Introduction

The Most Accurate Low-Current Welding System

The precision weld fabrication of delicate heat sensitive assemblies is now a practical reality. Finally, there’s an alternative to complicated and costly beam welding systems.

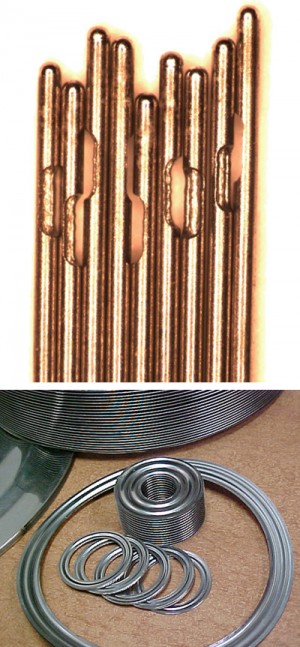

Very low heat, high speed welds can now be made in materials as thin as .001″ and as thick as .125″ with the Weldlogic PA-10/100-STD. Thousands of these productive systems are in daily use throughout the world. This unique state of the art dual range, 10 amp/100 amp, precision pulsed arc welding system is the result of years of research in low current arc starting and control stability.

Weldlogic’s unique “snap on” arc initiation prevents start pulse overmelts in the most delicate of welds. This gentle starting system also extends Tungsten life. Closed loop servo control of welding current and direct reading digital controls make this the most accurate low current welding system on the market today. Millisecond square wave arc current pulsation produces a narrow low heat weld consistency.

We maintain a staff of experts in the speciality of precision welding and automation.

Contact us or your local representative for a free evaluation of your welding requirements.

Video

Gallery

Features

- 110V, 230V 50/60 cycle operation

- Ultra-low current system can soft-start and weld at 0.1 Amperes

- Soft-start greatly extends Tungsten life

- Dual range from 0.1 ampere to 100 amperes

- Welds materials from .002″ to .125″

- 100% solid-state closed-loop servo control design

- Increases weld speed by up to 60% or greater

- No arc wander, with current as low as .1 amp

- Portable, lightweight