Introduction

CHALLENGE

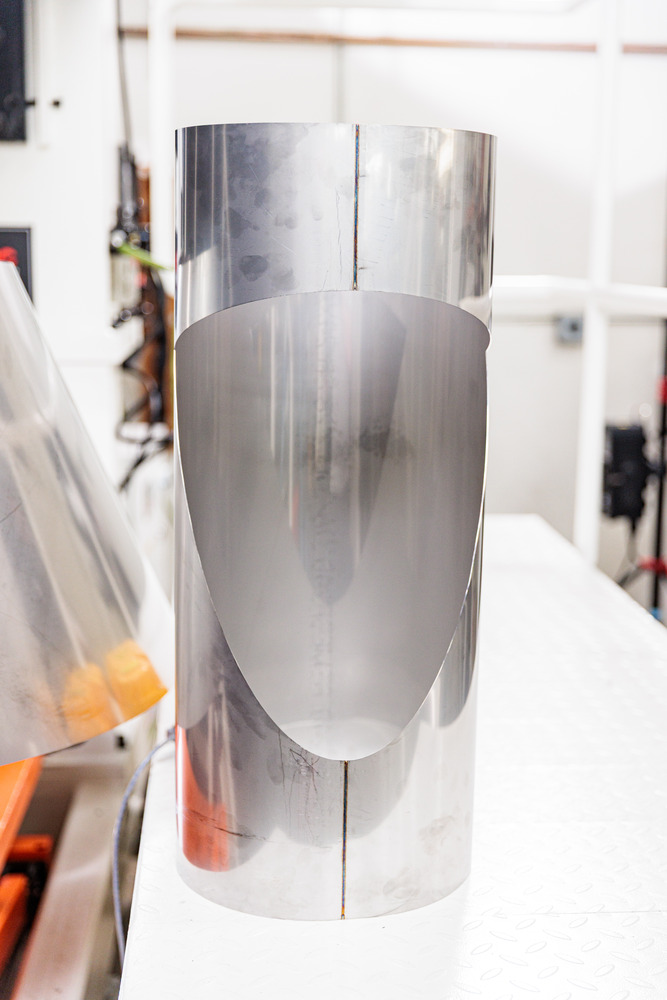

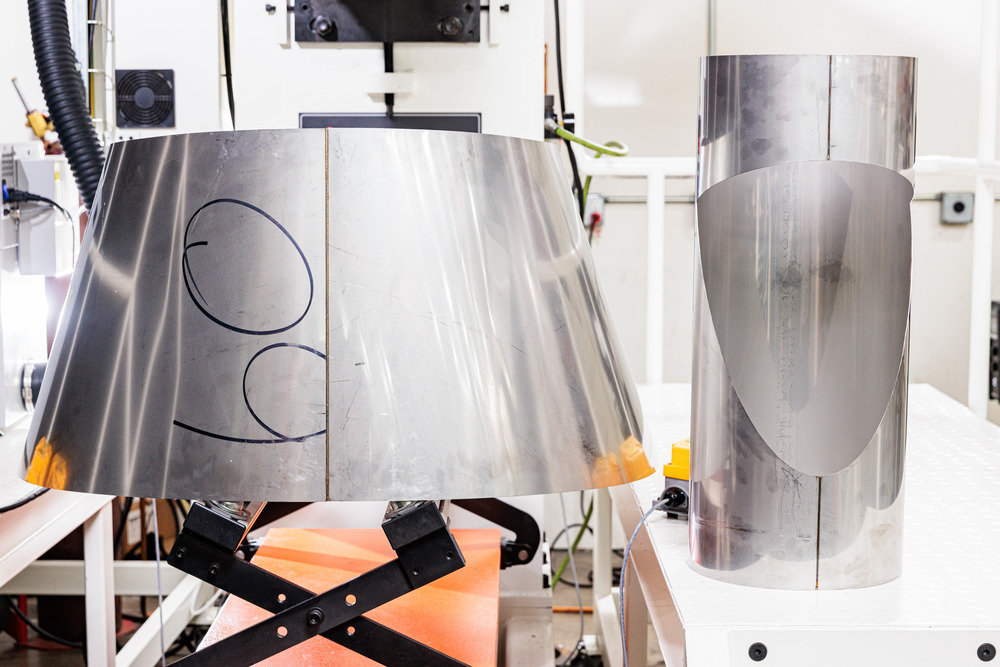

Design and Build an Automatic Laser Seam Welder that enables butt Seam Welding a wide range of materials that include, Galvanized, G-90, 316-S.S., 304-S.S., & Aluminum.

The manufacture needed capacity to weld a wide range of diameters 5” – 65” and a variety of lengths depending on orders placed that week.

The Laser Seam Welder needed to be very flexible to accommodate wide range of shapes, and future undefined applications.

