Introduction

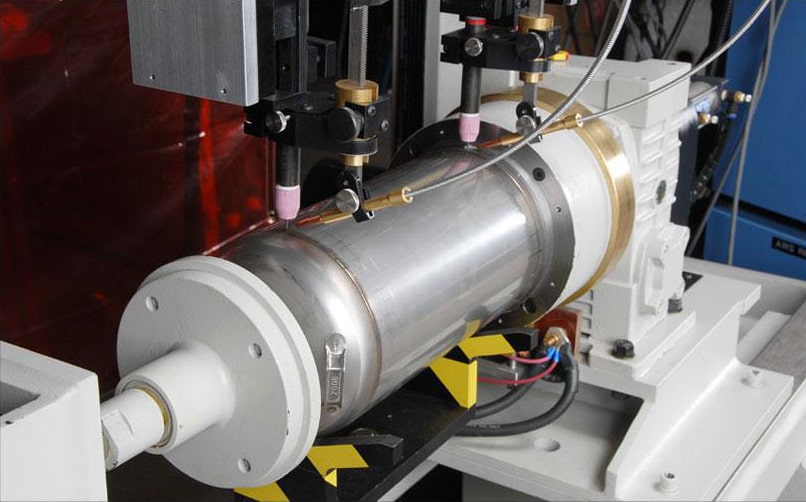

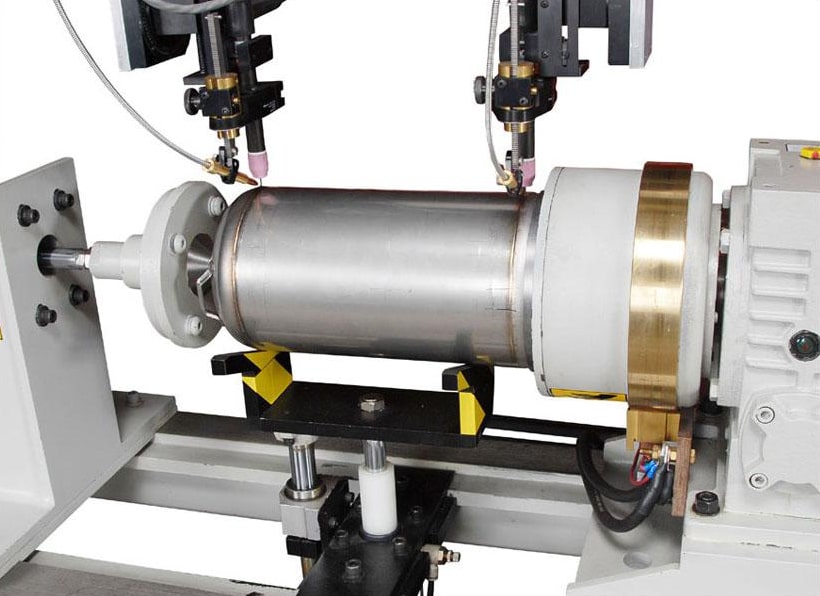

The Dual Torch Tower design doubles production capacity.

Individually controlled torch towers can be positioned for single or simultaneous welding.

Custom pendant interface provide single push button weld sequencing.

Video

Gallery

Features

- Vertical or Horizontal operation

- Square steel tube frame

- Lengths from 15″ to 72″ (work area)

- Welds diameters to 15″

- Precision headstock bearing

- Stainless steel spindle with 1.250″ through bore

- 0-50 RPM speed range

- Self centering 3-jaw chuck

- Motorized torch tower movement

- Air activated torch retract

- Quick positioning tailstock with lock

- Air activated live center with speed and pressure control

Specifications

N/A

Applications

Twin Arc can be added to any of the Weldlogic PWL welding positioners.

With 25 years experience in designing and manufacturing welding lathes Weldlogic sets a new standard in positioner design.

The PWL weld lathes provide the most Versatile, Precision and Rugged welding platform in the industry.

The innovative steel tube back bone construction provides a rigid open work area for part loading and automation upgrades.

Our torch tower is the most versatile available with features like air positioning (in/out) a motorized carriage along the bed plus adjustable slide and rotary positioner allowing torch entry from any angle. The air controlled tailstock provides clamping forces up to 170 pounds for holding part during welding and can be locked into position anywhere along the lathe bed.