Introduction

Challenge:

Design and build a C.N.C. welding cell to enable a low skill “operator” to make 600 full penetration low distortion welds per hour.

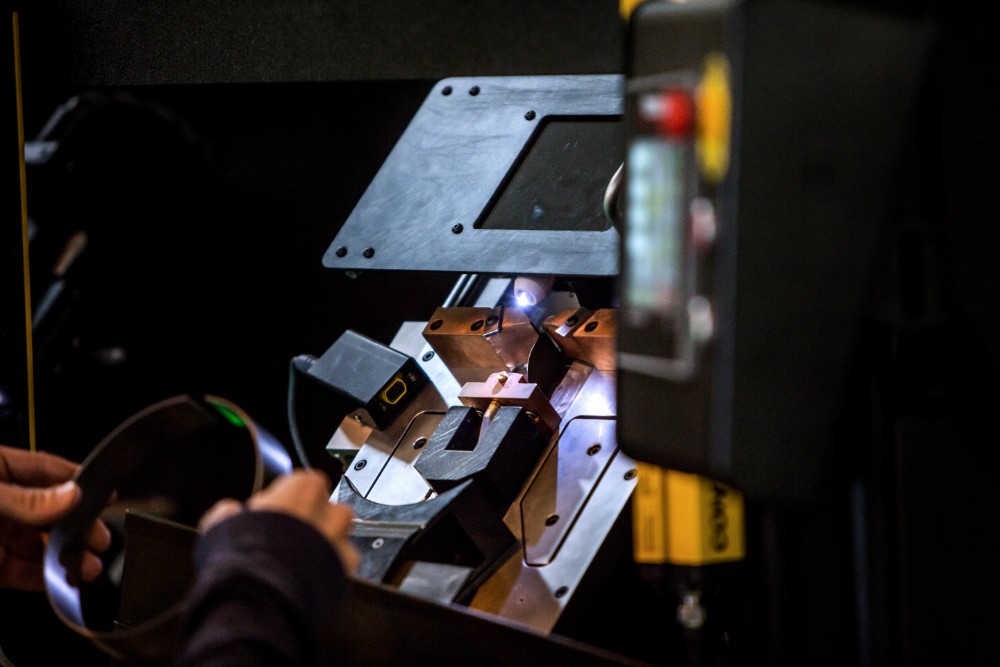

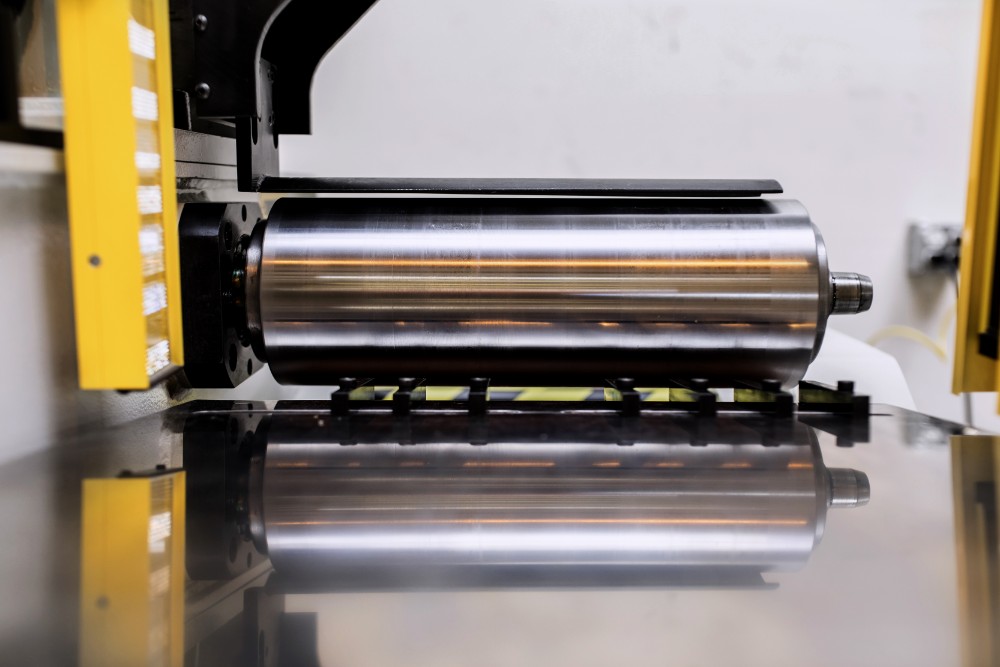

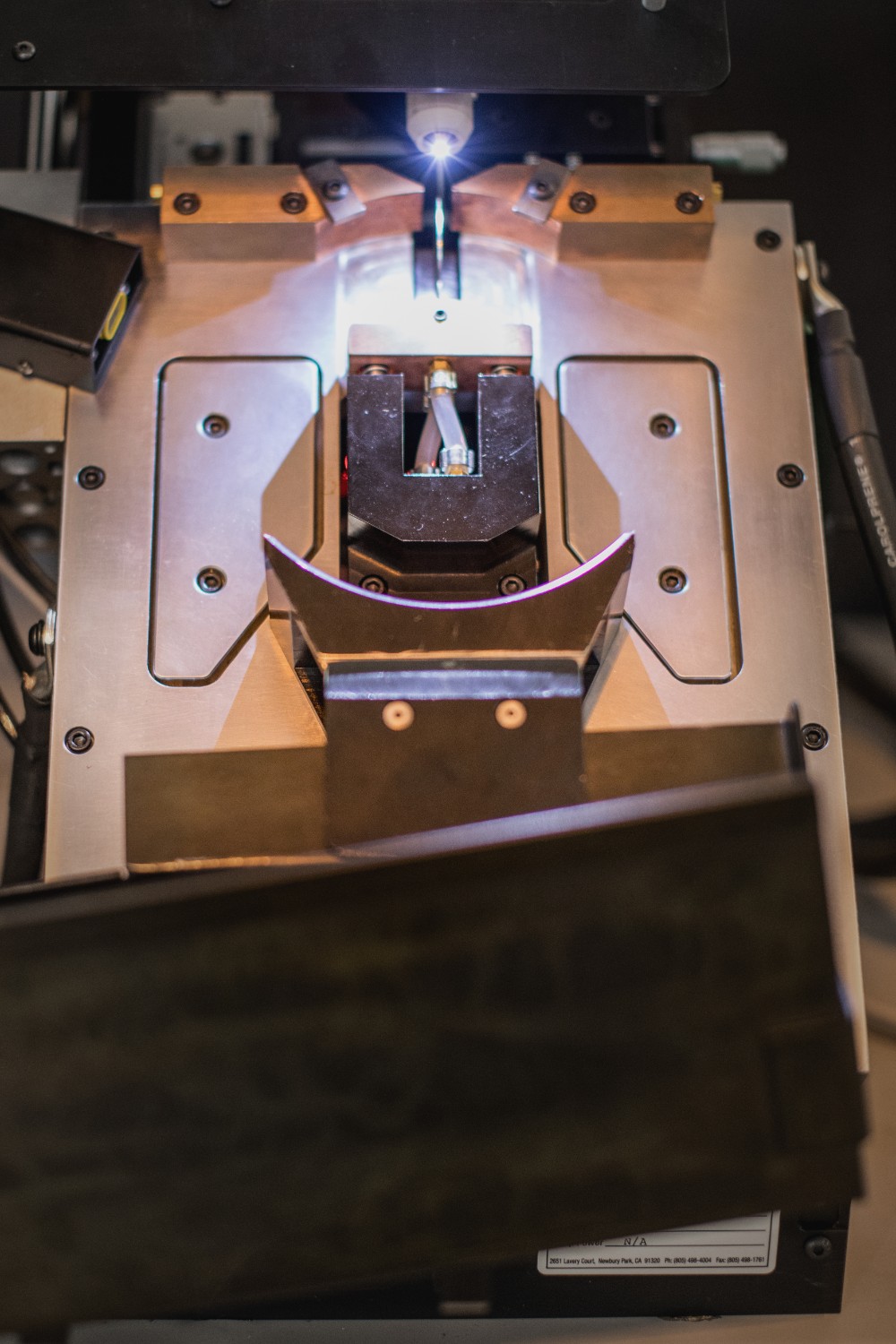

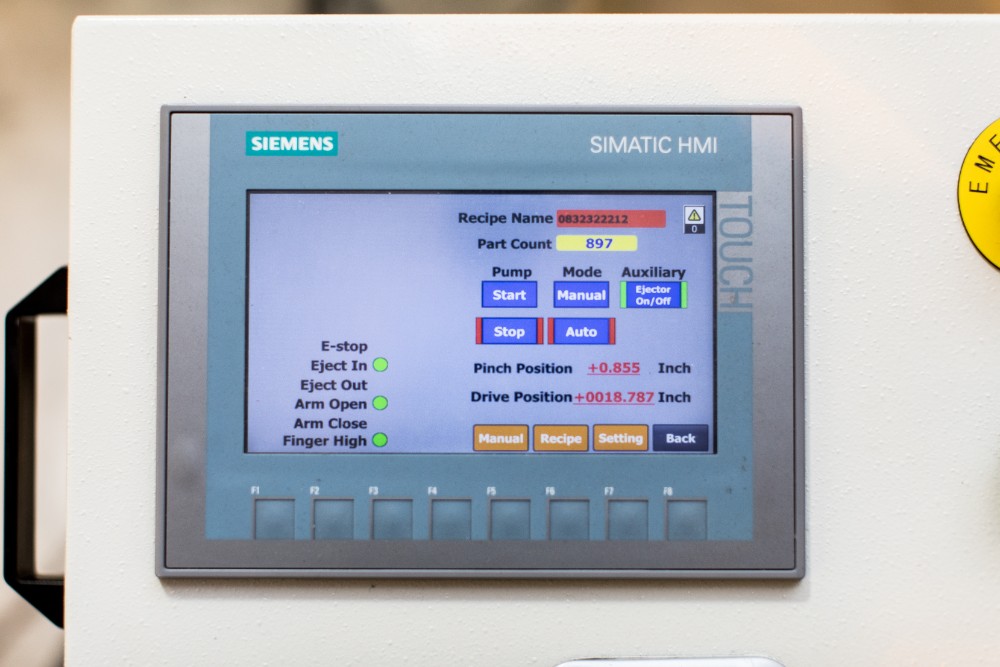

Solution:

Weldlogic Engineering designed a flexible system with position and current based control with fully automatic part management system to enable high quality, fully automatic seam welding. The operator needs only load the ring, and the rest is automated part clamping, welding, and ejection of welded part.

Video

Gallery

Features

- Position & Current Based Control

- Fully Automatic Part Management System

Specifications

N/A

Applications

600 full penetration low distortion welds per hour

Ask our experts about your unique challenge

Previous Product

Dual Auto Laser Welding System