Introduction

Challenge:

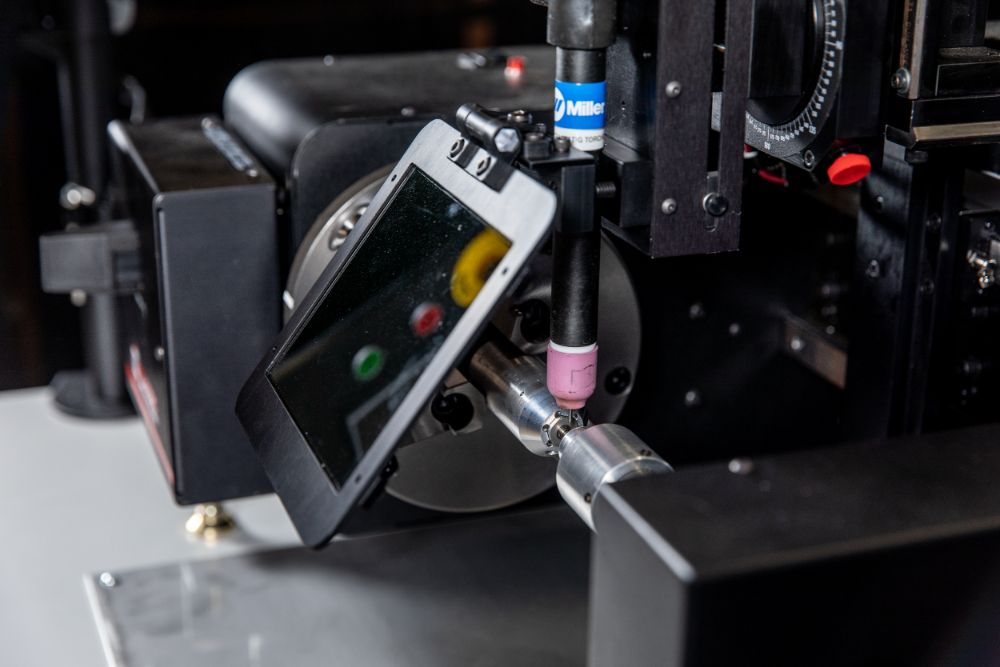

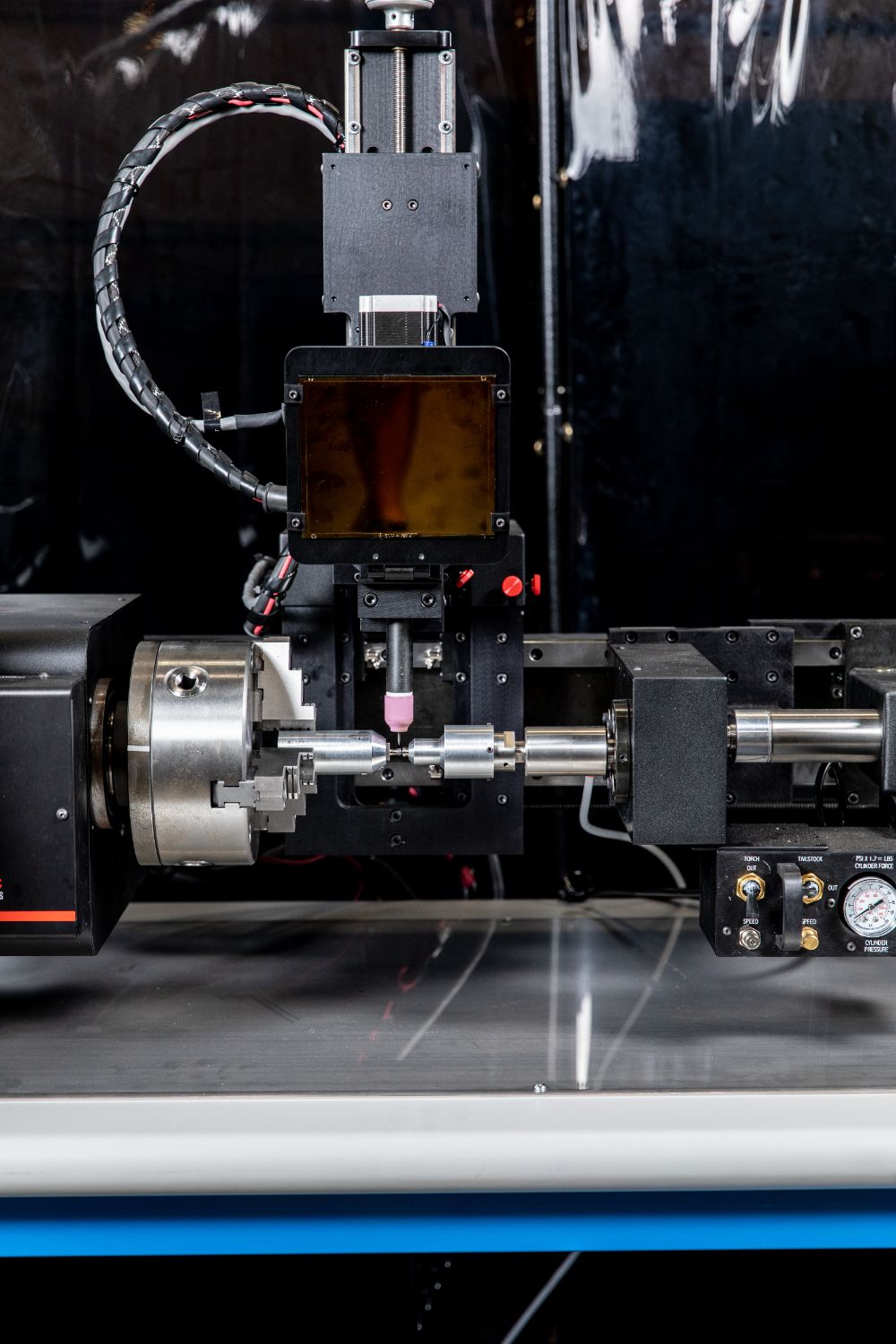

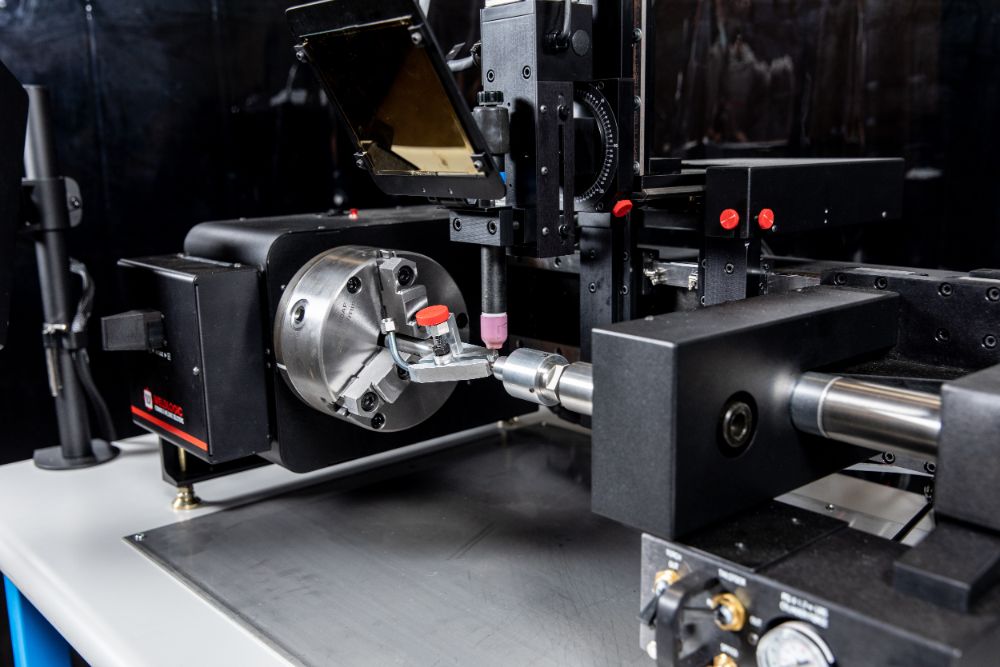

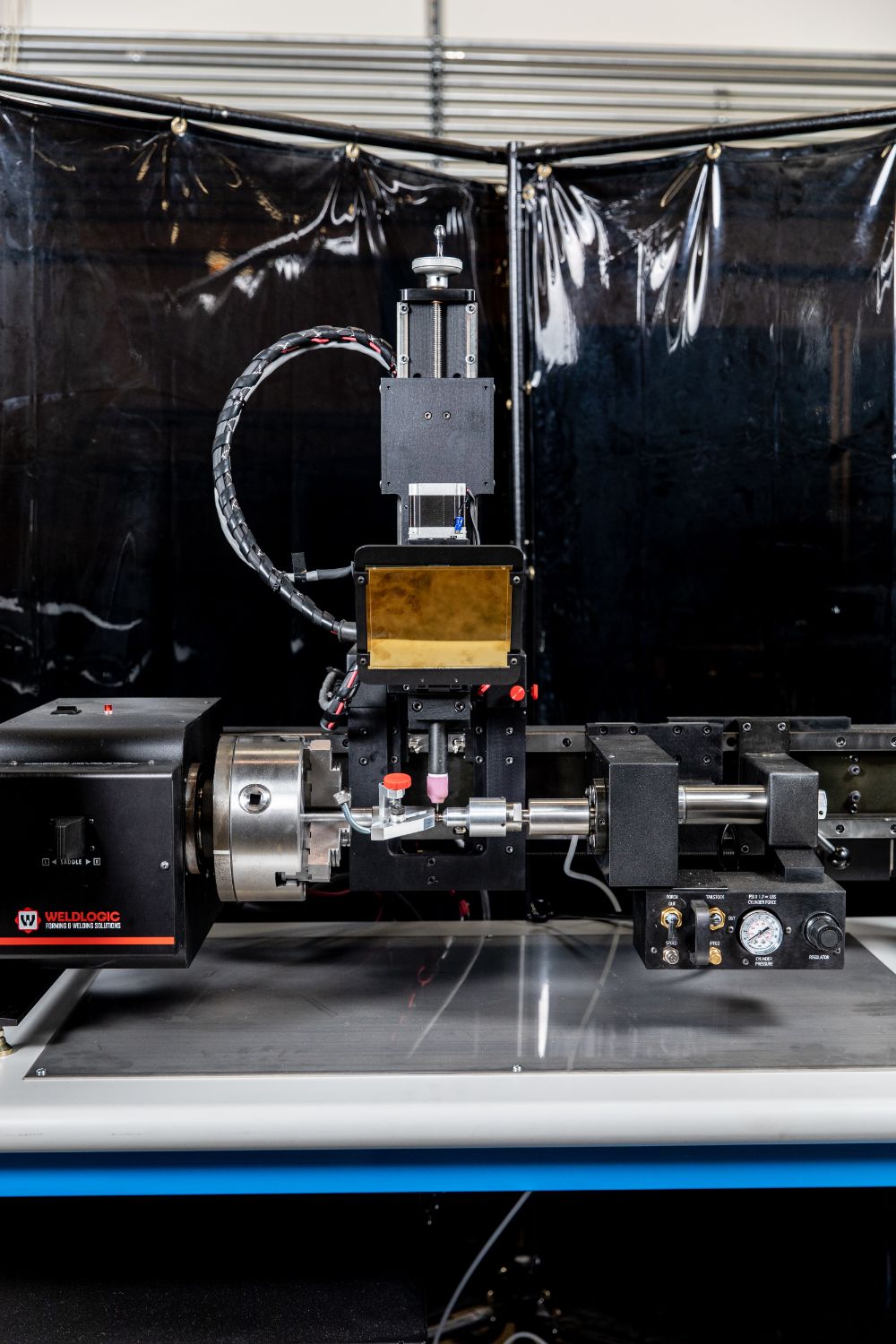

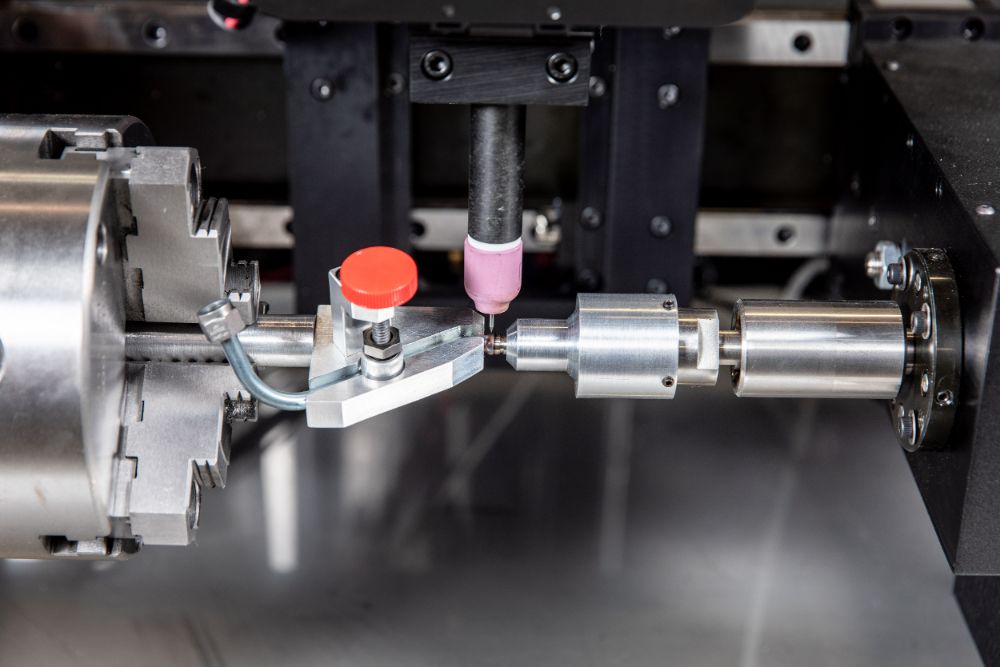

Take a Weldlogic Standard AWS- 6100 System that uses the GTAW weld process to automate a difficult hand weld of a fitting to couplers and fittings to multiple variations of bent tubes.

The welds have to be x-ray clear and special tooling had to be designed to enable a non-welder / operator to make highly repeatable automatic welds

Solution:

Weldlogic Engineering designed quick change tooling to place the challenging tube assemblies and fittings on rotational center to enable easy and repeatable automatic GTA Welding.

The Weldlogic AWS-210 offered Heat Tapering around the tube diameter to insure perfectly uniform welds and meet all the quality requirements.

Each Weld schedule was stored in the HMI memory and thumb drive to back up the system and keep on your office P.C.

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A