Introduction

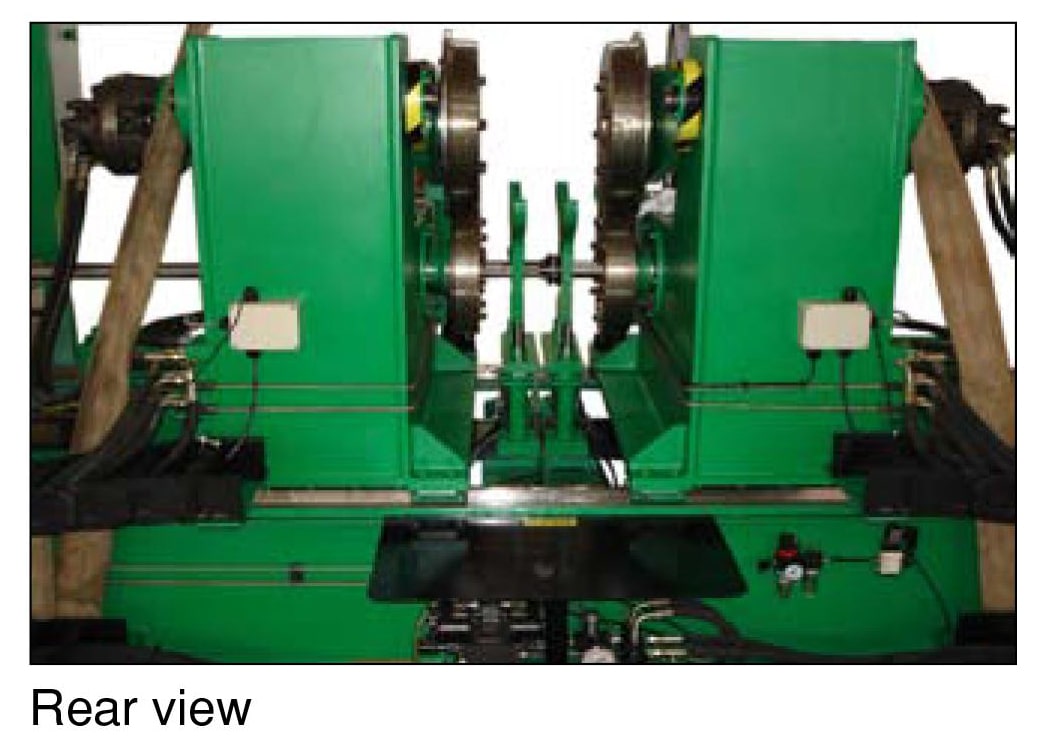

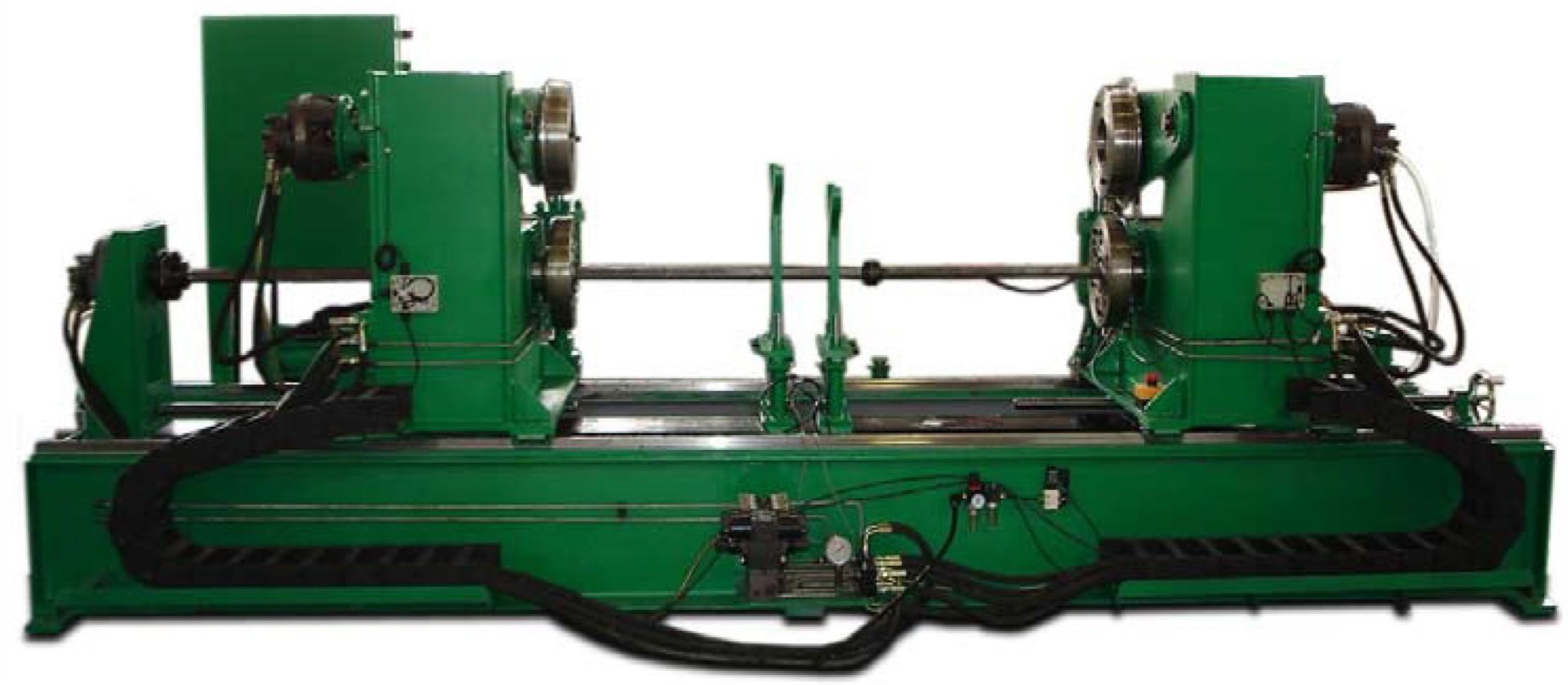

This specially designed machine was developed to serve the tank manufacturing industry. The system is designed to cradle, lift and center the tank assembly in various diameters and length based on the specific product line range.

A touch panel with memory is provided to enable selected values, timing & sequencing to accomplish consistent tubular end forming.

Simple Hard tooling is designed to square and form the required off set joggle or “bell” end desired. Engineered to provide 24/7 opperation requiring very little maintenance.

Video

Gallery

Features

- Heavy duty hydraulic variable piston pump, reservoir, filter for 24/7 operation

- PLC sequence control – Touch Panel

- Automatic part cycle

- Pneumatic cradle lift for tank centering

- Electrical disconnect

- Welded steel construction

- Clamping pressure indicator

- Precision linear bearings

- Quick change over

ADDITIONAL OPTIONS:

- Automatic part ejection

- Tank conveyor

Specifications

N/A

Applications

N/A

Ask our experts about your unique challenge

Previous Product

Heavy Duty Hydraulic Two Sided Automatic End Forming System