Introduction

CHALLENGE

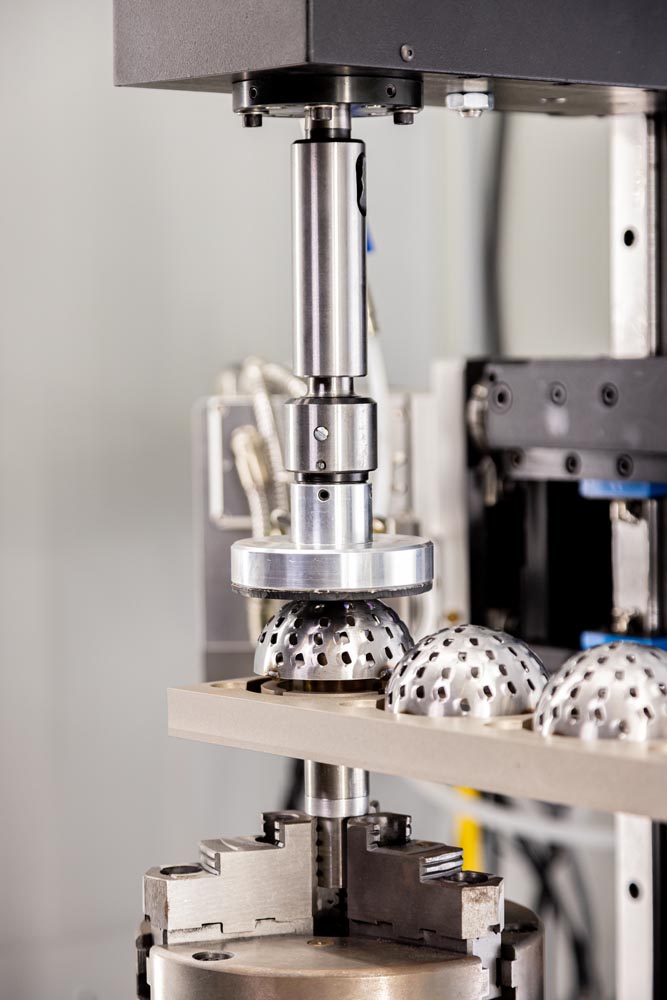

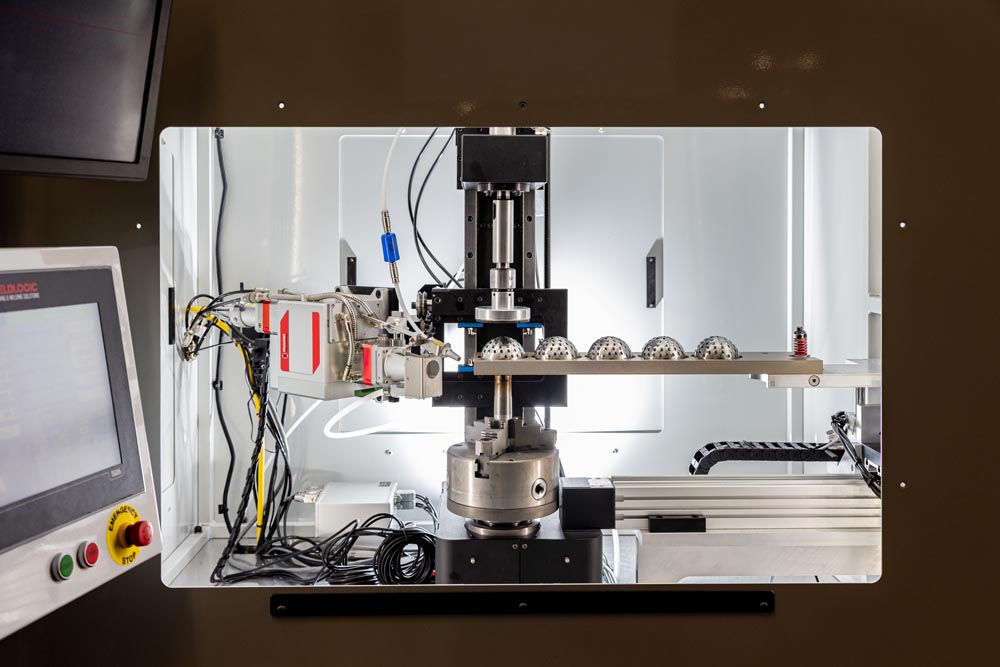

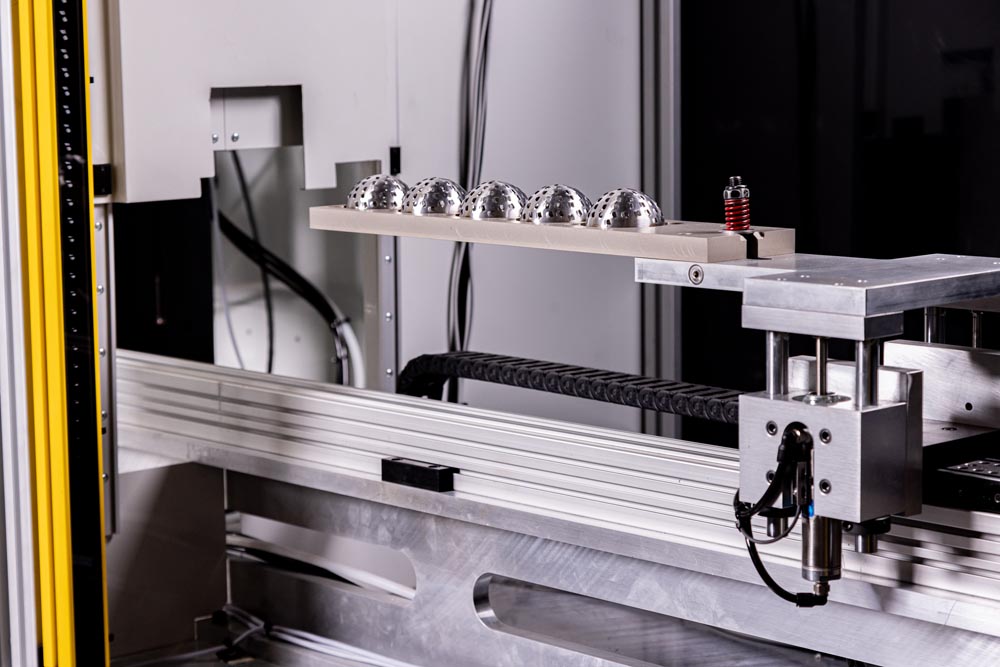

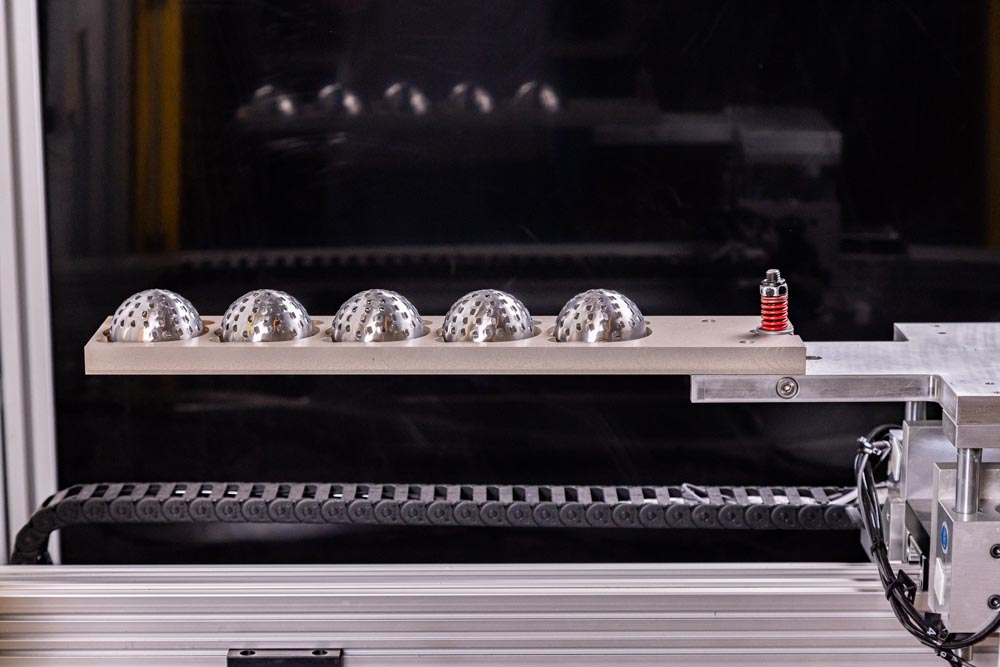

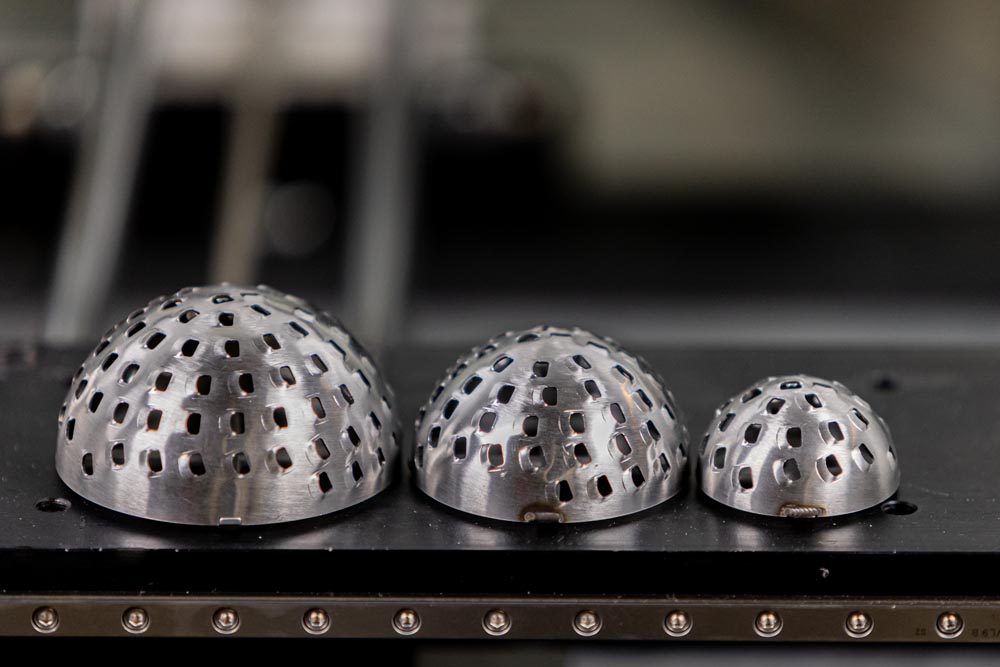

