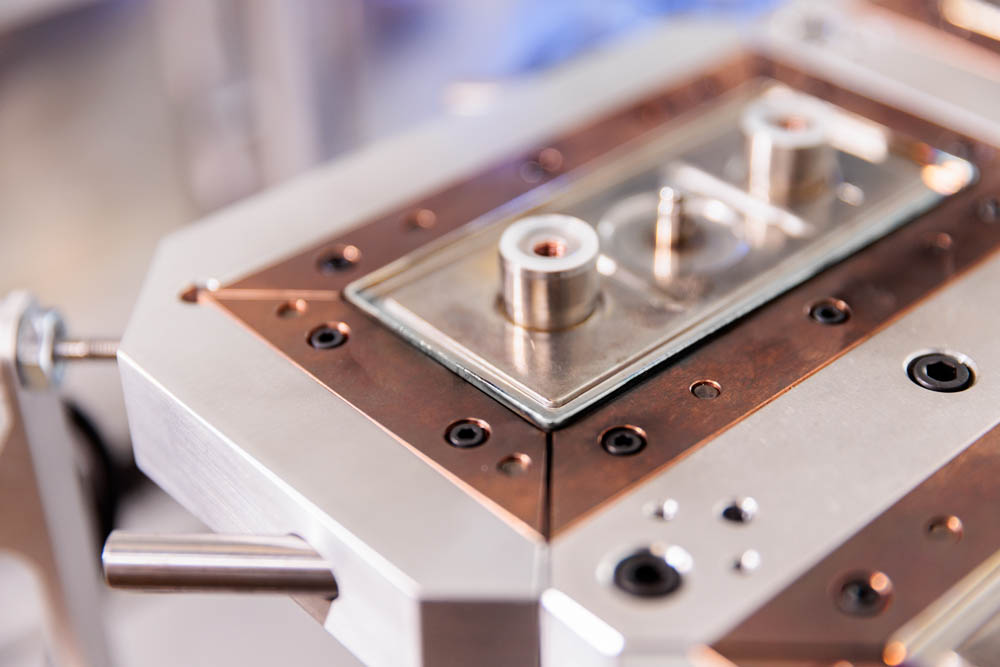

A valued customer was previously using manual GTAW (TIG) welding to create hermetic seal welds on thin-wall stainless steel cans and lid assemblies used in high-reliability military battery cells. This process required highly skilled welders and came with significant challenges in heat control, weld consistency, and throughput.

With a shrinking pool of skilled welding labor — and over 450,000 unfilled welding positions reported across the U.S. — the customer needed a more reliable, automated solution to reduce labor dependency while maintaining the stringent quality required for hermetic military-grade battery enclosures.

