Introduction

CHALLENGE

A long-time Weldlogic customer specializing in high-quality metal bellows recognized a growing problem: their production relied heavily on highly skilled, highly experienced welding operators to perform repetitive, micro-precision assembly work.

With skilled welders retiring—and a national shortage of over 450,000 unfilled welding positions in the U.S.—the manufacturer faced an urgent staffing and production challenge. Replacing decades of welding expertise had become increasingly difficult, putting output and consistency at risk.

SOLUTION

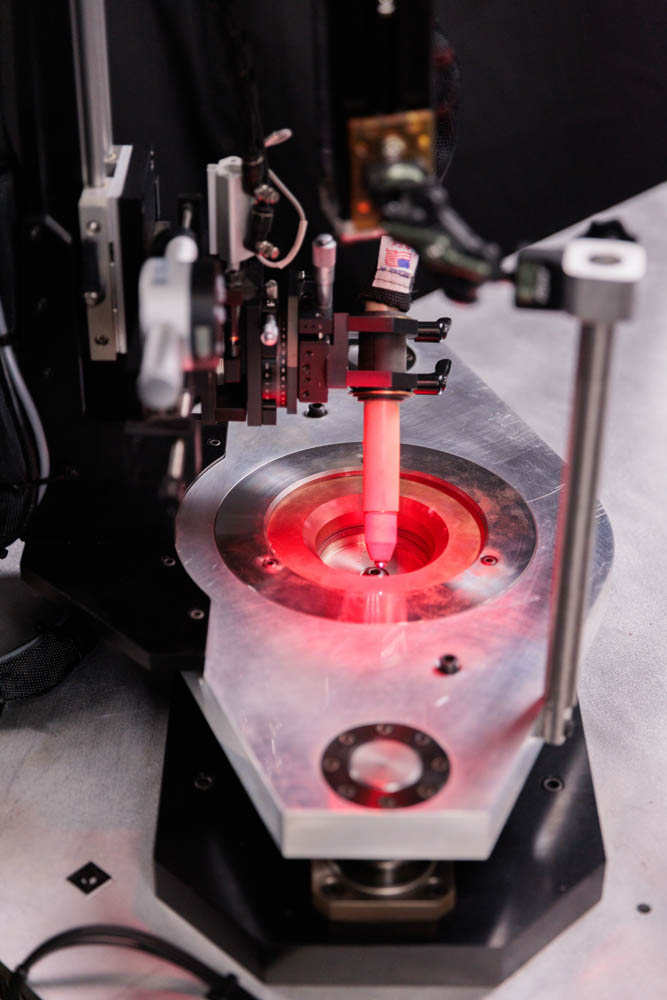

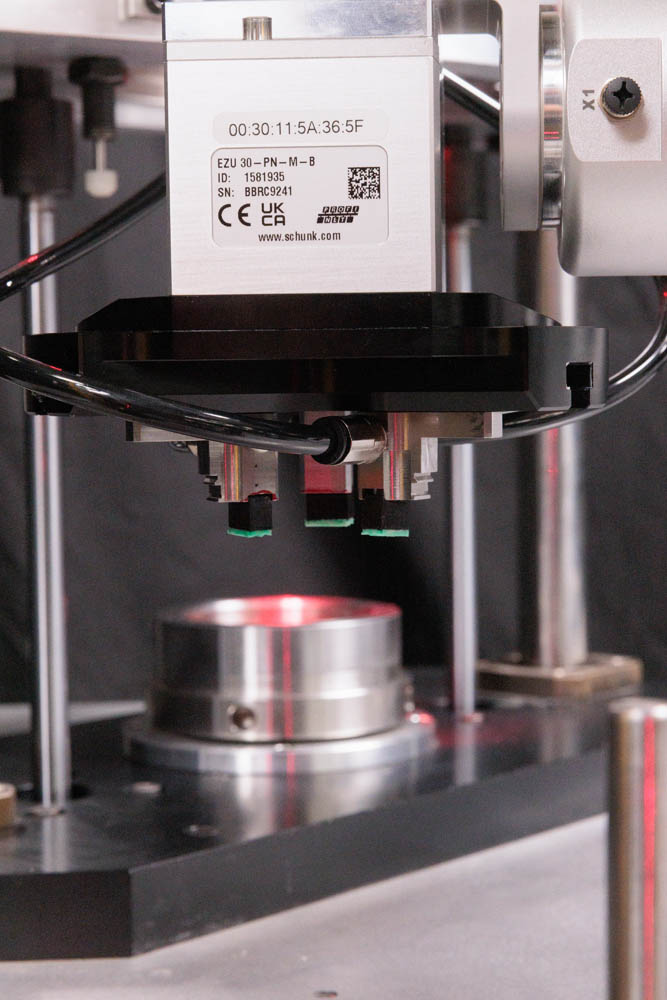

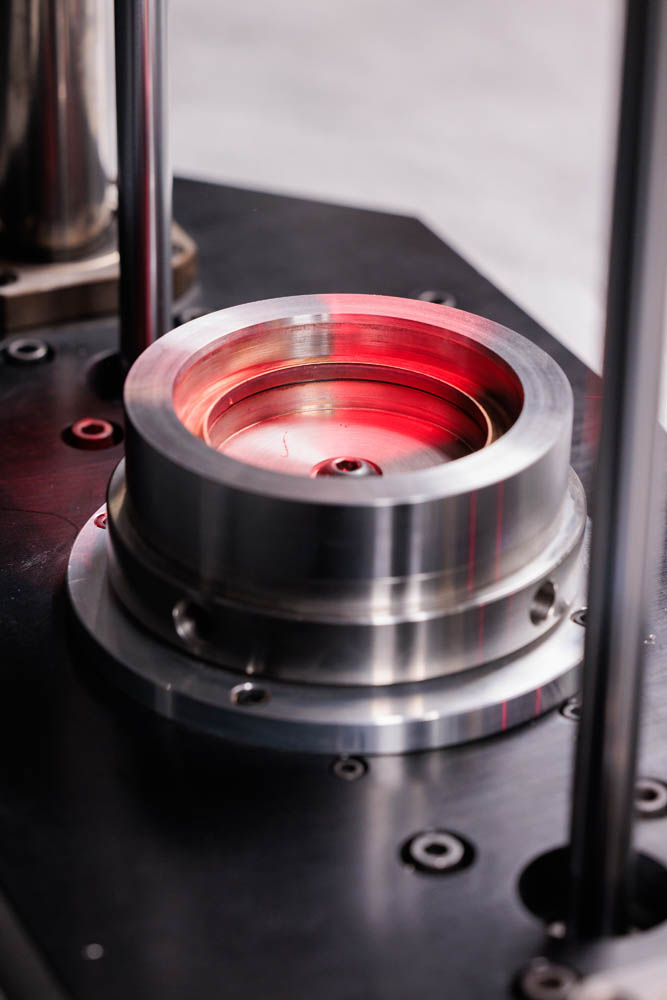

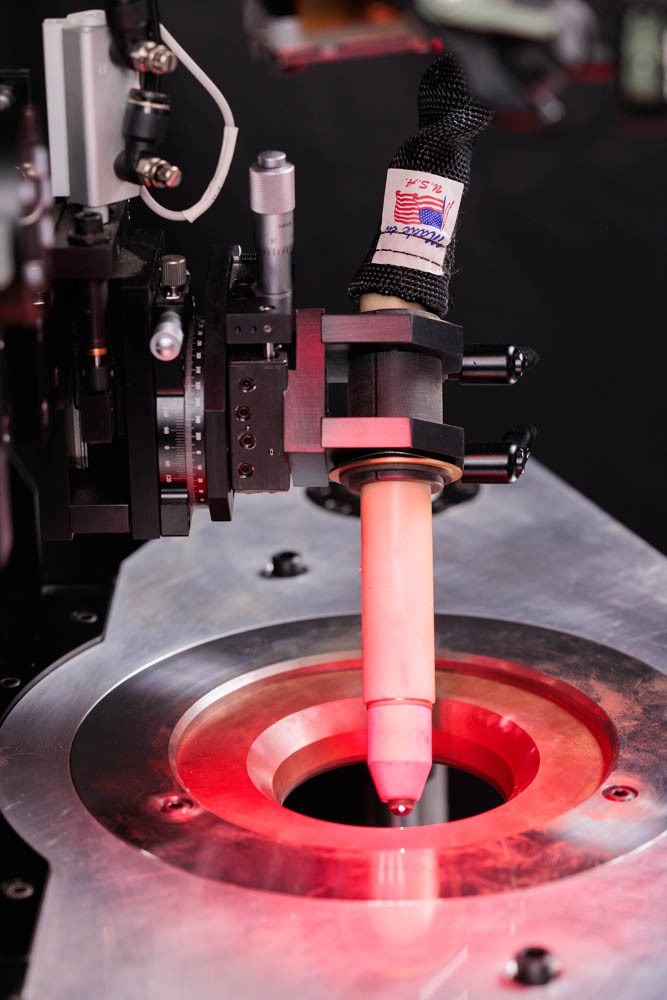