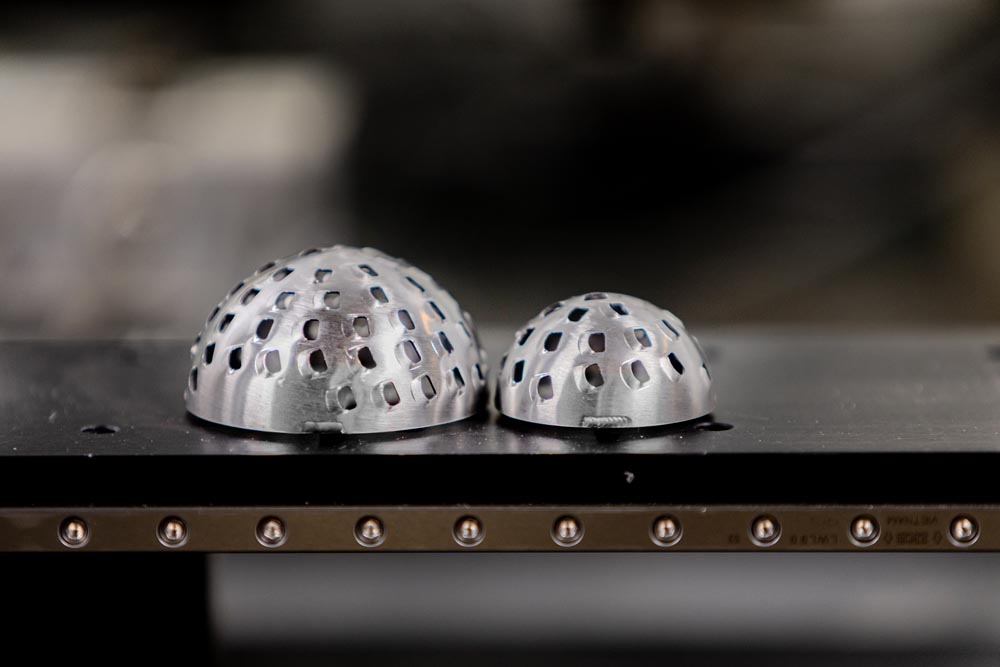

Weldlogic Engineering was challenged by a Medical Device Manufacturer to develop a production qualified welding process that eliminated the current GTA-TIG