SOLUTION

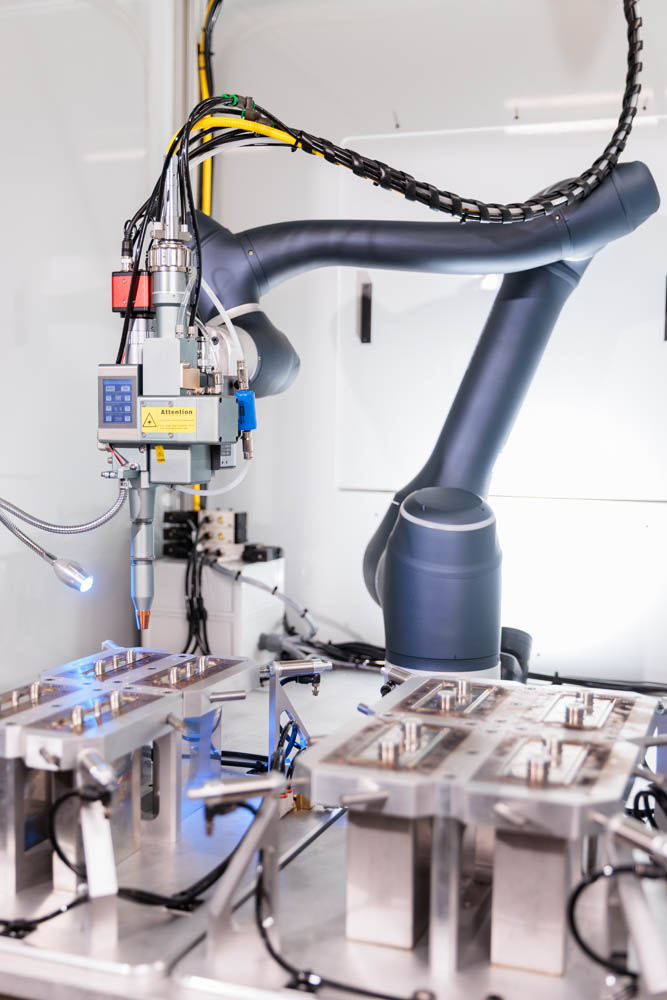

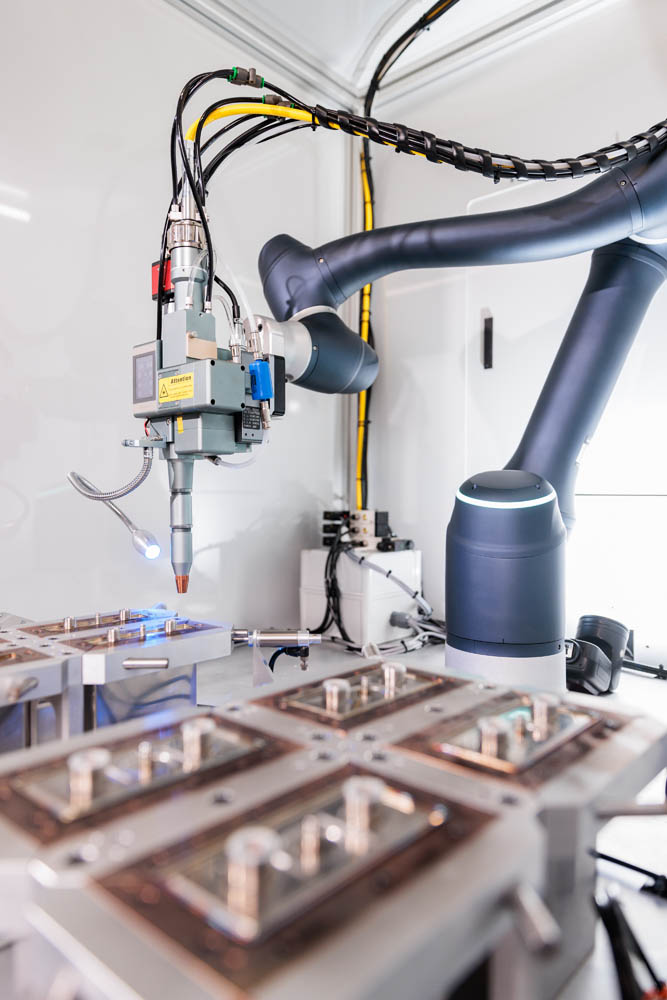

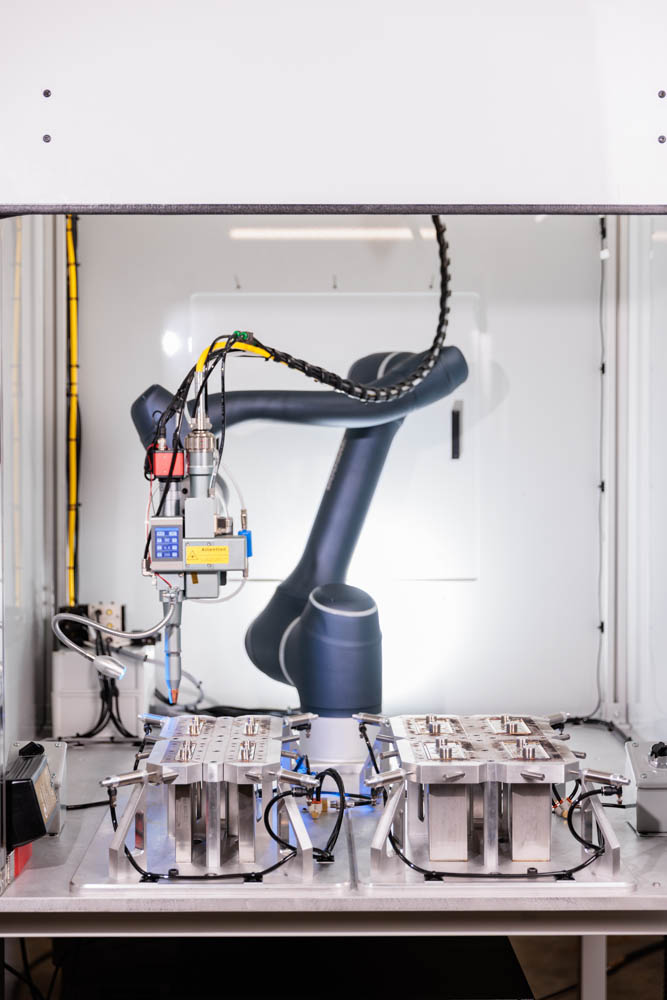

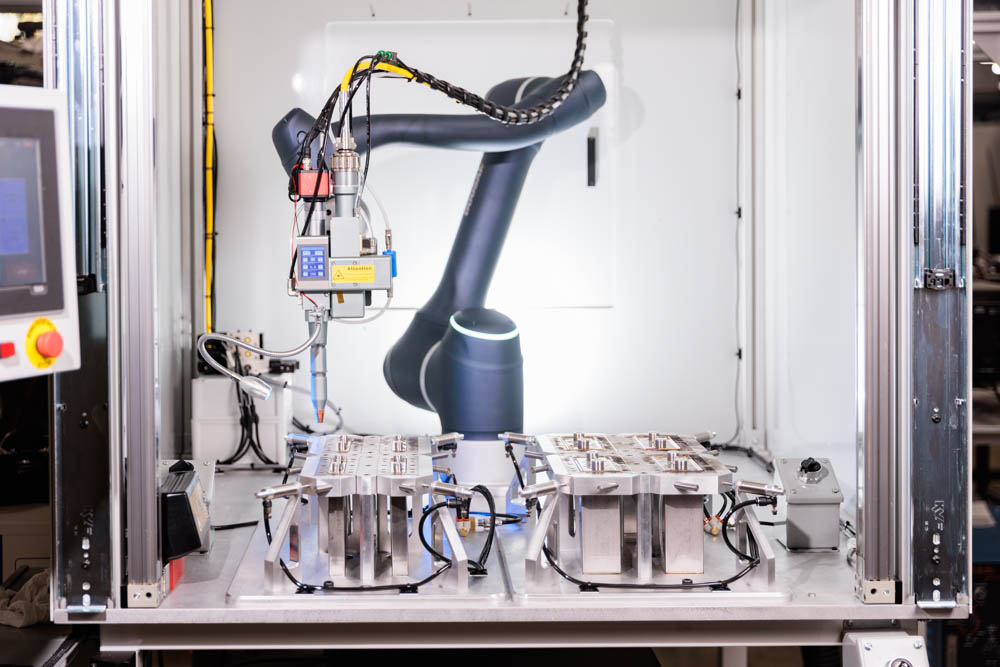

The Weldlogic Welding Services Group (WSI) partnered with the customer to develop and validate a low heat input laser weld process that eliminated the need for skilled manual welding. Once validated, Weldlogic Engineering designed and built a robotic laser weld cell to automate the production process.

