Introduction

CHALLENGE

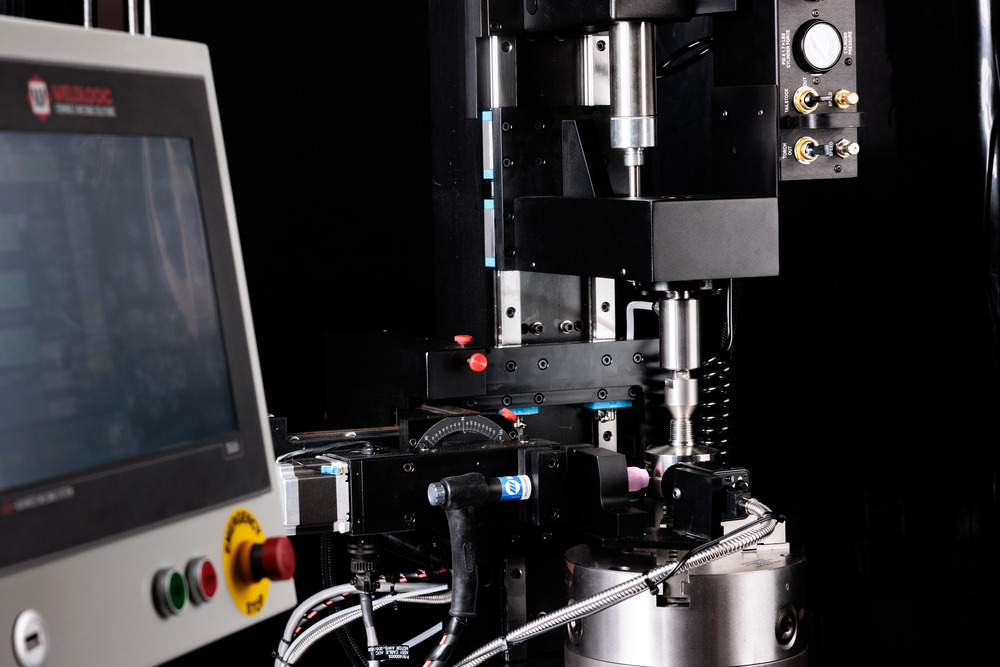

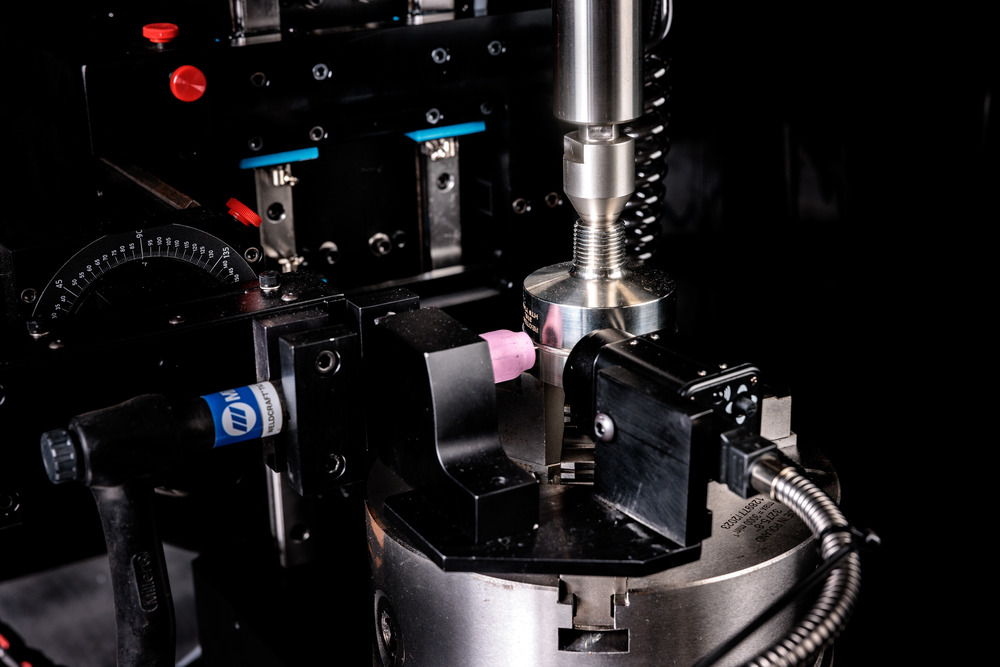

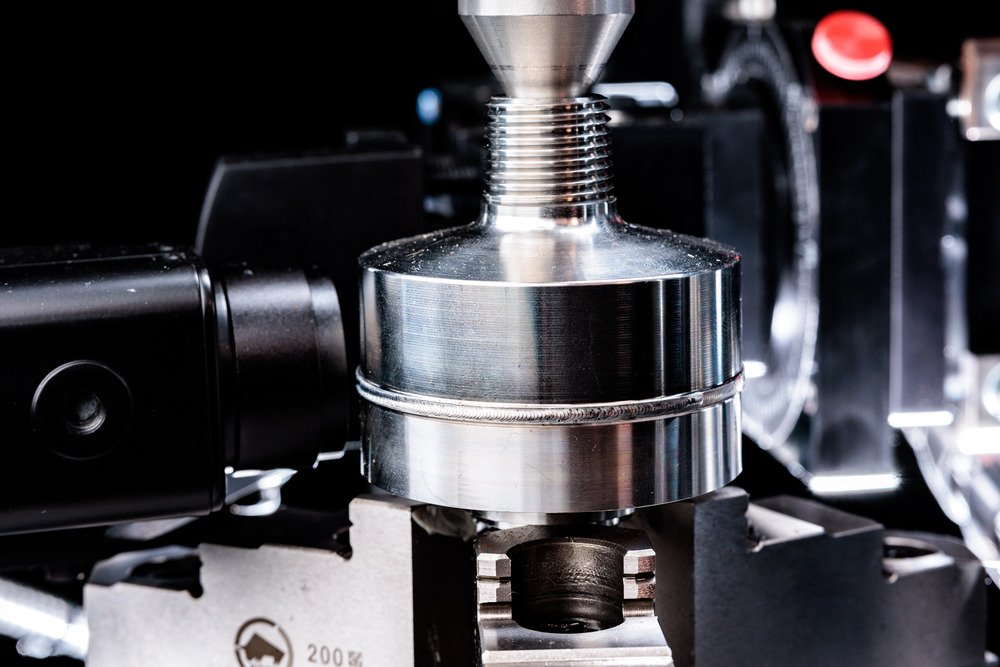

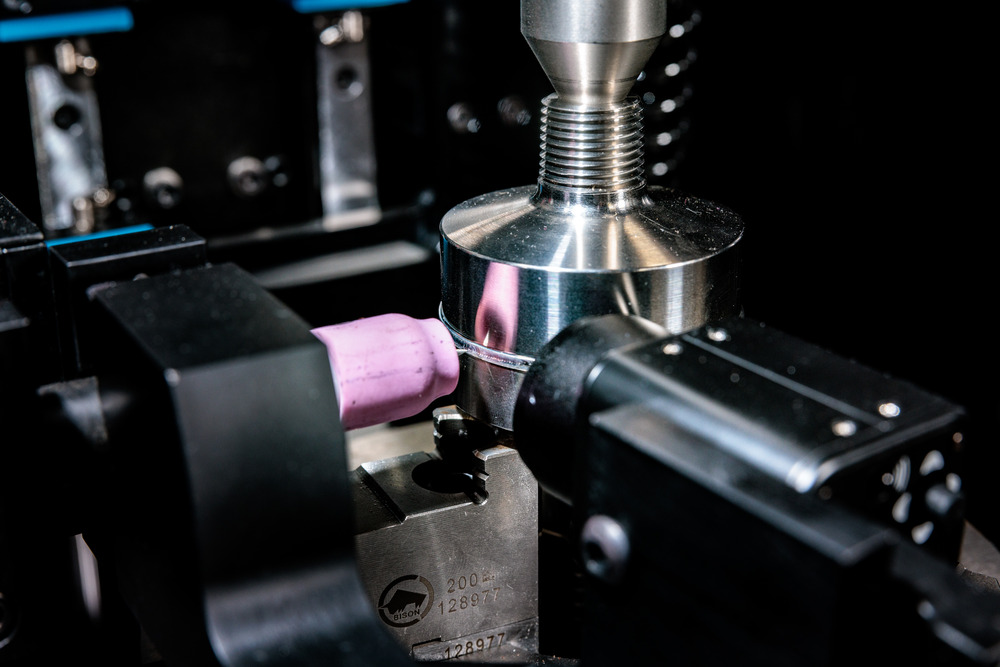

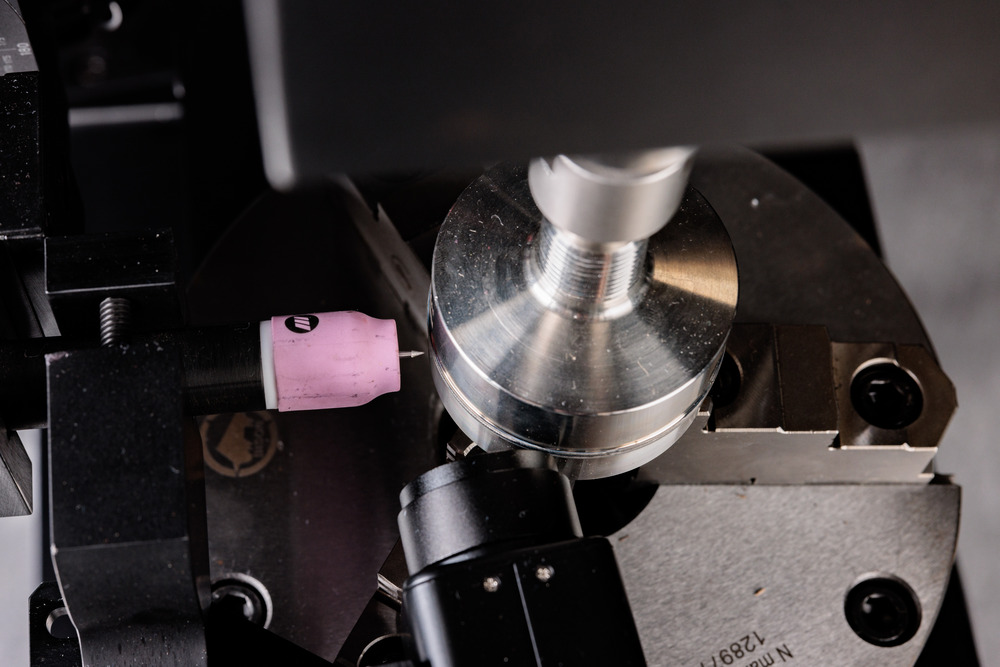

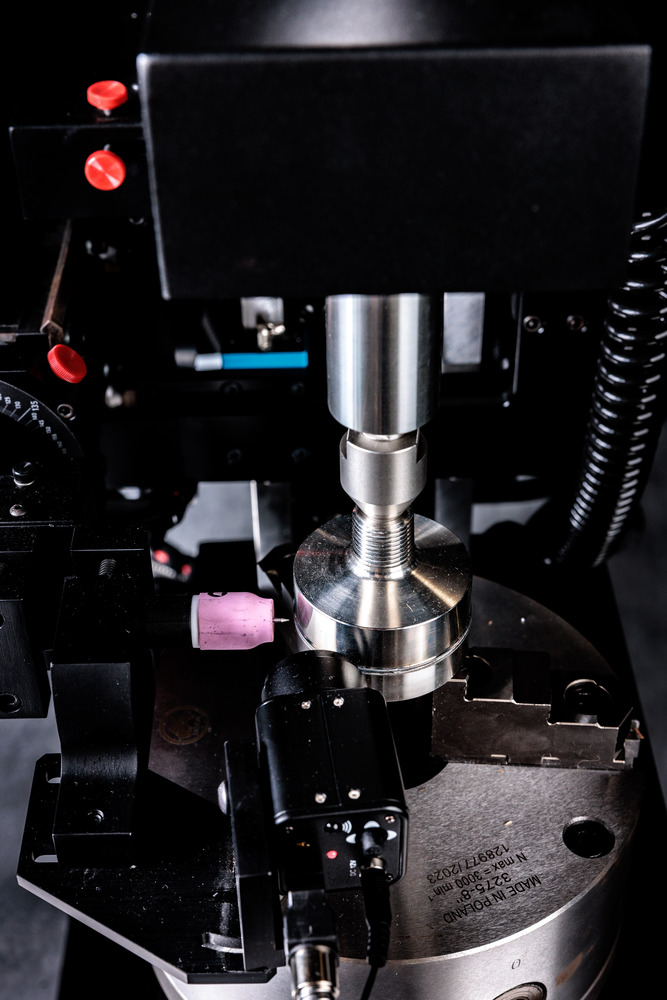

Weldlogic Engineering Team was challenged to develop an Automatic Welding Cell that would offer a repeatability factor of better than 1% of programmed values, the cell had to be fool proof to enable an unskilled operator to make the highest quality GTAW welds with a very compact footprint of less than 40” x 42”. Placing the welding electrode directly over the weld joint was also a variable the customer wanted a solution. Finally, the weld had to produce a very low heat input hermetic helium leak tight seal weld on this high reliability product.