SOLUTION

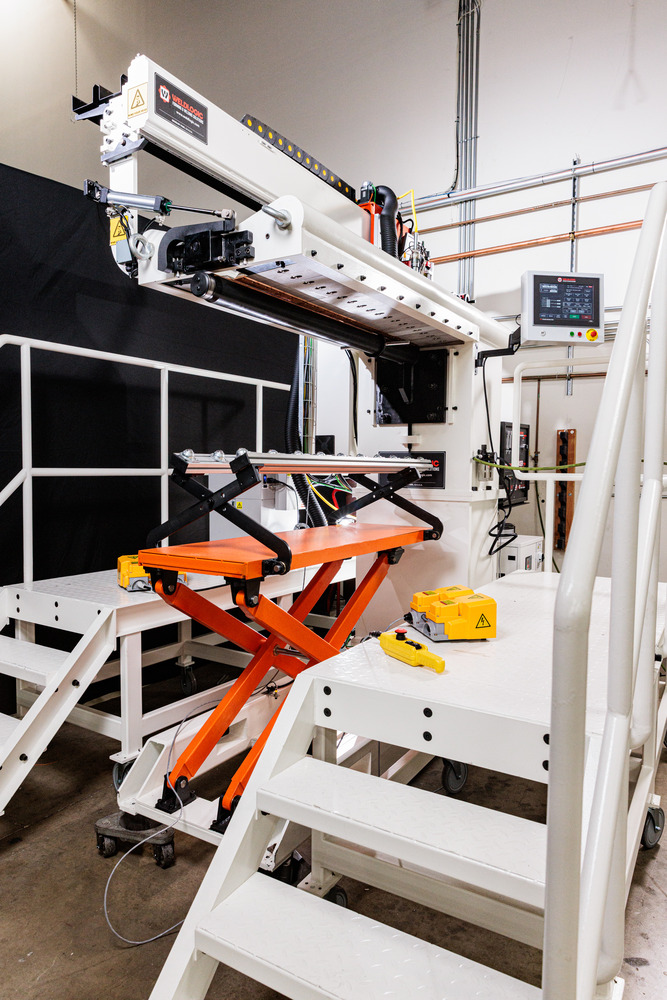

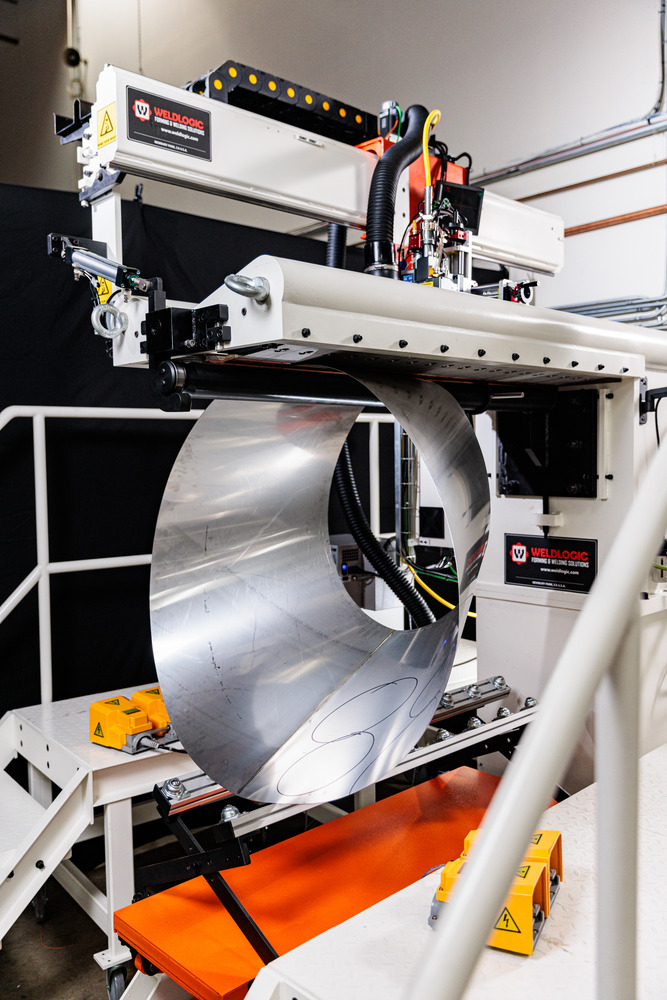

Weldlogic Engineering selected our PLS Precision Longitudinal Seam Welder and added a riser to enable the Laser Cell to accommodate diameters from 5”-65”. To enable the operator easy system management, they provided two catwalks to manage the seam welder from either side.

To support the larger diameters a powered elevating load and unload scissor lift was provided. Engineering integrated our AWS-Advanced Welding System controller to manage the high-speed A.C.Servo driven carriage, laser, gases & chiller.

Our Warthog tm Laser process software was used to manage and store all the seam weld programs.

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A