Introduction

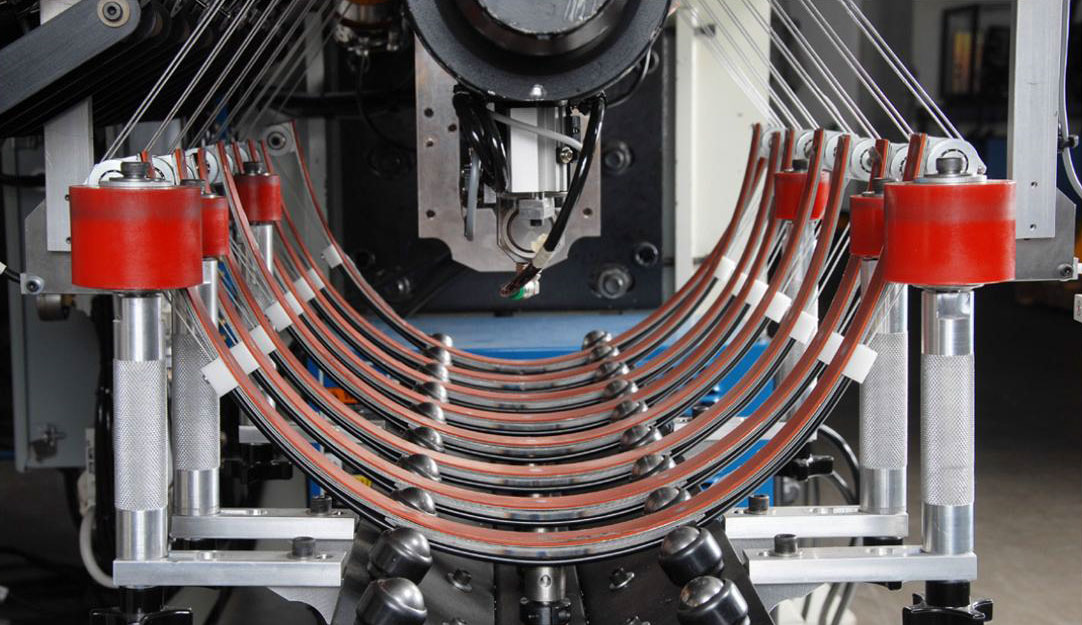

Weldlogic Engineering were tasked to design and manufacture a high production dual plasma torch seam welder to enable a low skilled operator to run both our automatic roller and automatic seam welder.

The vessels were thin walled .030” (0.76mm), with diameters from 11.00” (279mm) up to 13.75” (349mm), and lengths to 28.375” (720mm).

Video

Gallery

Features

- Suitable for TIG, Plasma, MIG, Sub-Arc and Laser welding

- Fully welded fabrication

- Mandrel has vertical adjustment for various thicknesses

- Adjustable mandrel latch with unique safety control

- Independent left and right finger clamping

- Precision ball bearing, linear track for smooth travel

- Standard flexible track to support hoses and cables

- Unique, easy-to-use, precision alignment gauges

- Advanced carriage controls with automatic sequencing

- Pneumatic torch retraction

- Weld process development & support

- Dual pressure control

Dual Torches we chosen to double the weld speeds and produce a higher “Parts Per Hour” production rate to reduce manufacturing costs. High weld quality and production rates were both required for the post weld forming stresses that a full penetration plasma weld could provide and to meet the commercial price point.

A Weldlogic standard PLS-48 Precision Longitudinal Seam welder was chosen as the base system and a Weldlogic “Advanced Seam Welder Control” was selected to manage the special designed automation and part handling. Production rates of over 75 parts per hour were achieved with only one operator to manage materials, rolling the vessels and feeding and unloading the automatic seam welder.

Specifications

N/A

Applications

- Electric motor cases

- Filter elements

- Automotive exhaust

- Nuclear vessels

- Vacuum components

- Cryogenic vessels

- Water tanks

- Aircraft components

- Coring drills

- Flexible metal hose