Introduction

Challenge:

An Aircraft Fire Extinguisher manufacture needed to replace the decades old manual GTAW/TIG welding process used to Stainless & Titanium pressure vessels to the highest welding standard.

The manual welding process on their flight hardware & vessels produced Low Parts per hour, High Heat input, High Scrap Rates and High Skills levels with no traceability other than X-Rays.

Solution:

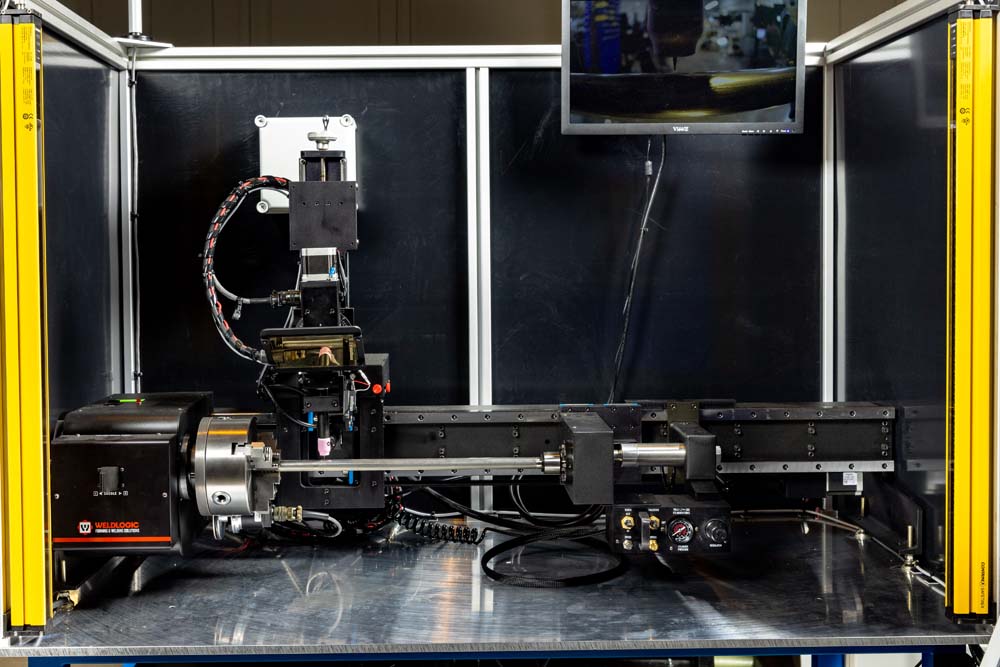

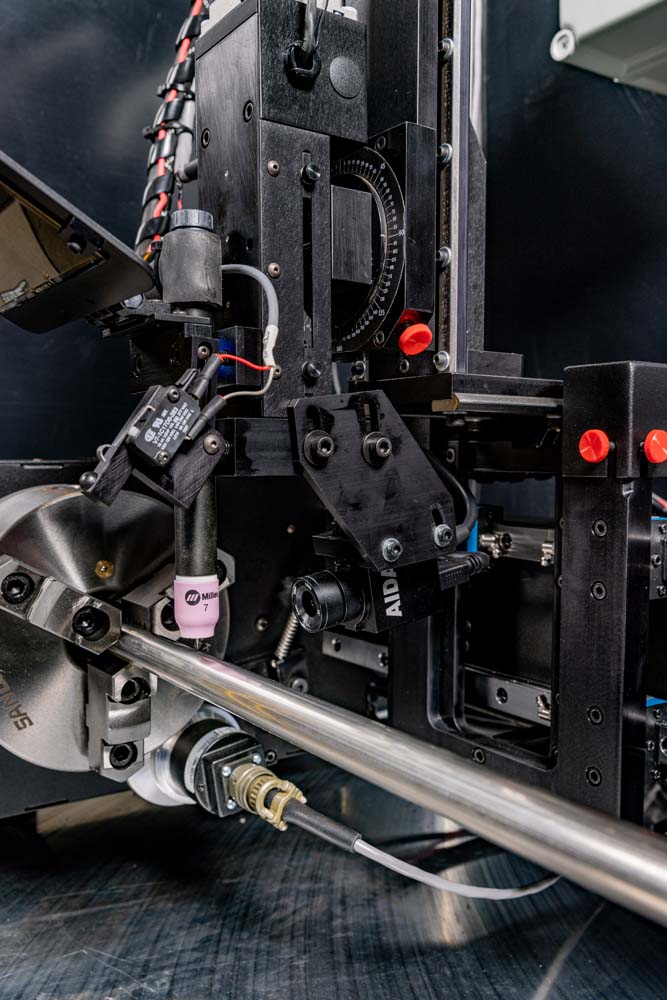

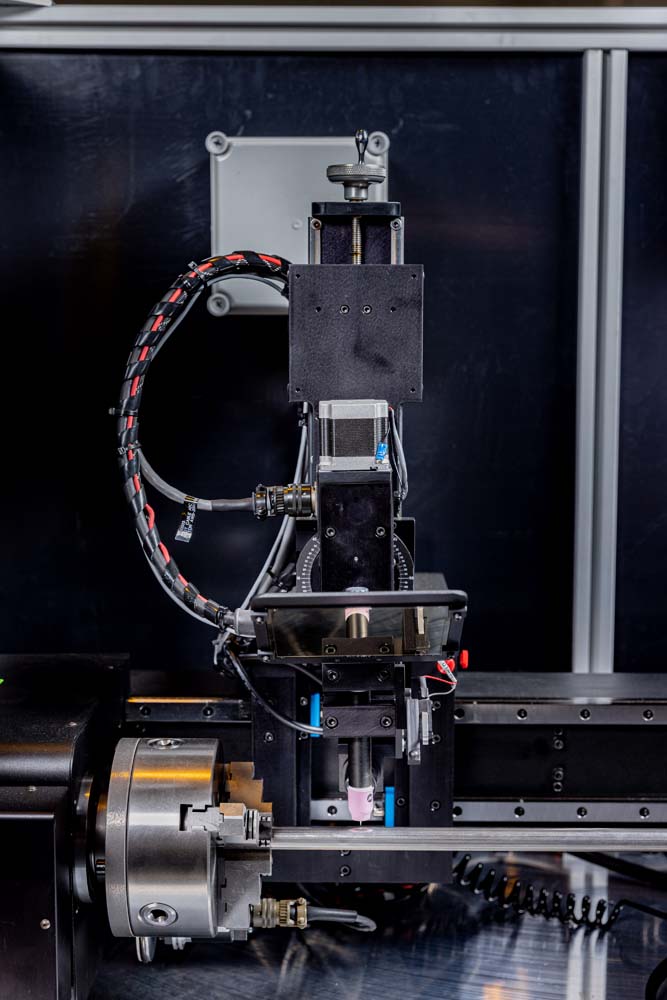

The Aircraft Fire Extinguisher manufacture selected Weldlogic to develop and optimize their GTAW weld process to enable them to eliminate the manual welding process and solve many productivity challenges.