welding process and automate the welding to a level that would enable all the welds on 5 assemblies at a time to be welded while the operator ran other assembly cells.

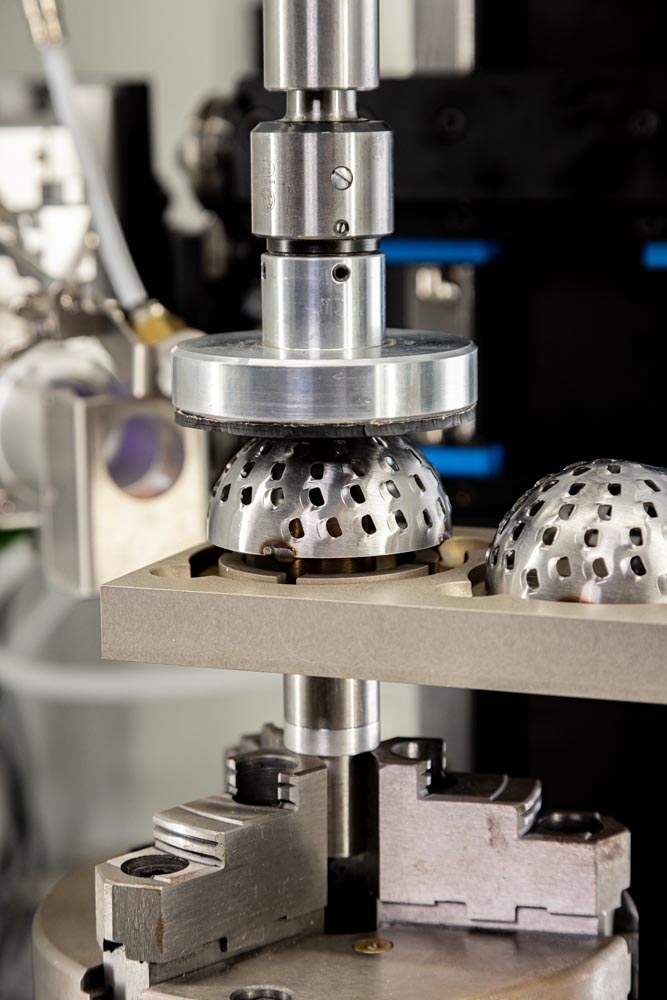

The weld was challenging due to the new product design requiring thin wall laser welds to thick cross member structures. If successful the machine and weld process would reduce labor, skill and increase productivity.