SOLUTION

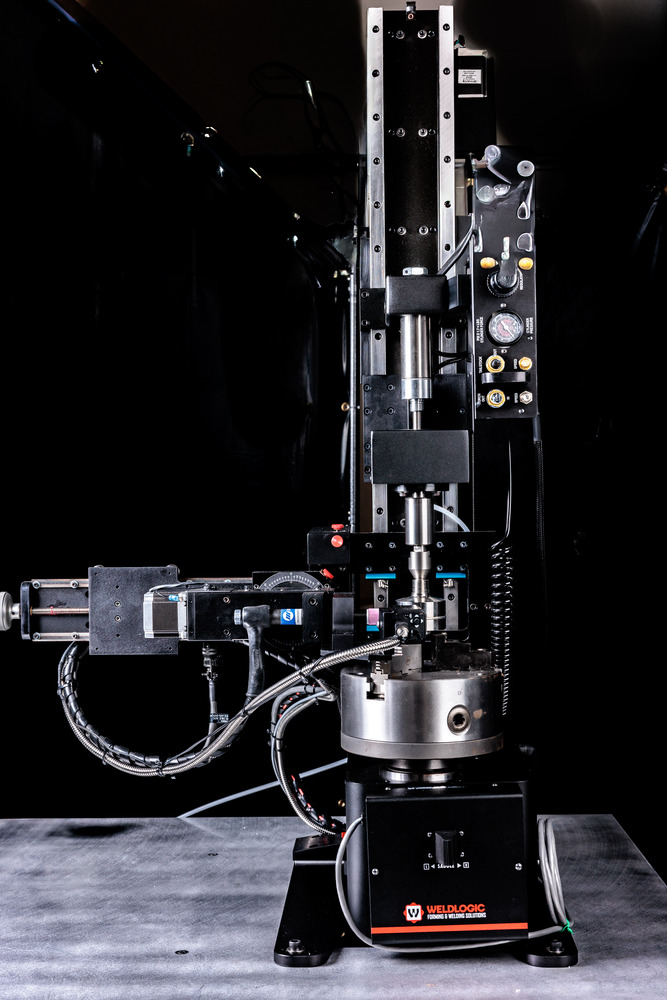

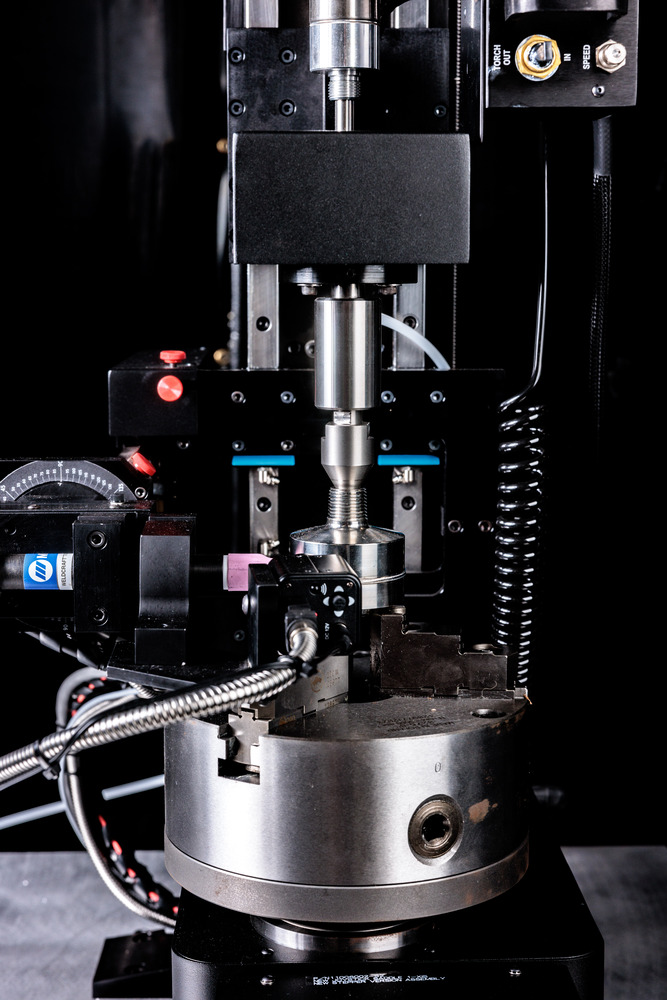

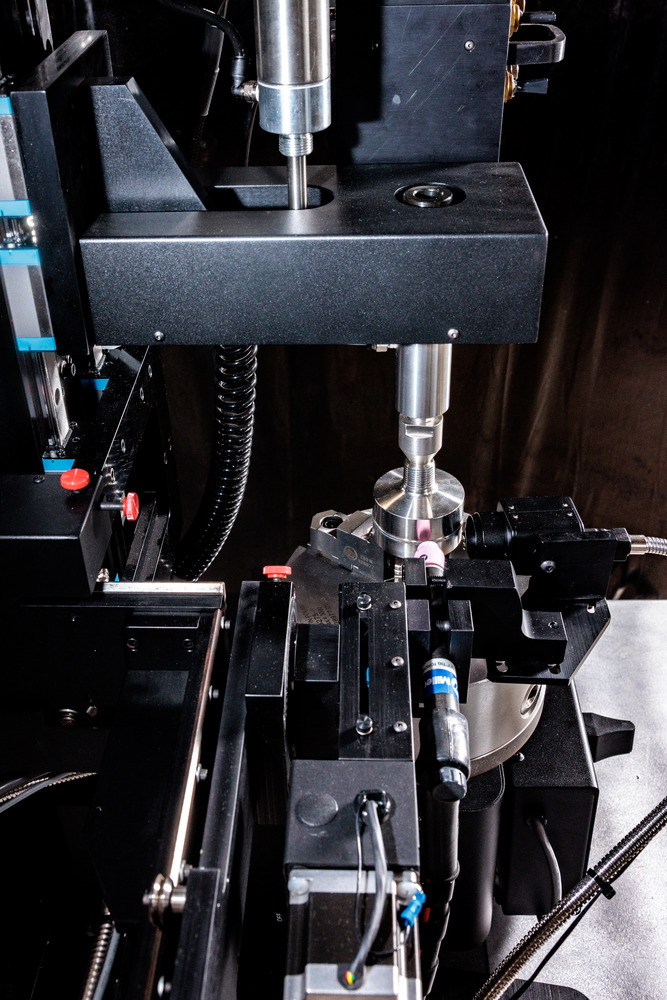

Weldlogic Engineering met all the customers’ requirements with a Compact Vertical Workstation topped with a sturdy Aluminum Tool plate by which the PWL-15-36 Lathe was securely mounted.

