Introduction

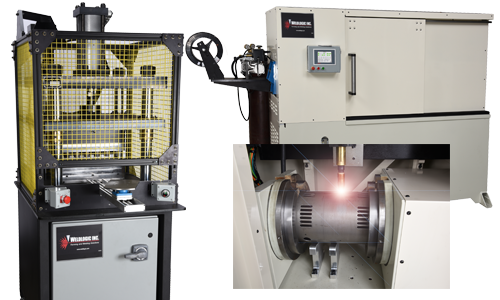

12-Ton Specialized Press Brake

To pre-form the lead and lag of difficult to form materials. Weldlogic engineers have designed a compact 12 ton press with hardened tooling to form the ideal lead/lag edges.

The system uses Air over Oil to deliver the force and the system is controlled by proximity switches and PLC. No skill required to form perfect edges.

Specialized 3-Roll C.N.C. Bending System

Our heavy duty 3 roll machine is a symmetrical roll design. The material is entered into the pinch point between the top and lower pinch roll. The entry side form roll is then placed into position for pre-forming the leading edge of the part. The part is then fed into the machine forming the leading edge.

After the leading edge if formed the entry side form roll is lowered and the exit side form roll is placed into position to finish forming the part. The total process is one entry one pass forming.

High Production Automatic Seam Welder

Weldlogic Engineering were tasked to build an High production Seam Welder, 100+ P.P.H. to accommodate a range of diameters-thicknesses and lengths.

Manually-Load the part into the part cradle seam up & close the door.

View our High Production Automatic Seam Welder

120 Ton Precision Expander

Weldlogic Engineers designed and build a Heavy Duty I.D. Tube expander. This machine is hydraulically driven to produce precise I.D. as required. Replaceable expanding hardened tooling.

Request a Quote

Please get in touch with our team if you have special requirements.

Video

Gallery

Features

- Automatically the system hydraulically compresses the part axially and radially

- The Seam Finder camera servo aligns the torch over seam center every part

- C.N.C. Torch positioning welds the seam over precise length

- Torch retracts to home position / Tooling retracts to home position after each weld

- Door opens to present a perfectly welded tank for easy removal

Specifications

N/A

Applications

N/A