Introduction

CHALLENGE

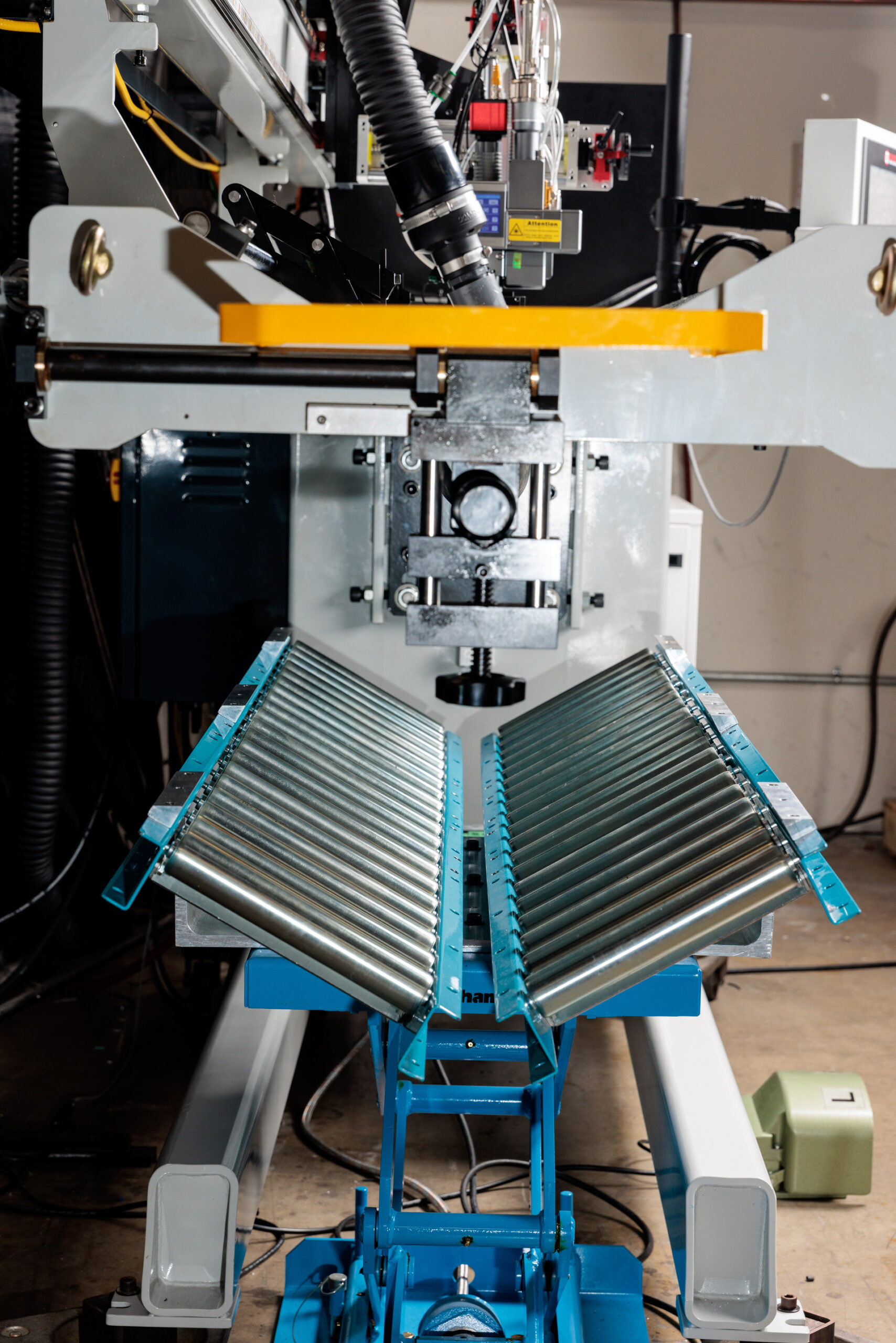

Design a seam welder that can efficiently weld a wide range of diameters, tube lengths, in a variety of thicknesses & alloy. The seam welder needs make strong seam welds in S.S., Galvanized, C.S., & Aluminum. A Do-All seam welder that doesn’t require a specialized welder to make acceptable results. The system needs to store all the programs for quick recall, repat results better than 1% and weld at speeds exceeding 100 I.P.M.