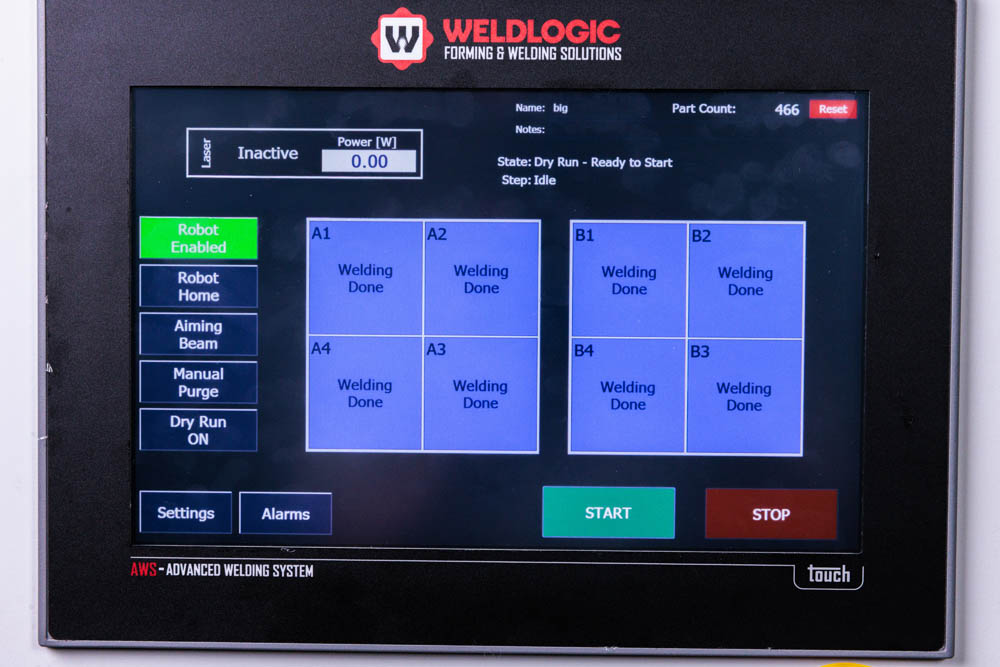

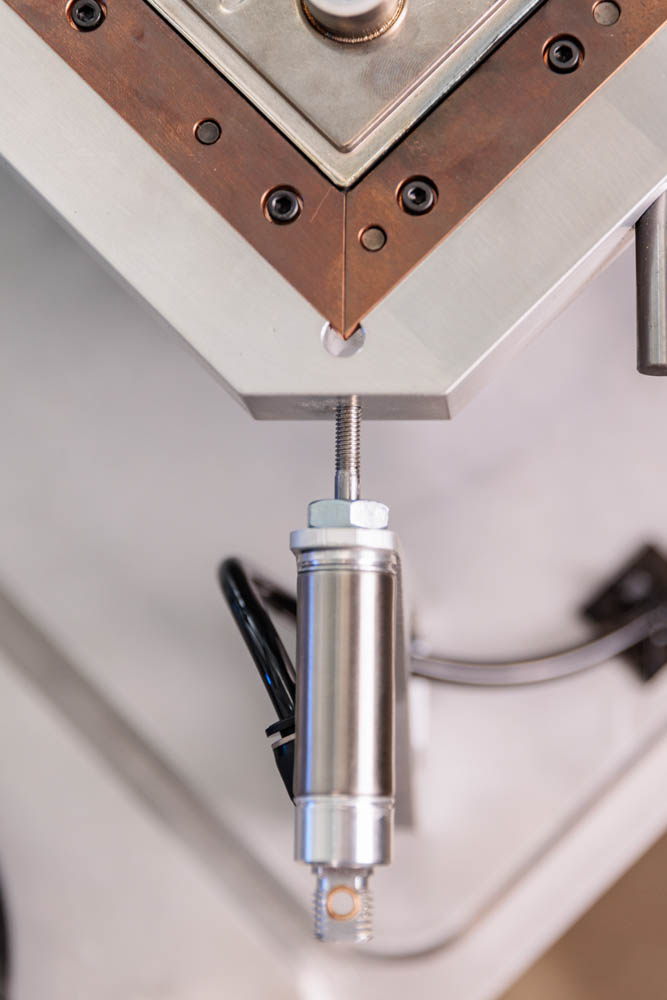

This system features a precision tool plate with multiple cell pockets, each equipped with a proximity sensor. These sensors signal the robot to apply the correct laser weld schedule if a part is present — or skip the pocket if not. The process is seamless, accurate, and repeatable.

The result is a high-production laser weld cell that consistently delivers low-heat, hermetic welds — now operable by a standard production operator instead of a highly trained TIG welder.

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A