SOLUTION

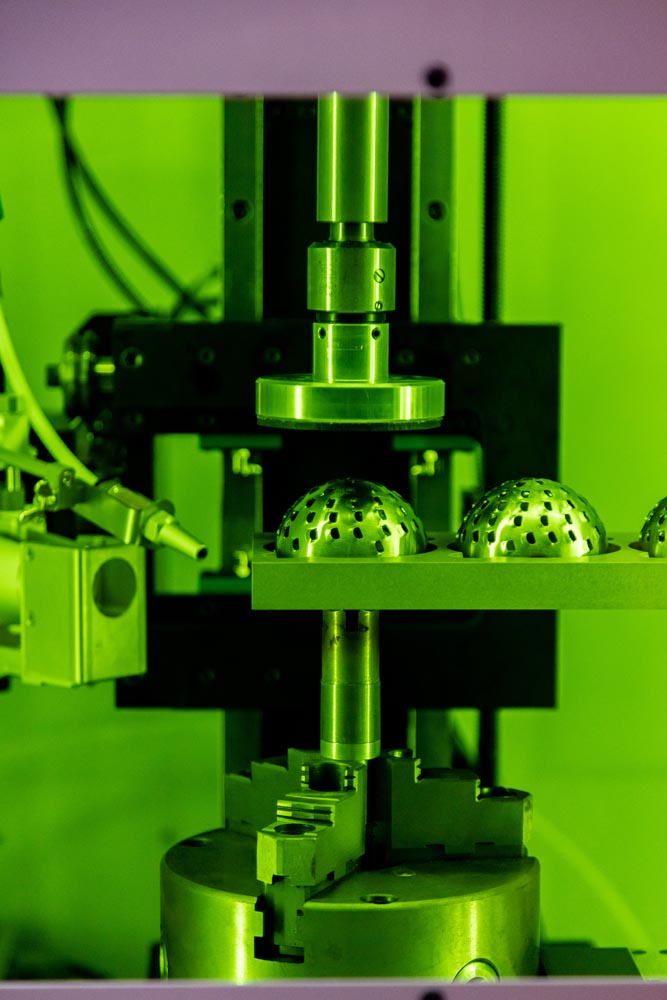

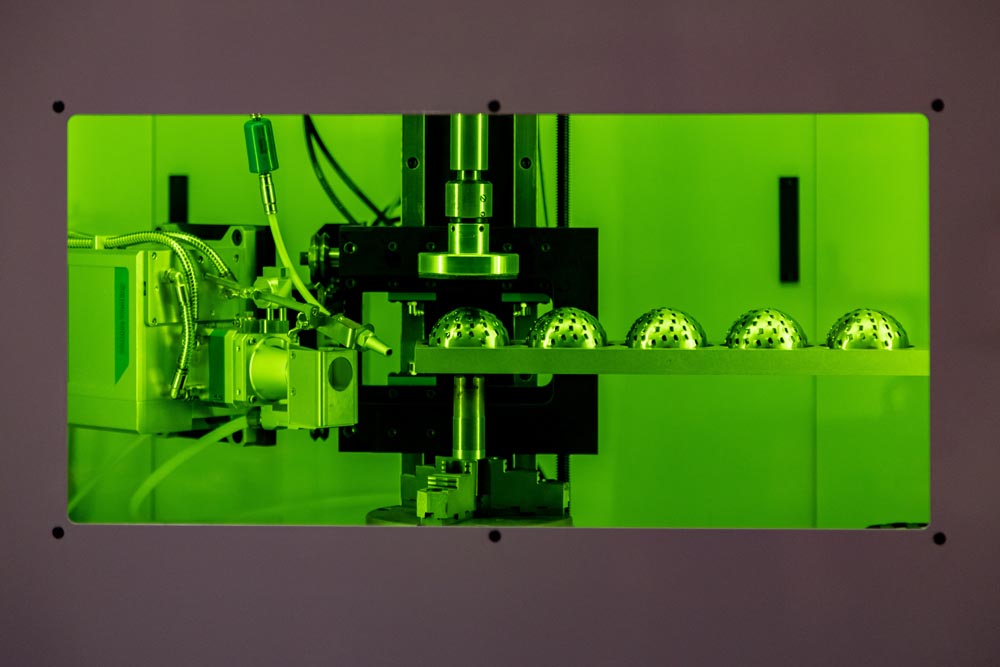

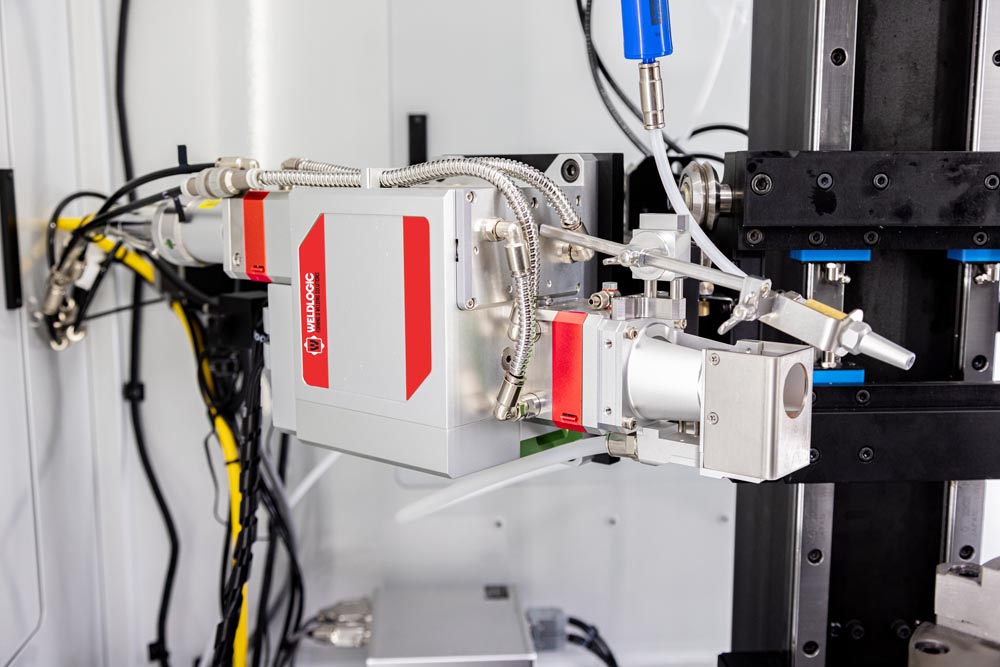

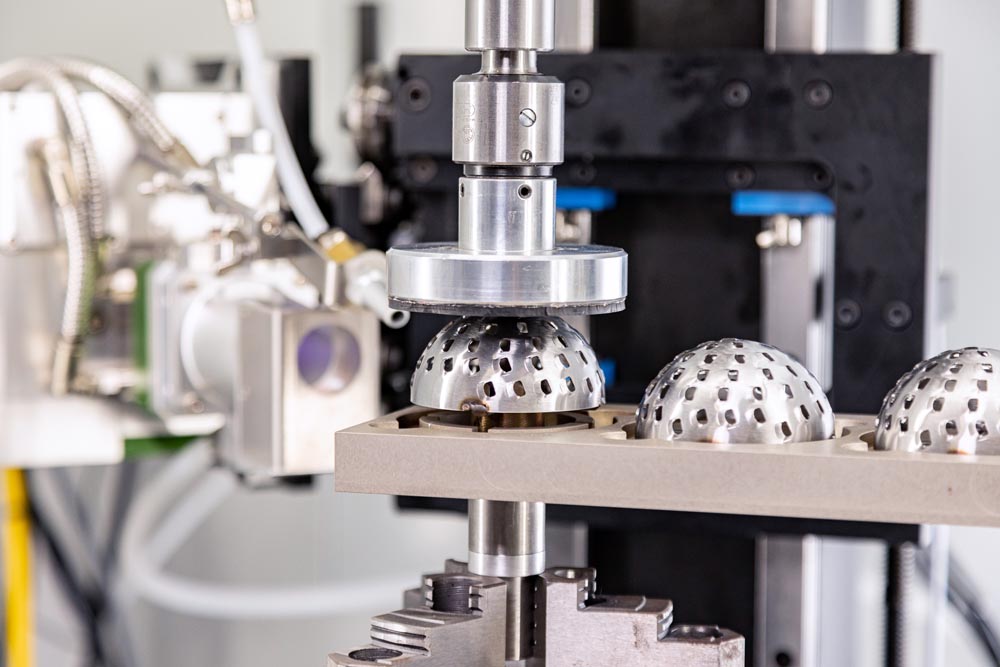

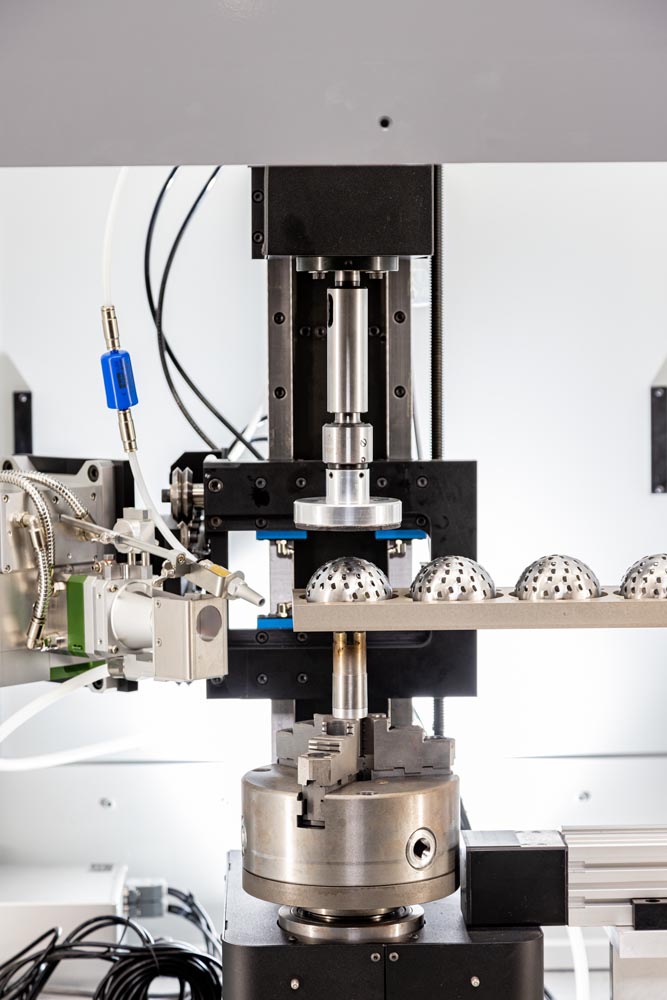

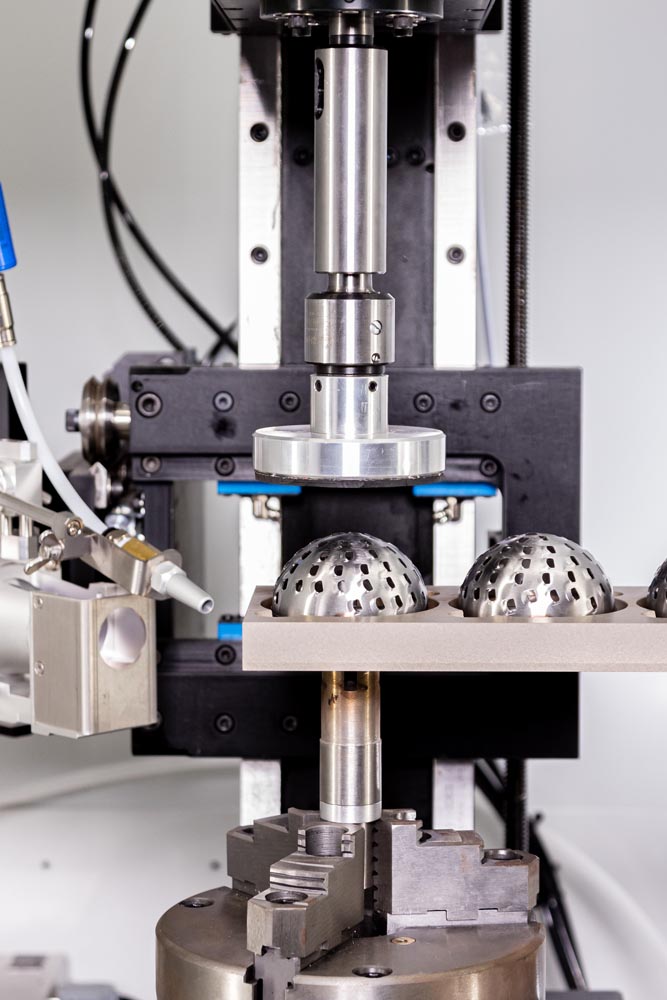