SOLUTION

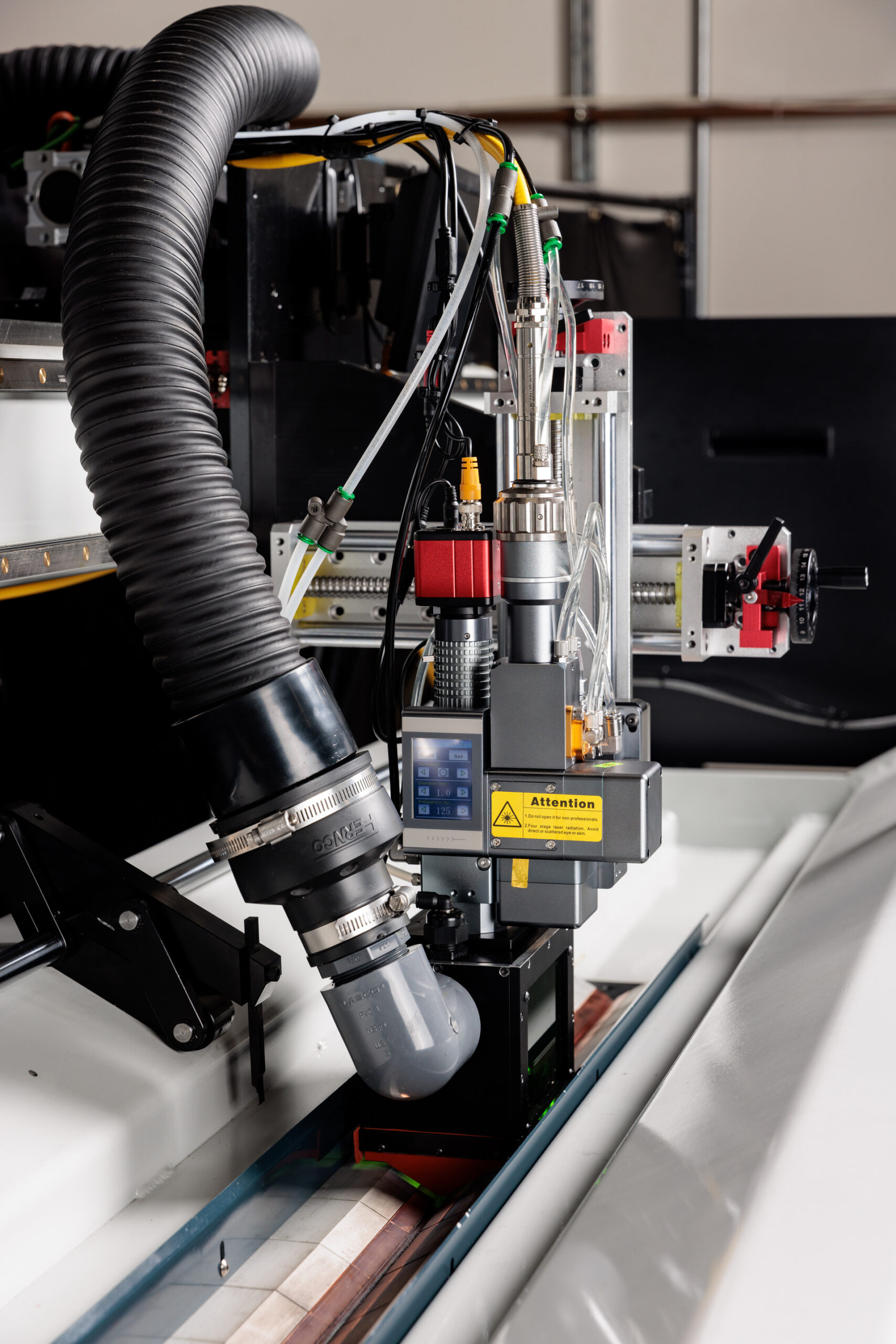

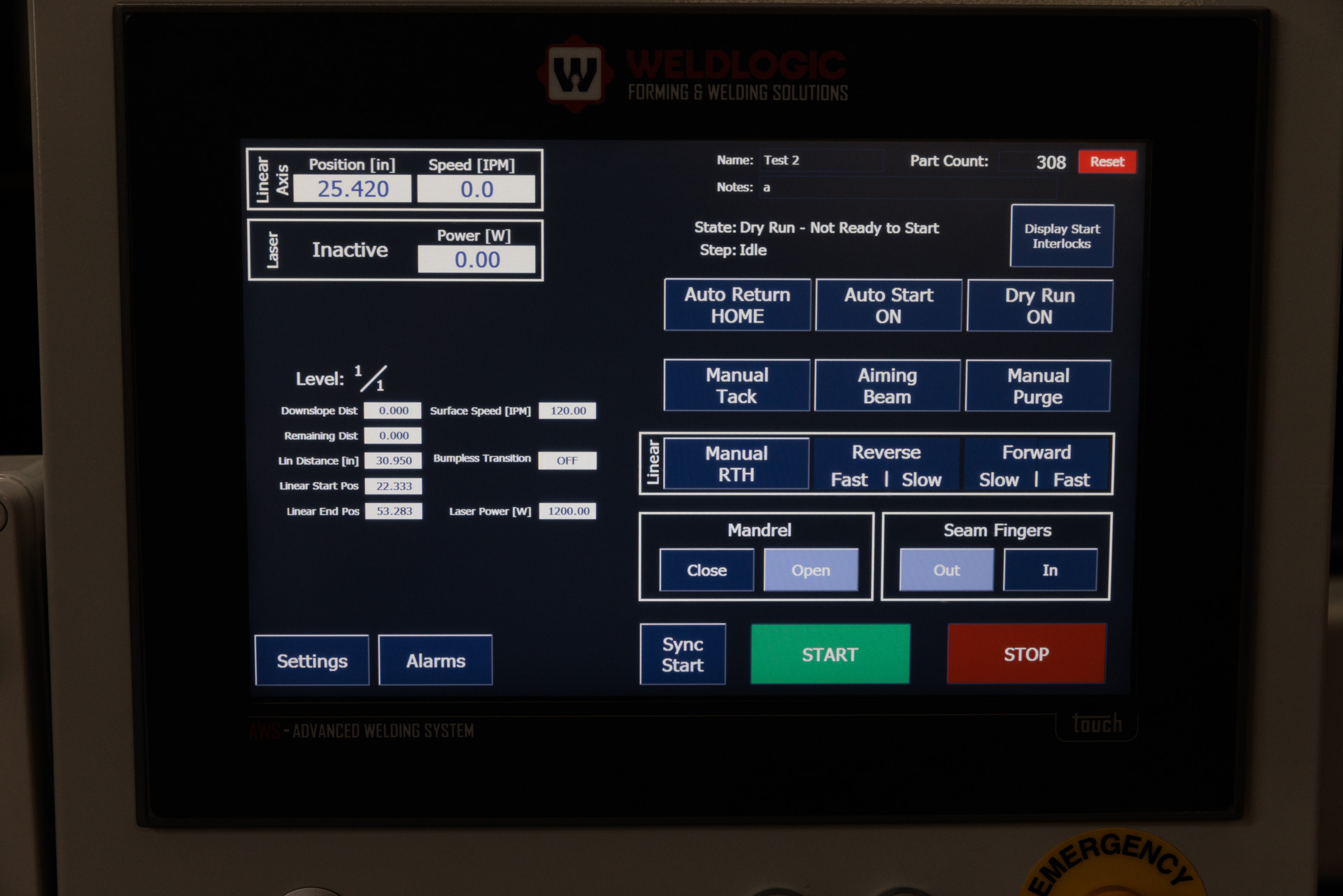

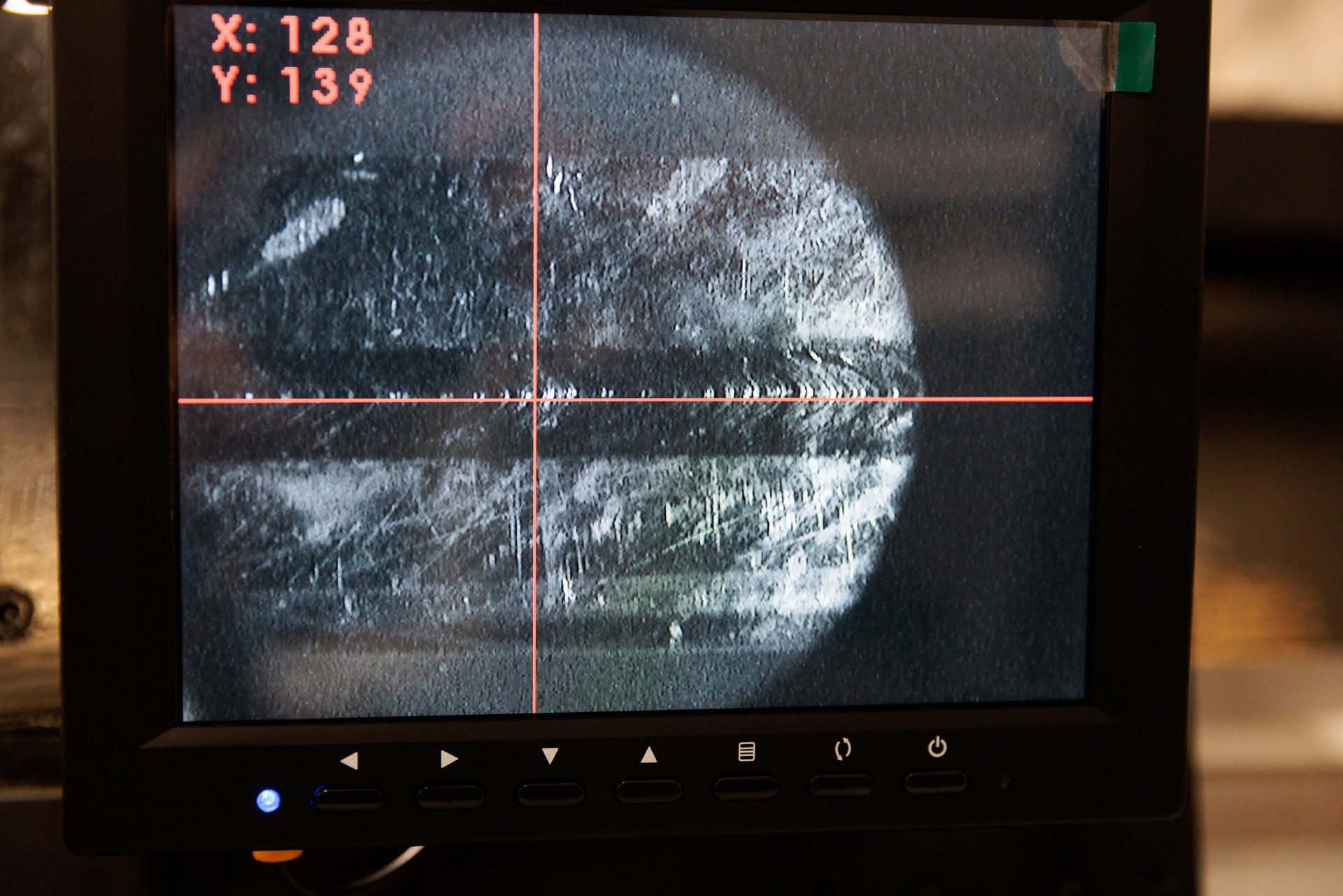

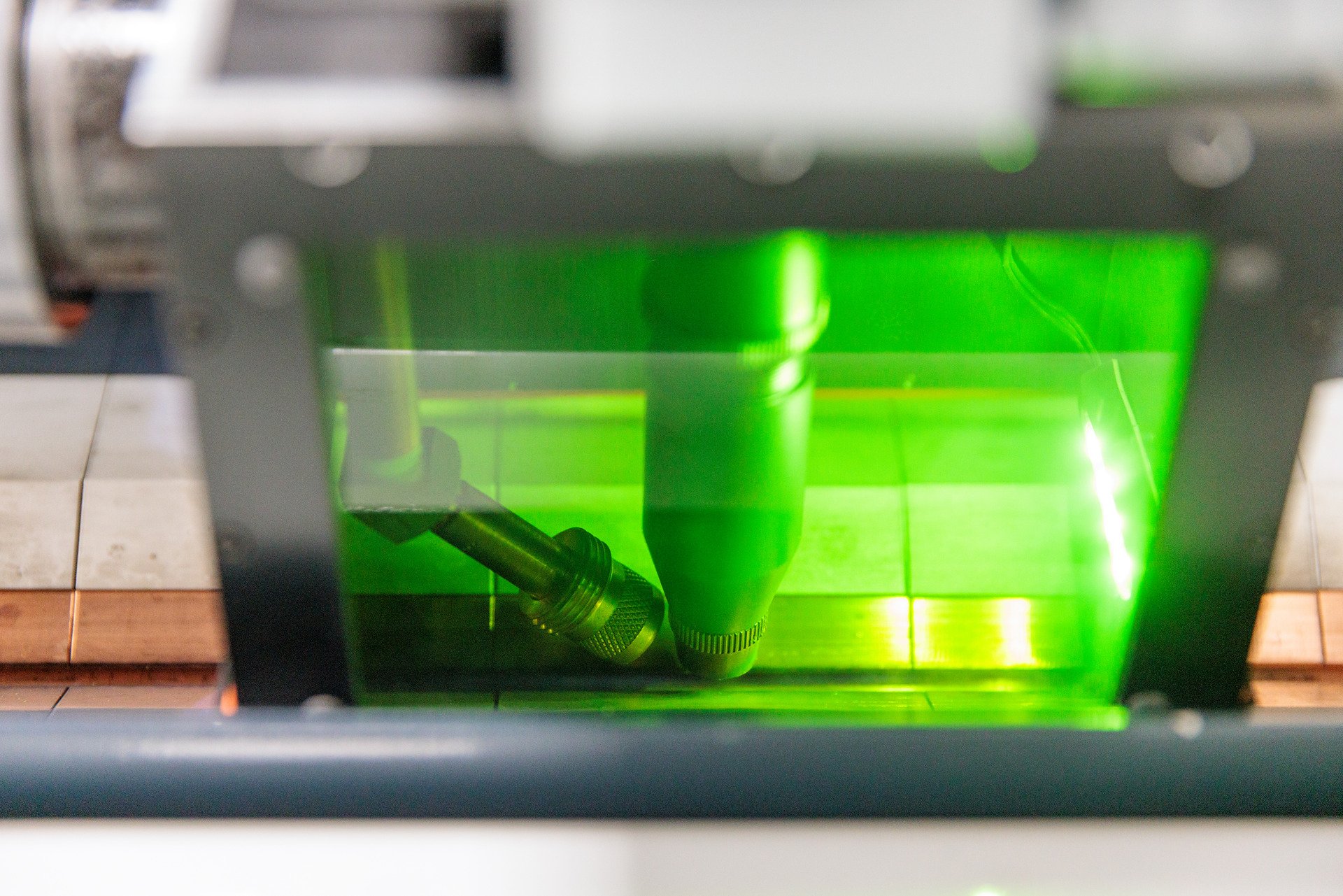