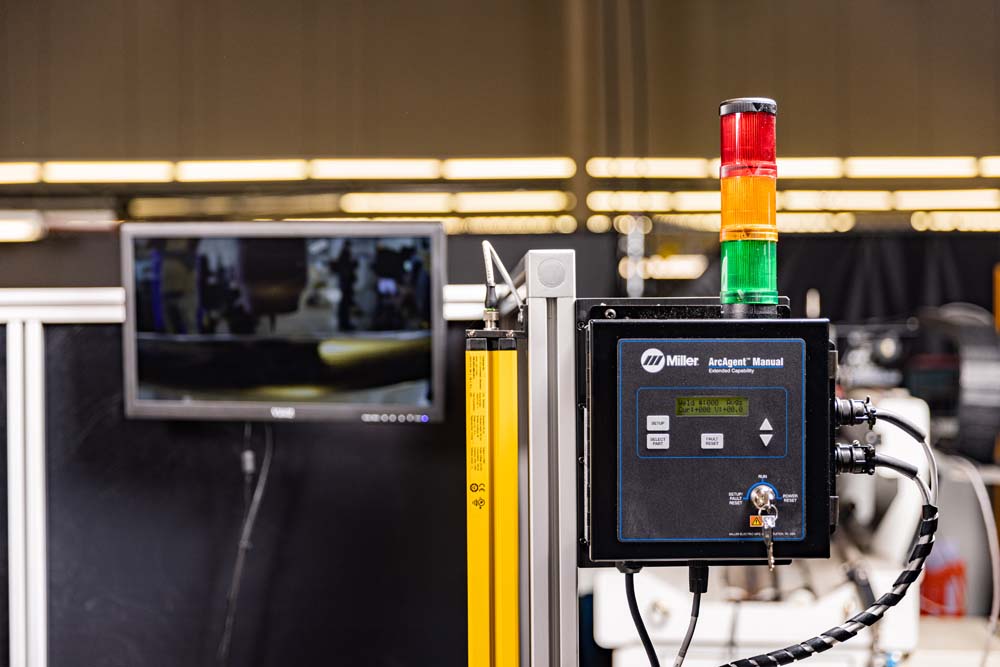

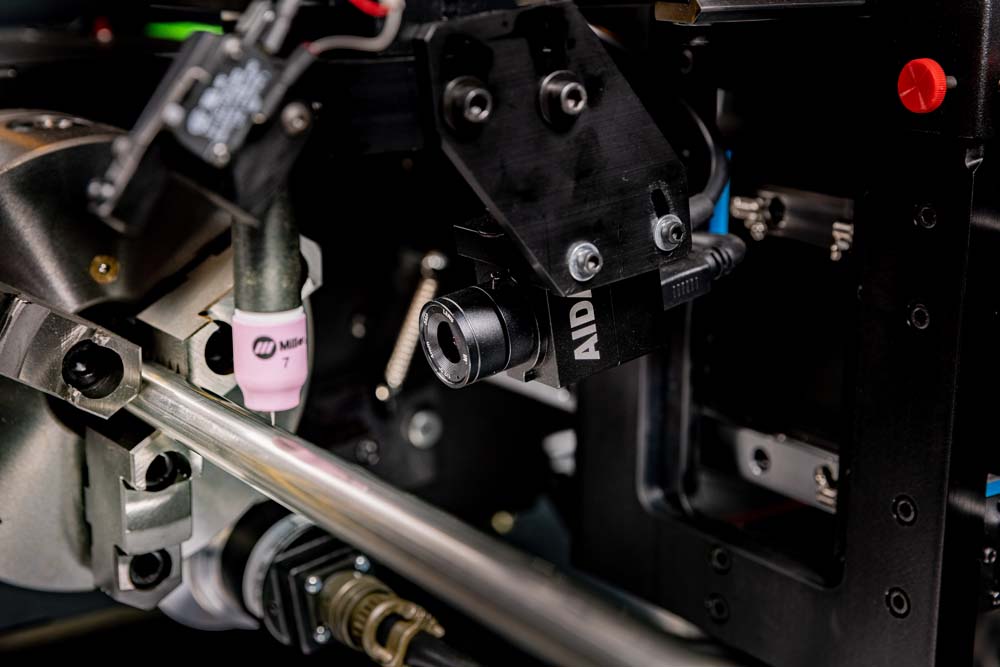

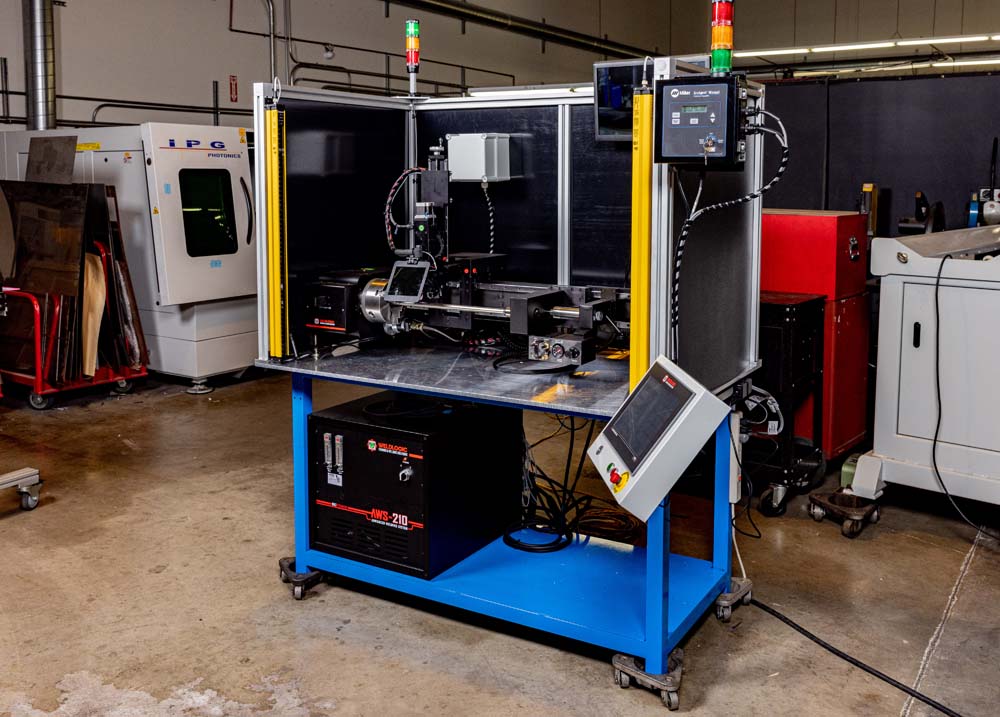

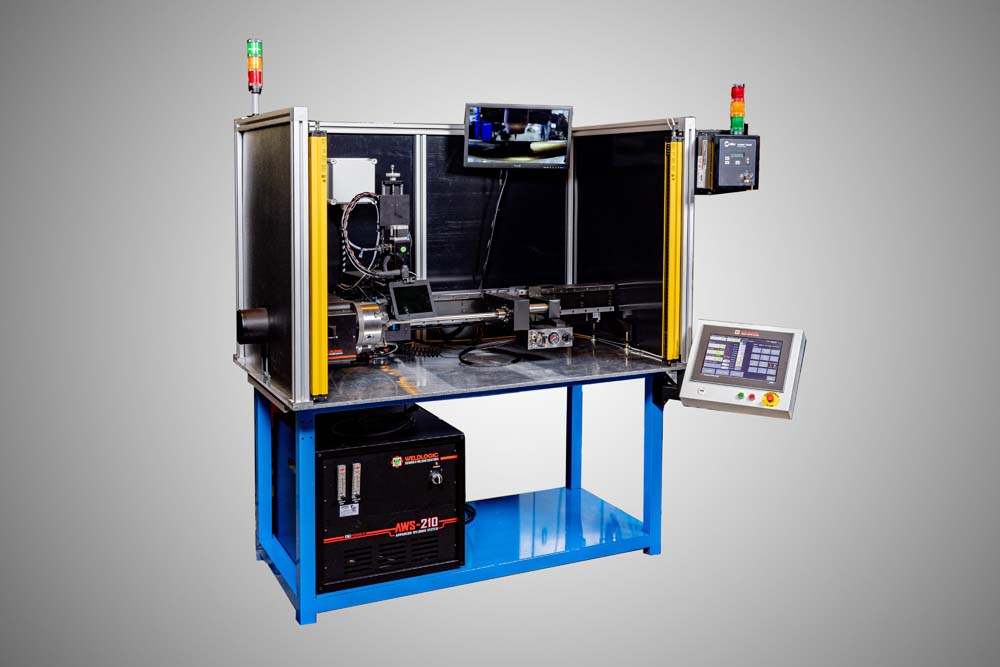

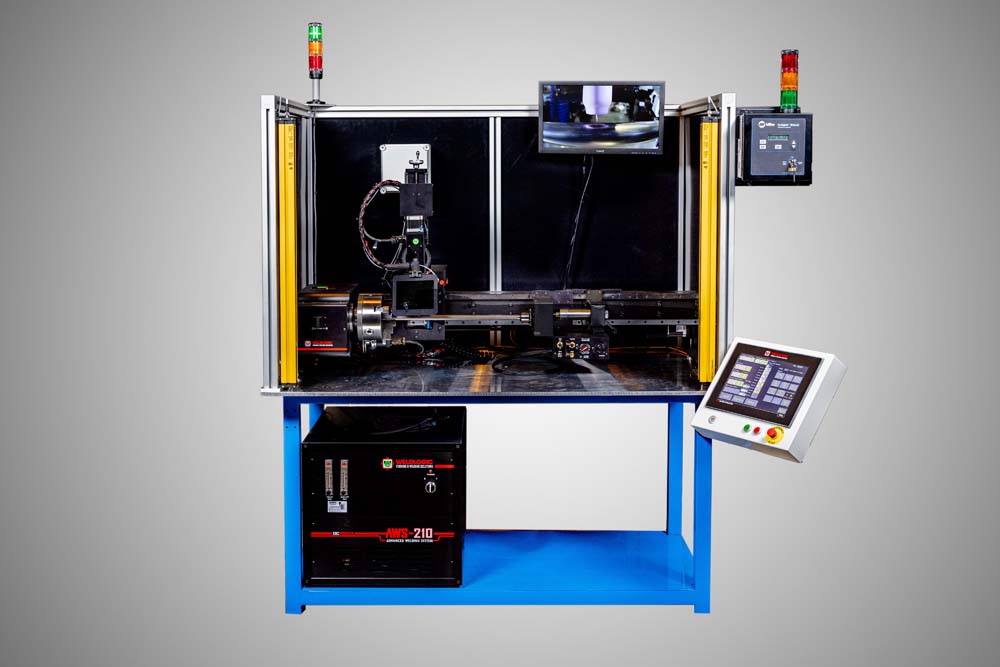

