Introduction

CHALLENGE

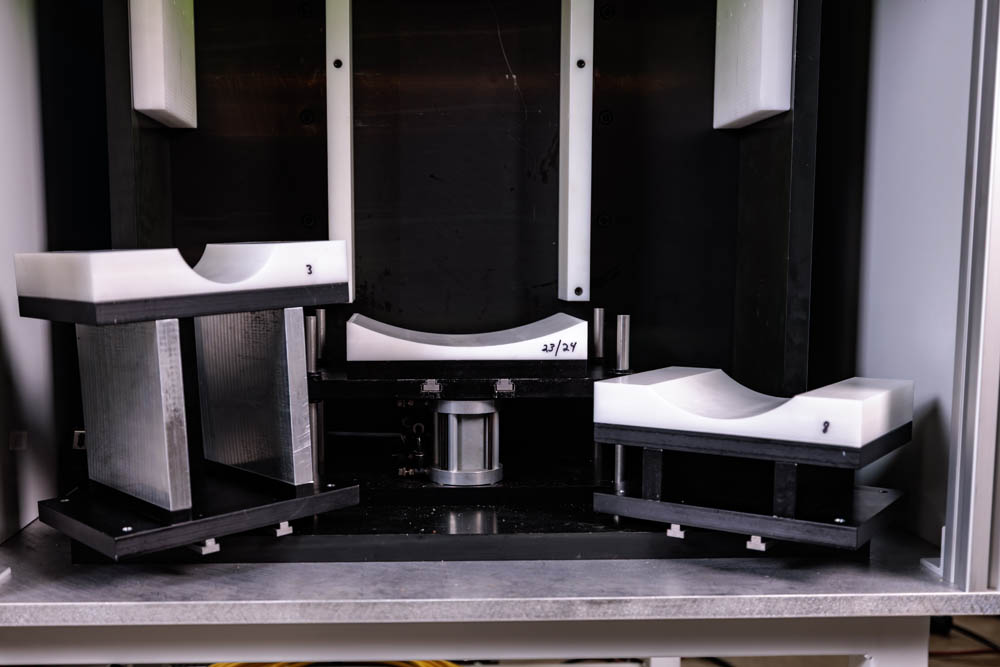

Design an automatic seam welding system capable of handling an extremely wide range of tube diameters from 3″ to 24″ while maintaining the precision required for high-speed laser seam welding. The system needed to consistently present the tube seam in a highly accurate and repeatable position, regardless of size or material.

Additional challenges included developing quick-change tooling to minimize changeover time between diameters, integrating an automatic seam squaring mechanism to ensure tube consistency, and designing a mandrel with specialized clamping to properly manage and stabilize materials during welding. All motions, sensors, and process logic also had to be managed by a single controller to ensure reliable productivity and simplified operation.