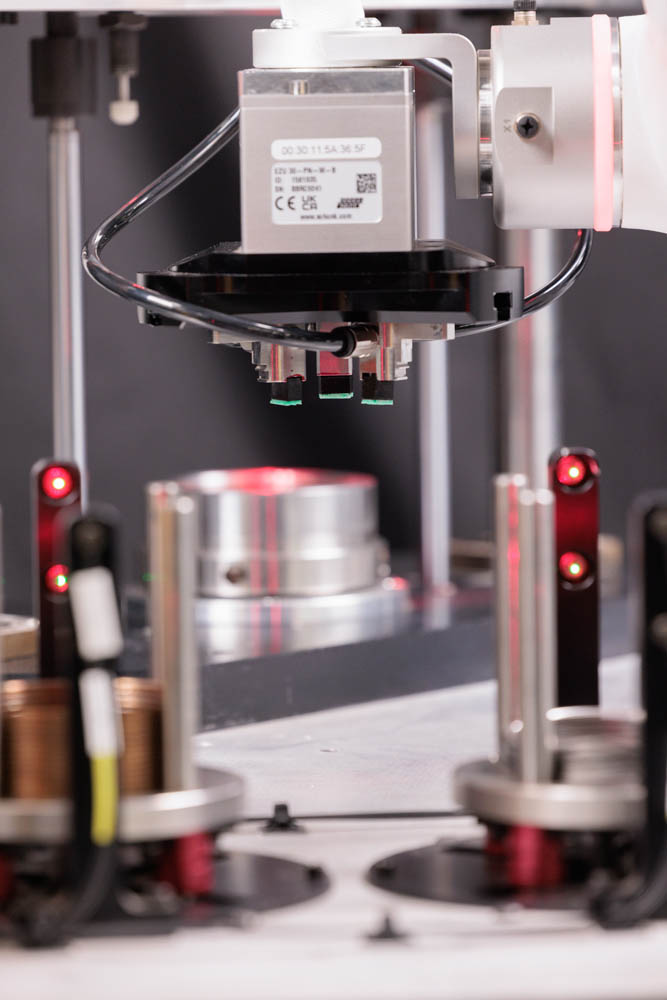

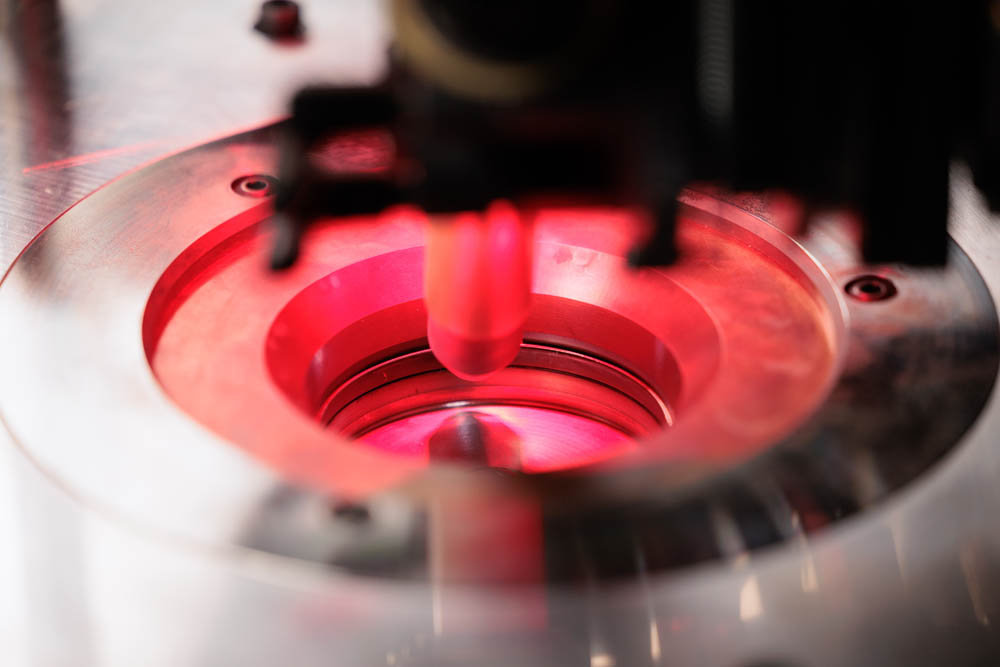

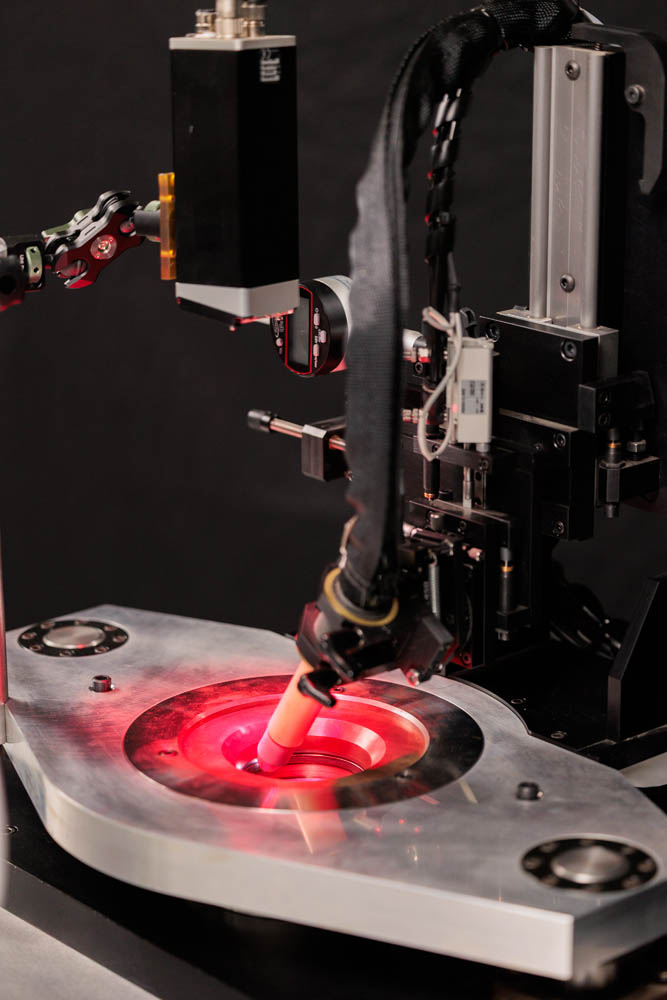

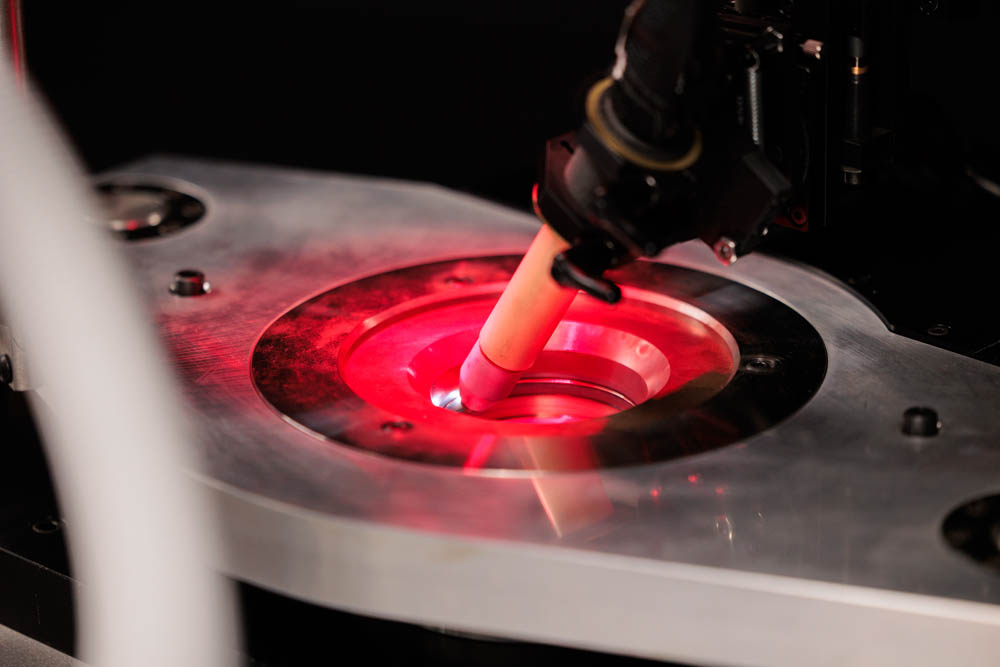

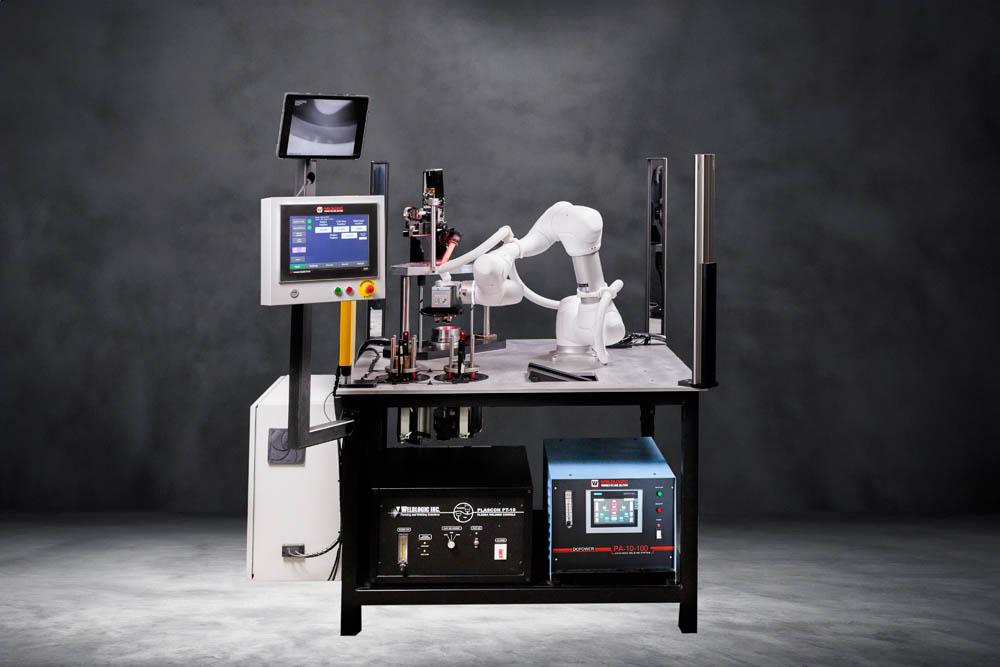

Weldlogic Engineers conducted a full evaluation of the technical and labor challenges and designed a specialized robotic pick-and-place system to load bellows and chill rings into a Weldlogic-designed I.D. Weld Cell.