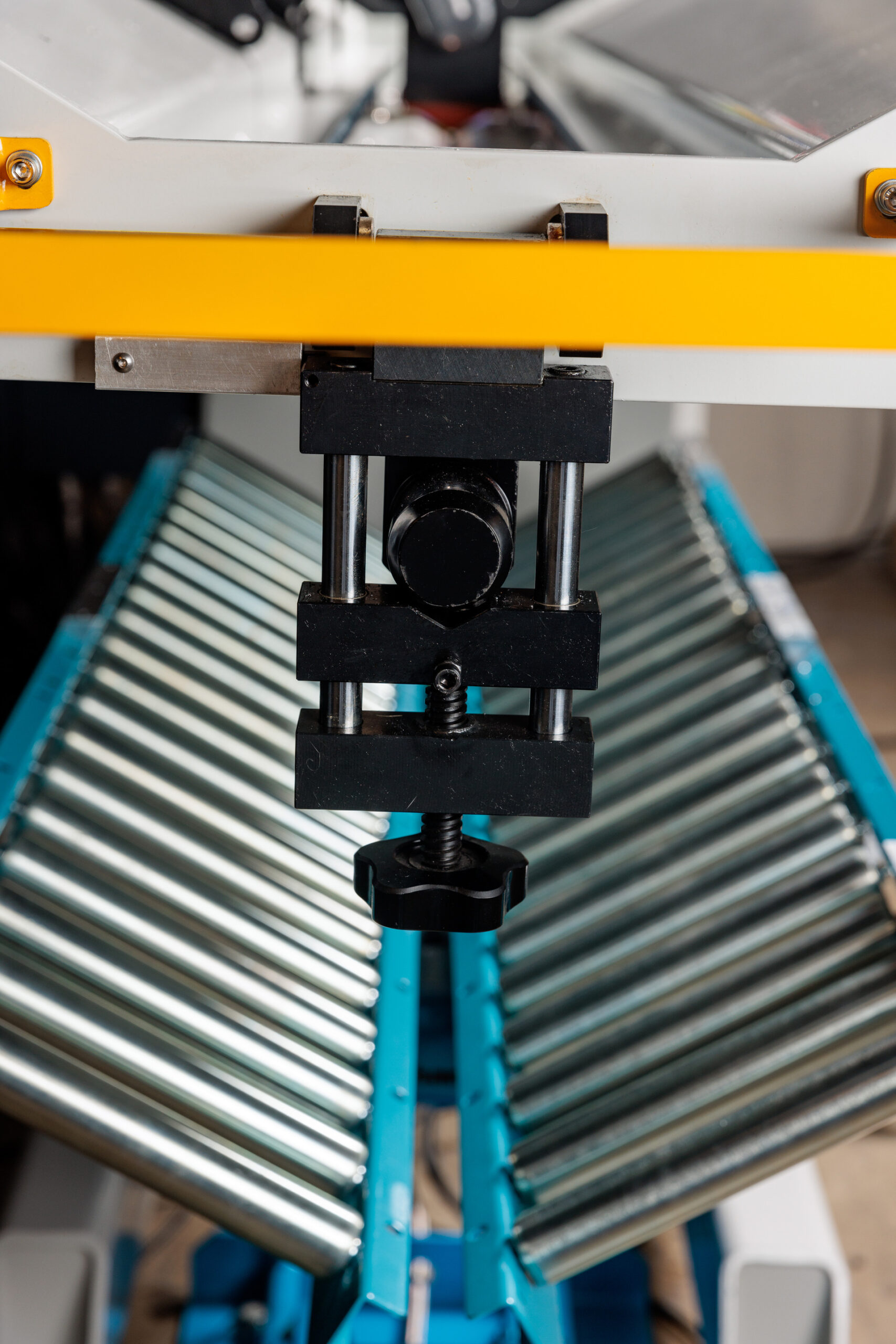

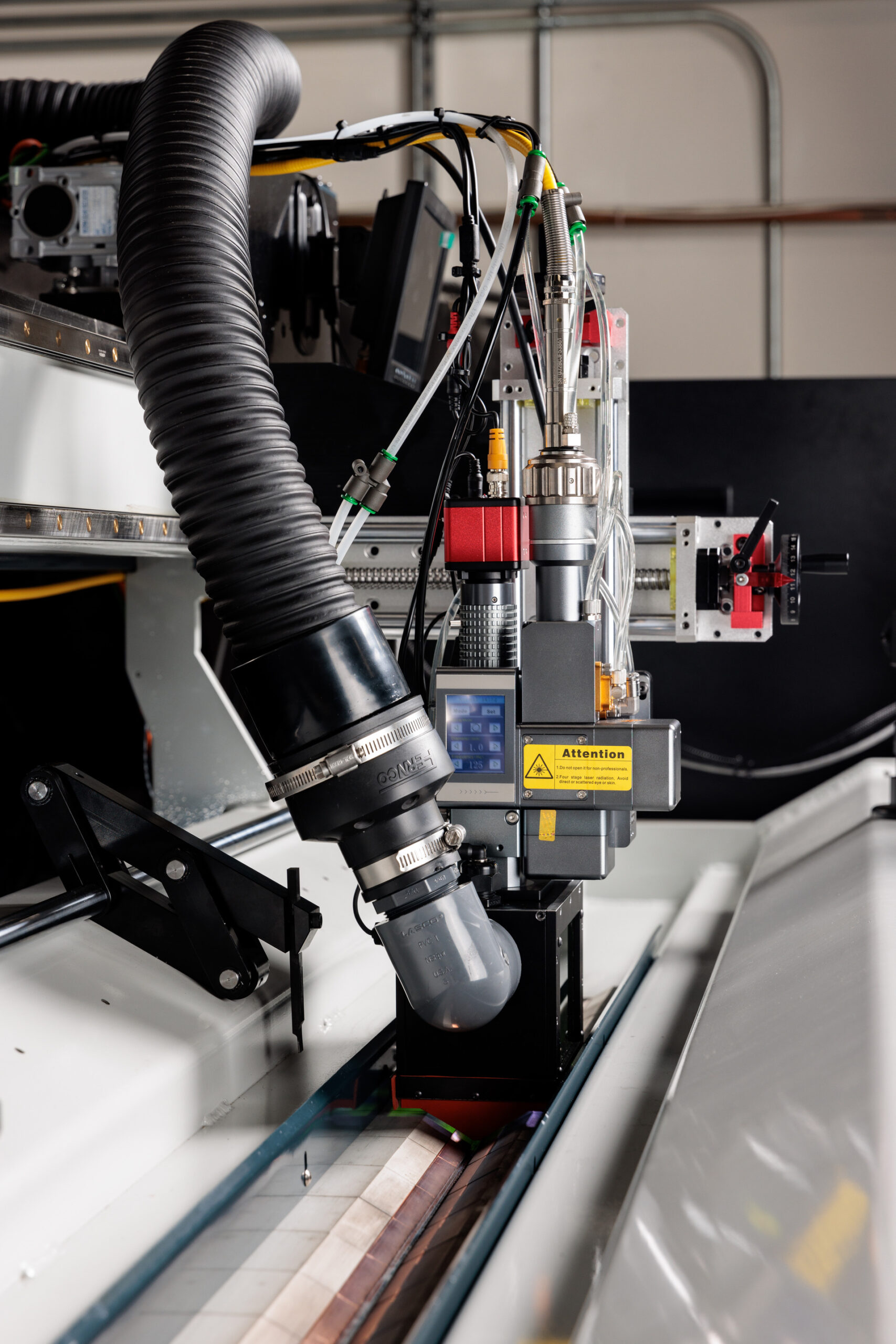

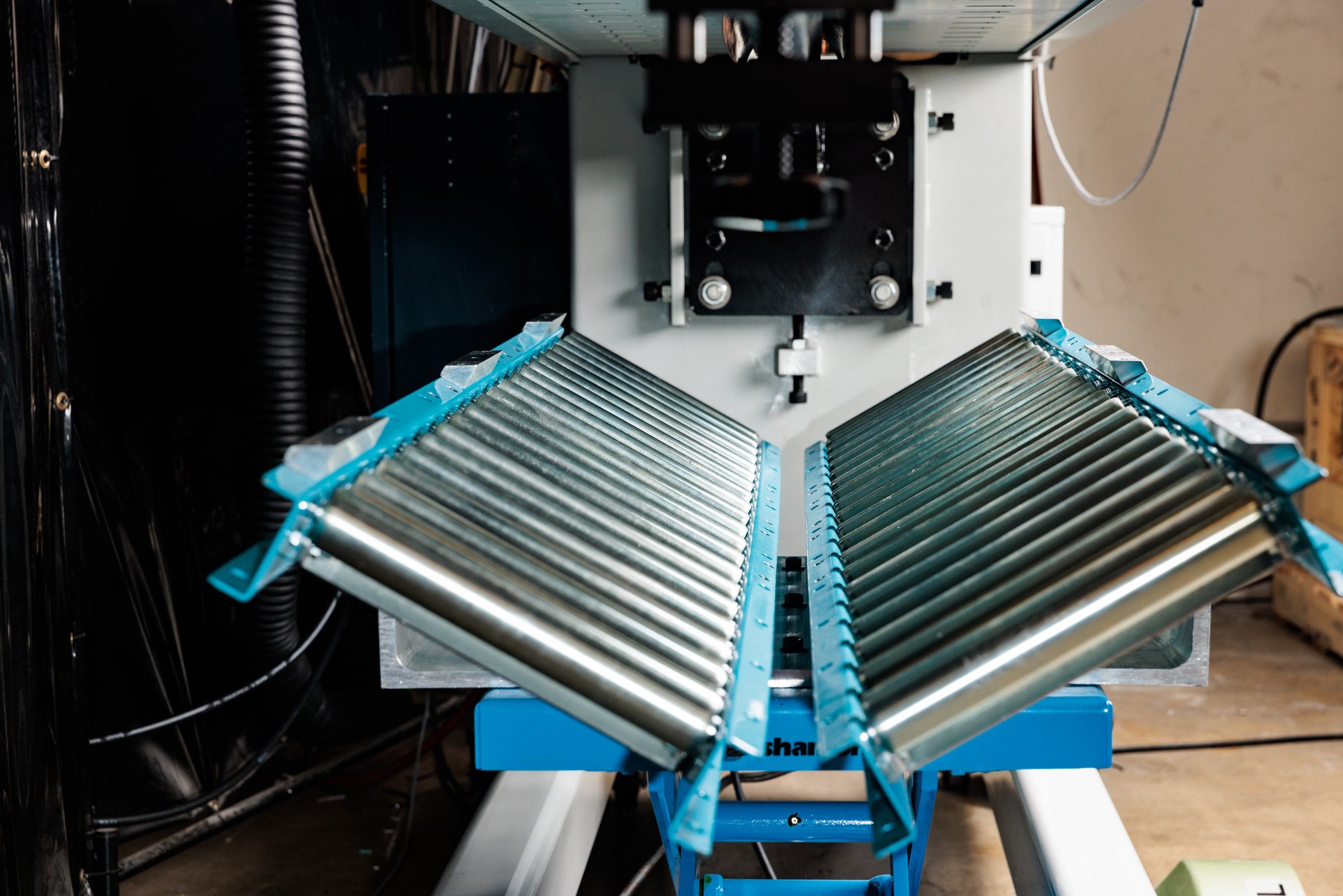