Weldlogic Engineering and Process Weld Specialists assessed the many critical welds required and productivity goals and offered an AWS-210 Advanced Welding System, with Weld-Data Tracking and validation of process reports.

The Weldlogic AWS-Weld Cell eliminated 85% of the manual welding & provided a very repeatable weld result ±1% or better with documentation for Q.C.

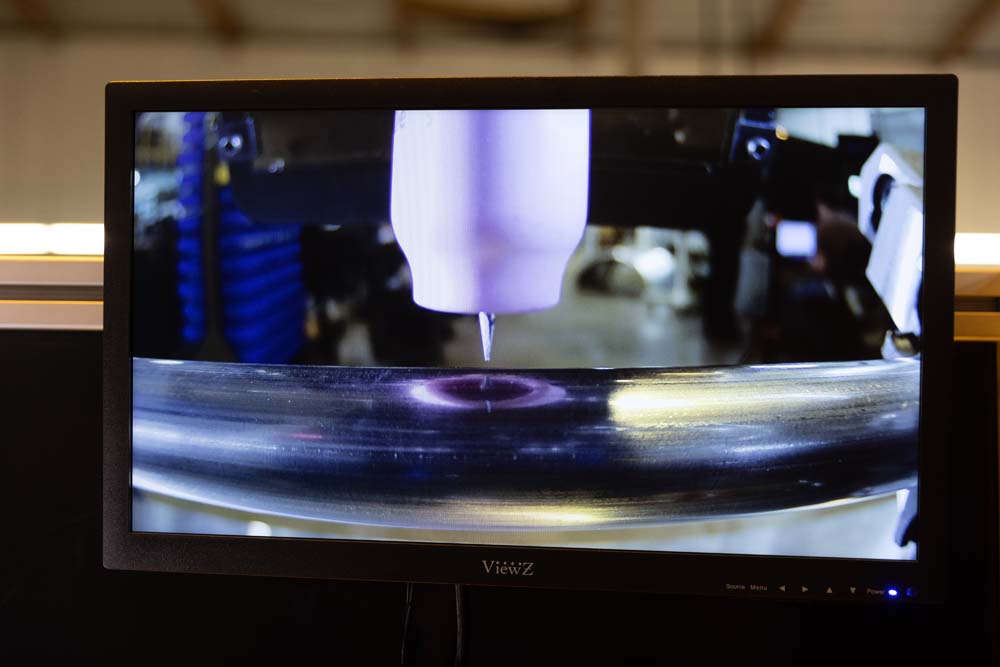

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A