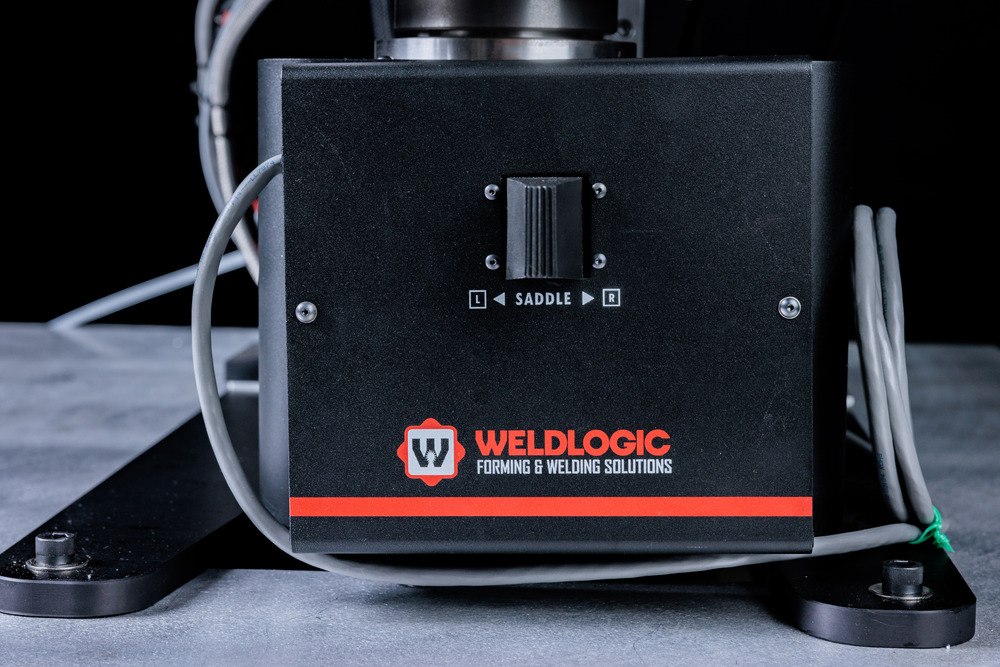

The workstation table housed the Advanced Welding System A.W.S. 210 power supply and controller that uses all A.C. Servo drives and motors to deliver better than 1% repeatability.

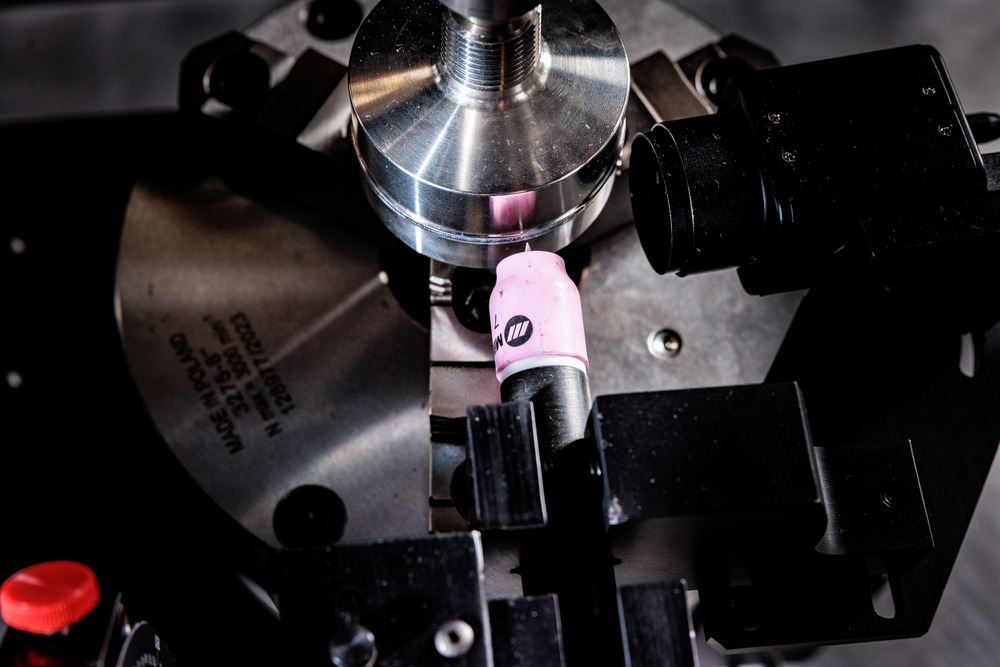

The Weldlogic Arc Distance Control set the programmable precision Tungsten to work gap before every weld and a Hi-Def camera and color monitor was provided to enable easy electrode placement over the circumferential seam weld.

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A