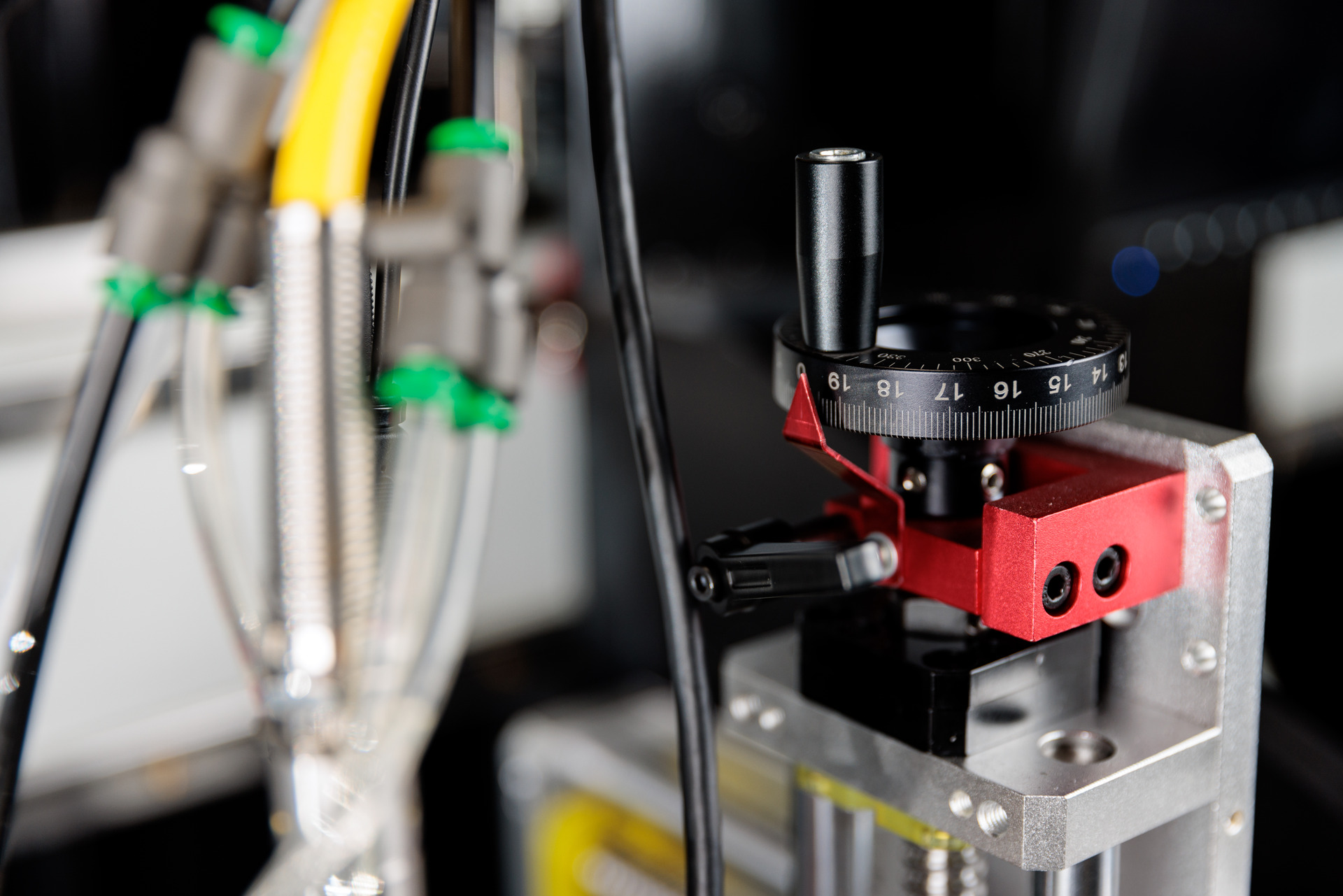

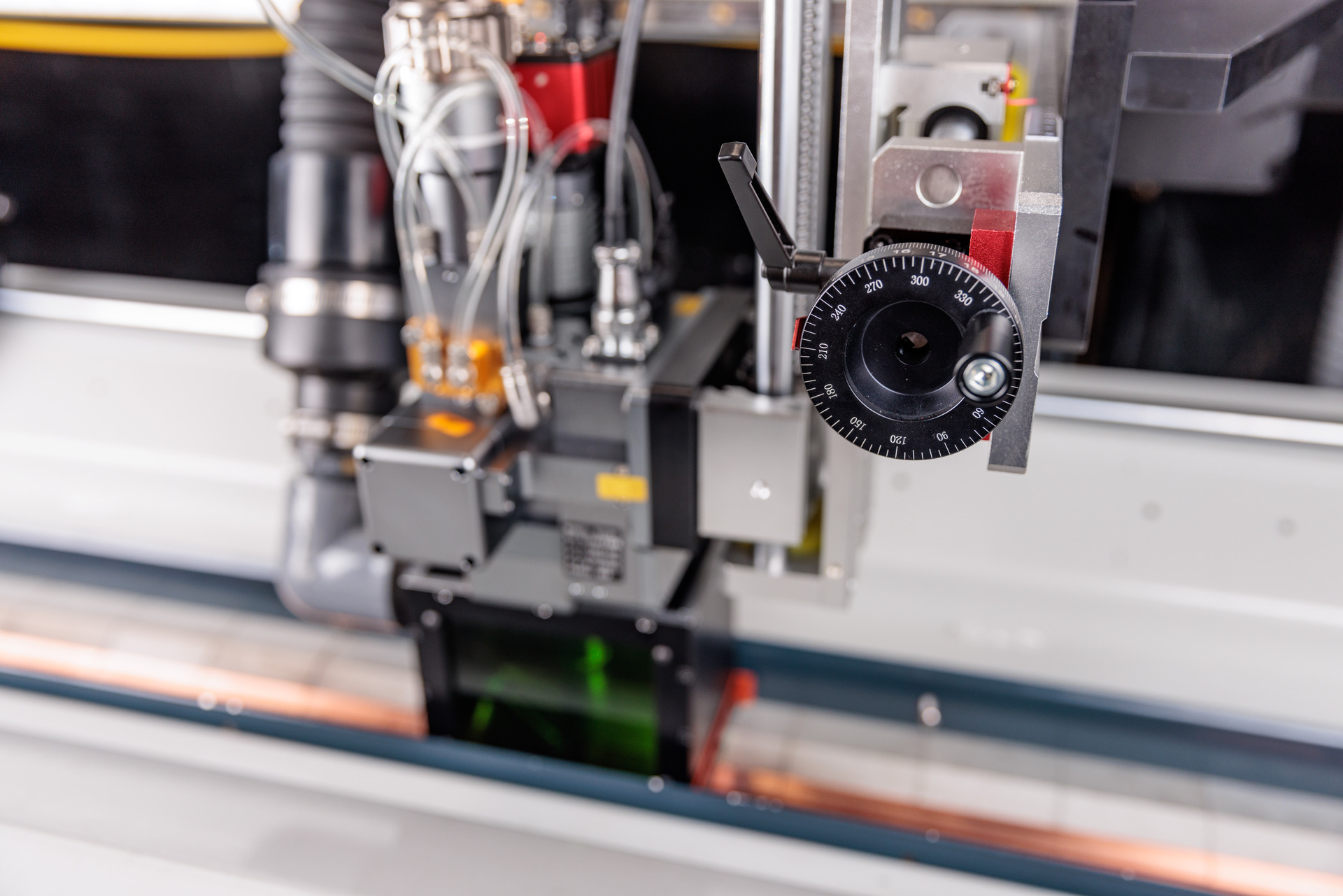

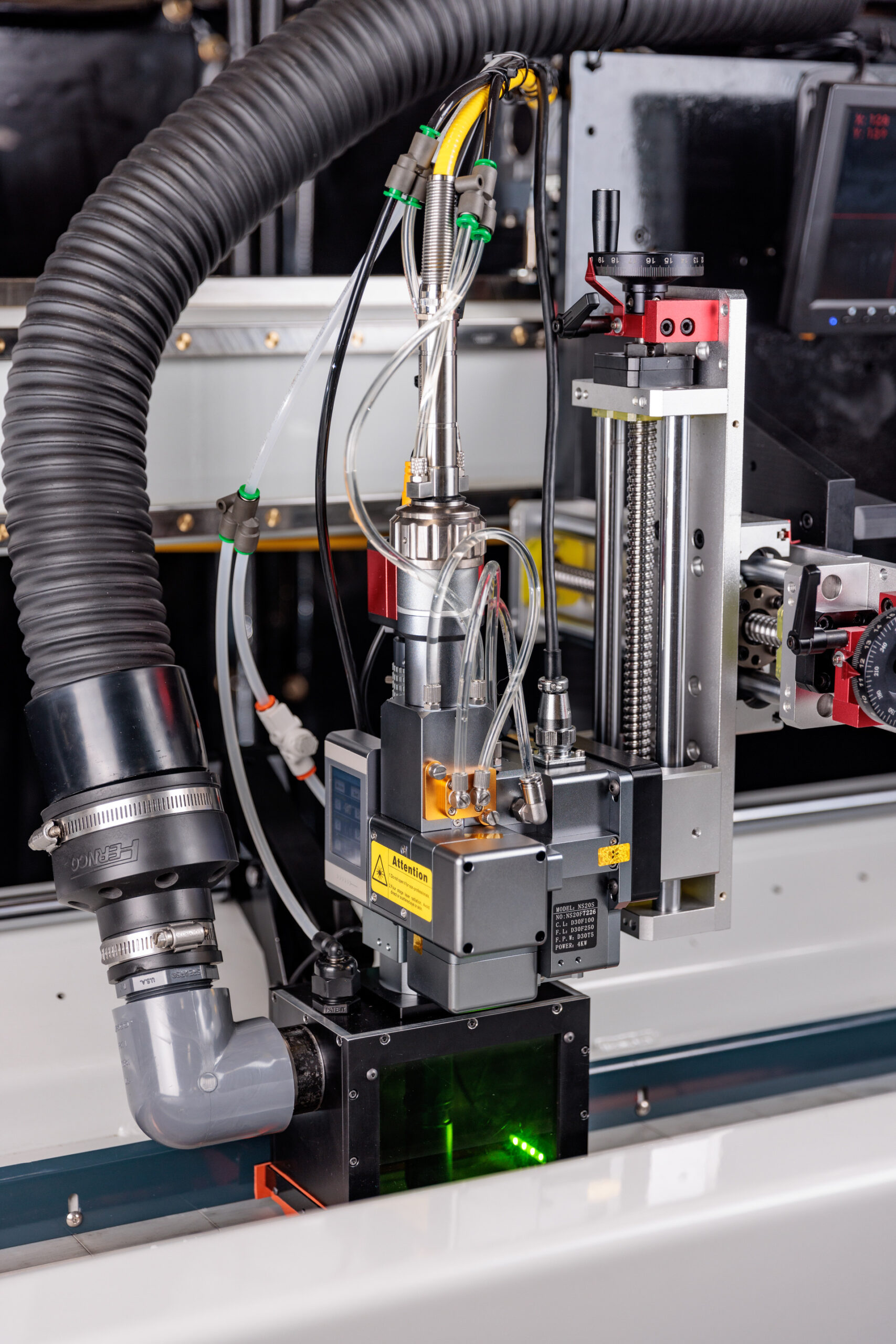

Weldlogic Engineering selected our PLS- Precision Longitudinal Seam Welder platform and designed a cell to enable the end user to laser weld the full range of diameter, lengths, thicknesses, and alloys. The system included an optional wire feeder to enable welding Aluminum ducting. The AWS Advanced Welding System controller was selected to manage the entire process and 2000 Watt Laser with Wobble head. Extra foot pedals were provided, and remote start stop was provided at the customer’s request. The laser was fully enclosed to contain the laser and smoke generated from the welding process and processed thru a hepa filter.

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A