To meet the delicate precision requirements, our engineering team developed several custom subsystems, including:

- A vacuum handling system

- A precision parts feeding system

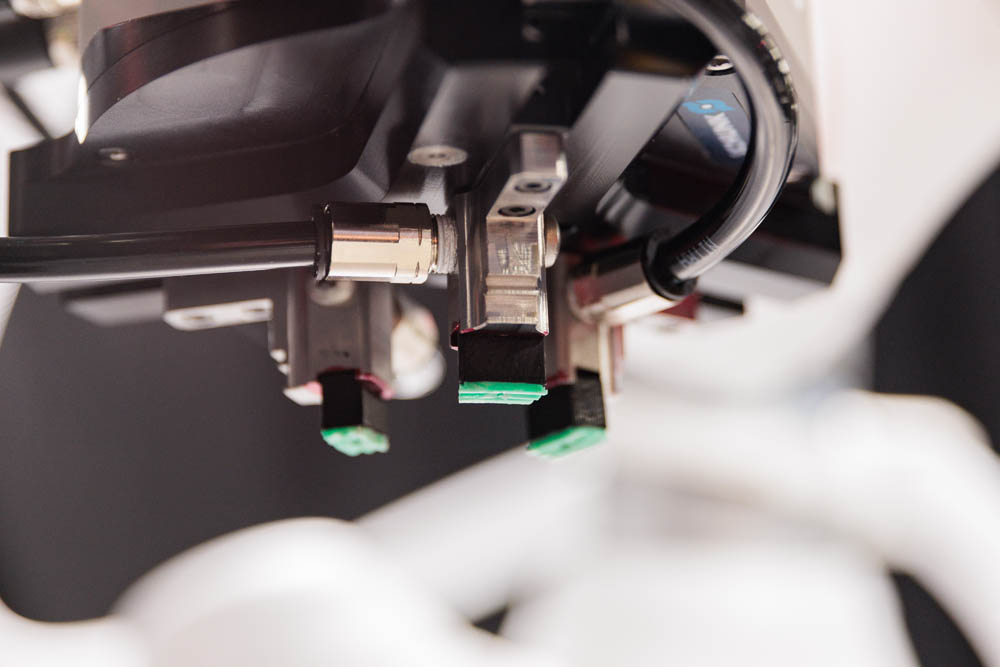

- A custom gripper/end-effector

- An integrated camera vision system

- A specialized welding torch

Many of these components required in-house innovation to meet performance and accuracy demands.

The result is a fully automatic I.D. Bellows Welding System that runs production without the need for a human operator—solving the skilled labor shortage and delivering consistent, high-quality welds every cycle.

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A