SOLUTION

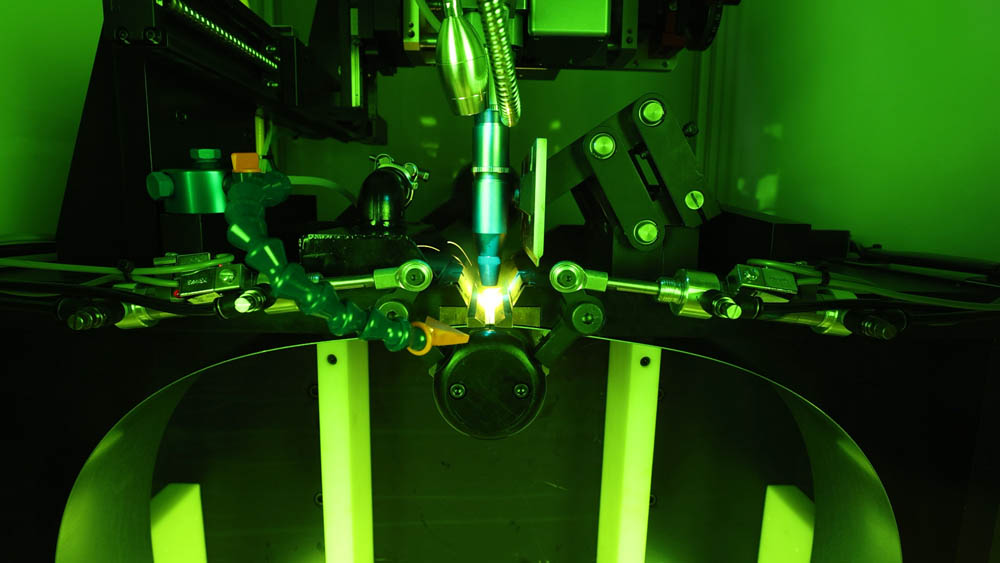

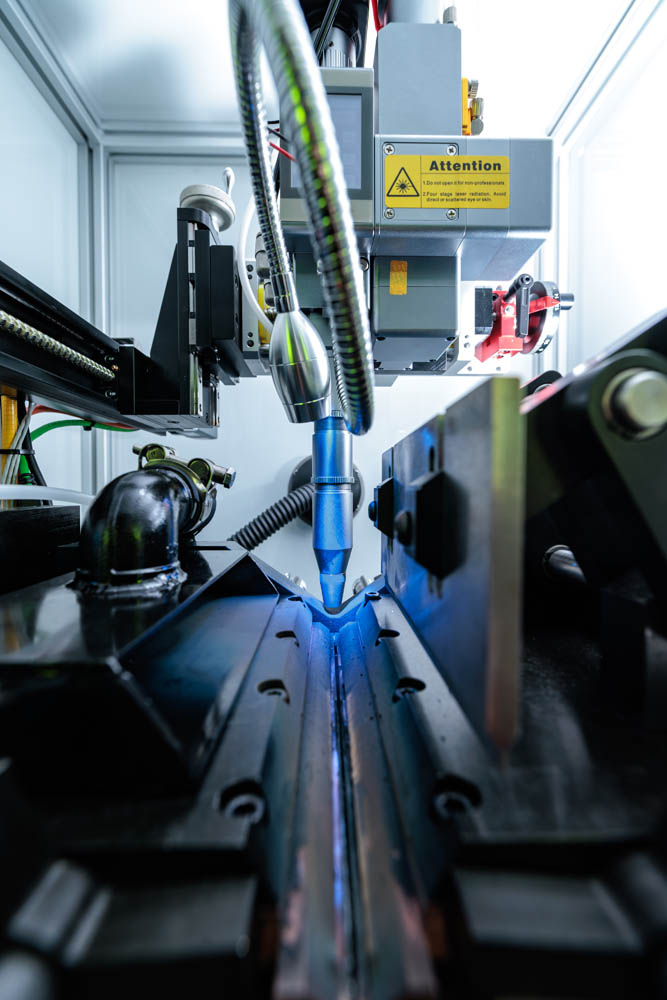

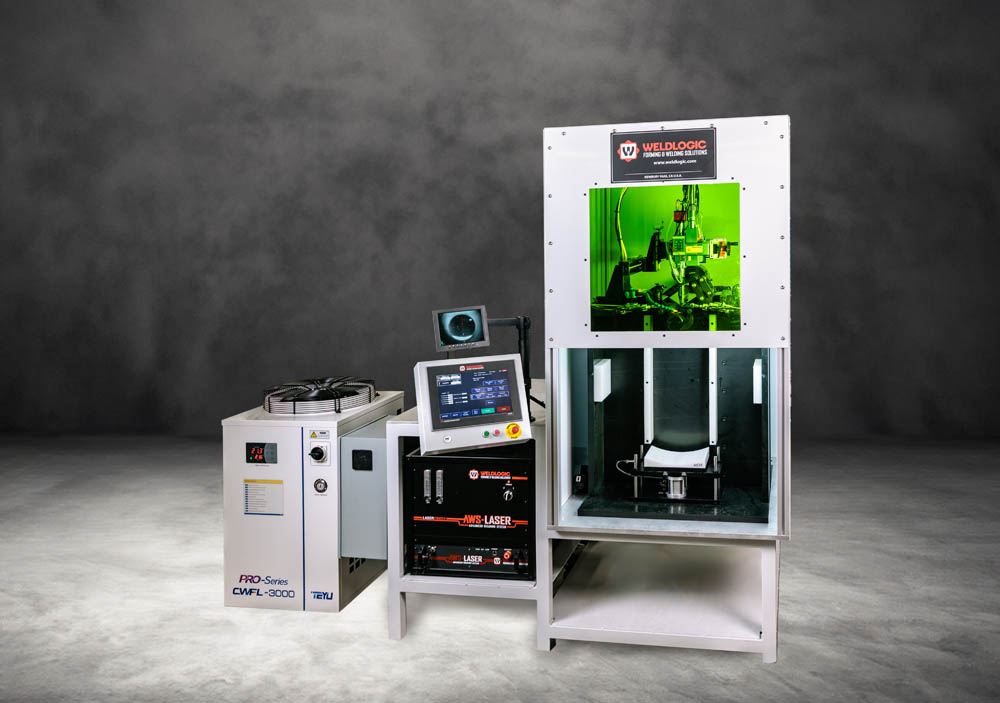

Weldlogic Engineering has 45 years’ experience designing Automatic Seam Welding Systems, and applied that expertise to develop a highly flexible, precision-driven solution capable of welding tubes ranging from 3″ to 24″ in diameter. The system was engineered to accurately locate and present the tube seam for high-speed laser seam welding, ensuring consistent alignment and repeatability across all sizes.

The design incorporates quick-change tooling to significantly reduce changeover time between diameters, along with an automatic seam squaring mechanism that ensures uniform tube geometry prior to welding.

A custom-designed mandrel with specialized material clamping stabilizes the tube throughout the process, while an advanced controller manages all axes of motion, sensors, and safety logic to maximize productivity and ease of operation. The result is a robust, scalable seam welding system built for precision, speed, and long-term manufacturing efficiency.

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A