Weldlogic Laser-Lab developed a laser weld process using our AWS-2000-watt fiber laser and to wet in the thick to thin structure to thin wall dome used a Laser Beam Oscillator/Wobble to enable a wide bead width to weld.

This development proven out in our Laser-Lab by our specialists solved the thick to thin structure welding challenge, yielding a strong smooth weld with virtually no distortion.

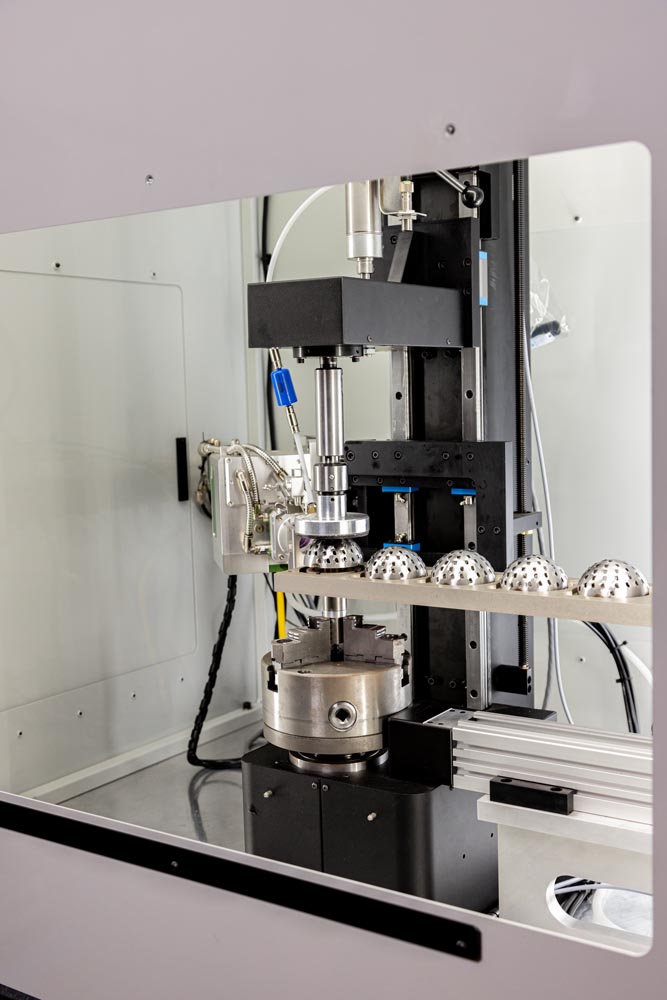

Weldlogic Design Engineers, after weld validation established, designed an auto-part feeder combined to integrate into our multi-axis weld cell. The resulting system eliminated operator welding skills, and reduced labor content by 75%.

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A