Introduction

Challenge

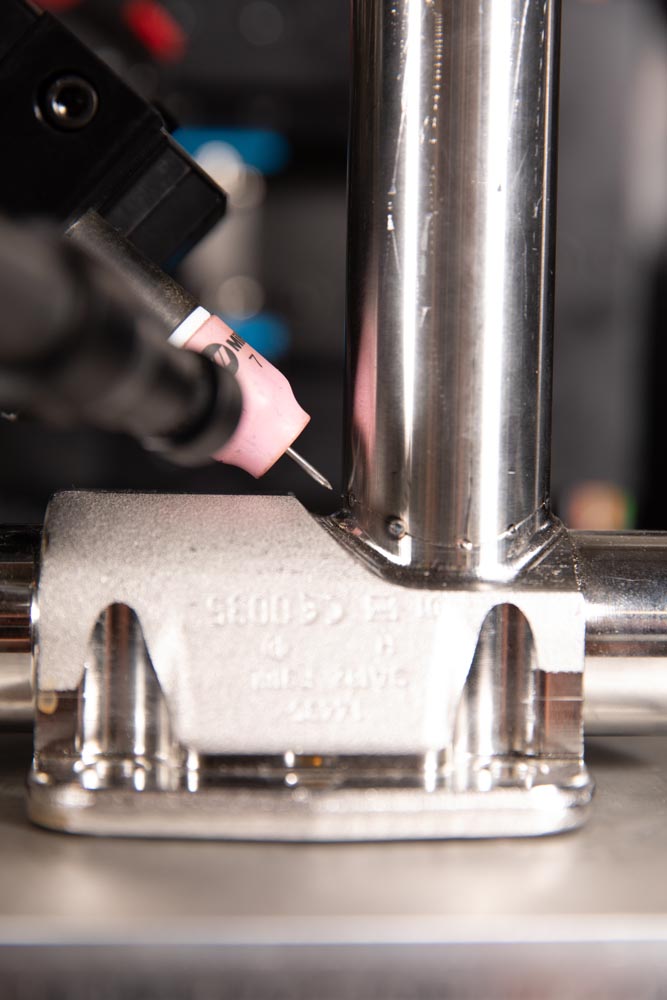

The customer has over 3000 high purity valves variations with various saddle weld contours to program.

Their operators are not C.N.C. weld programmers and as such need an easy way to program two axis rotary saddle welds.

Solution

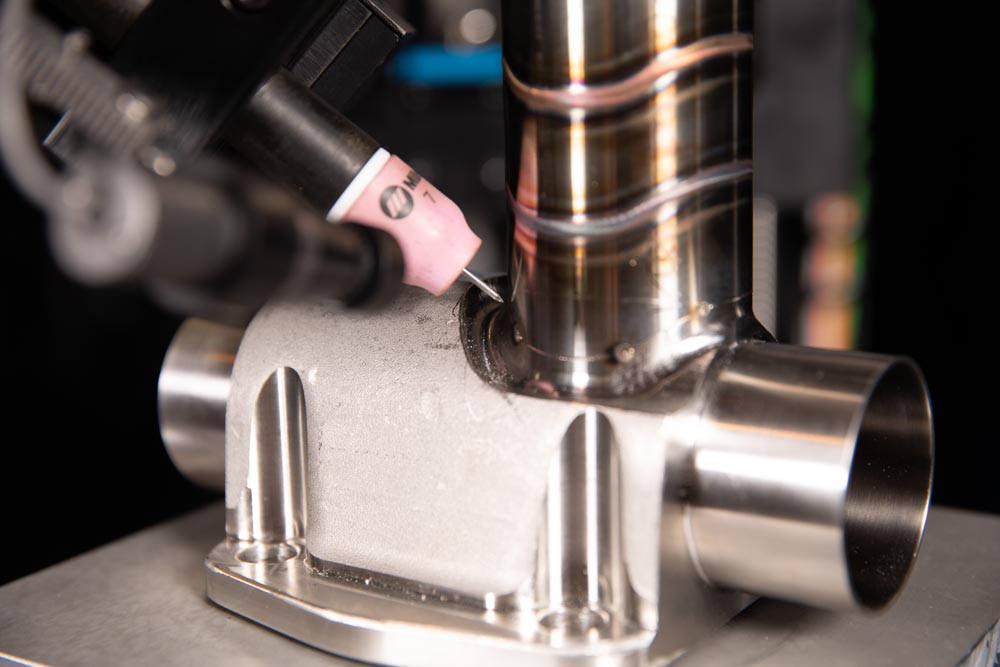

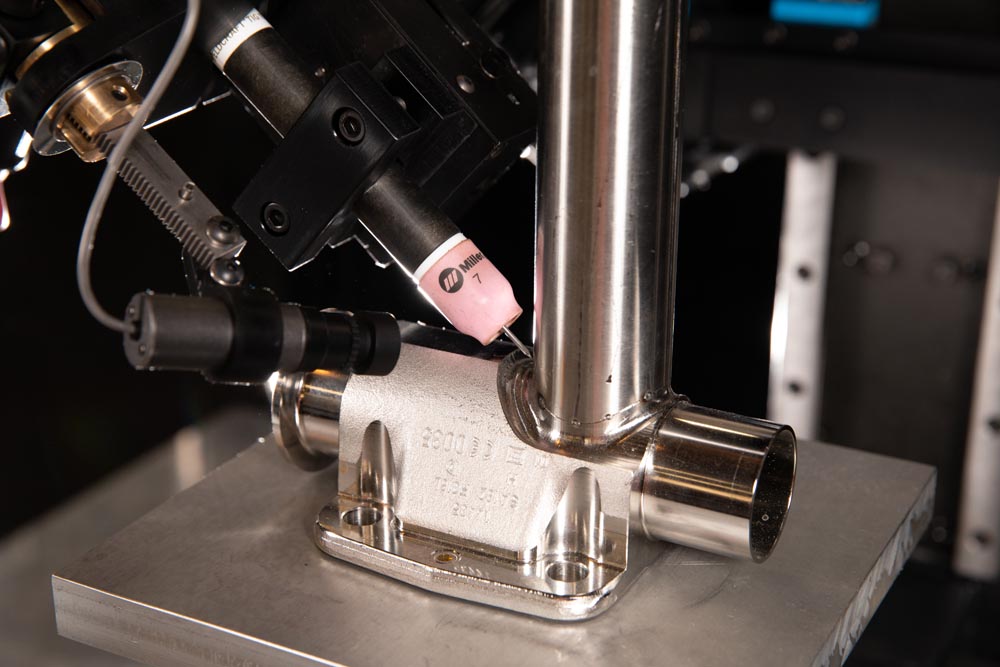

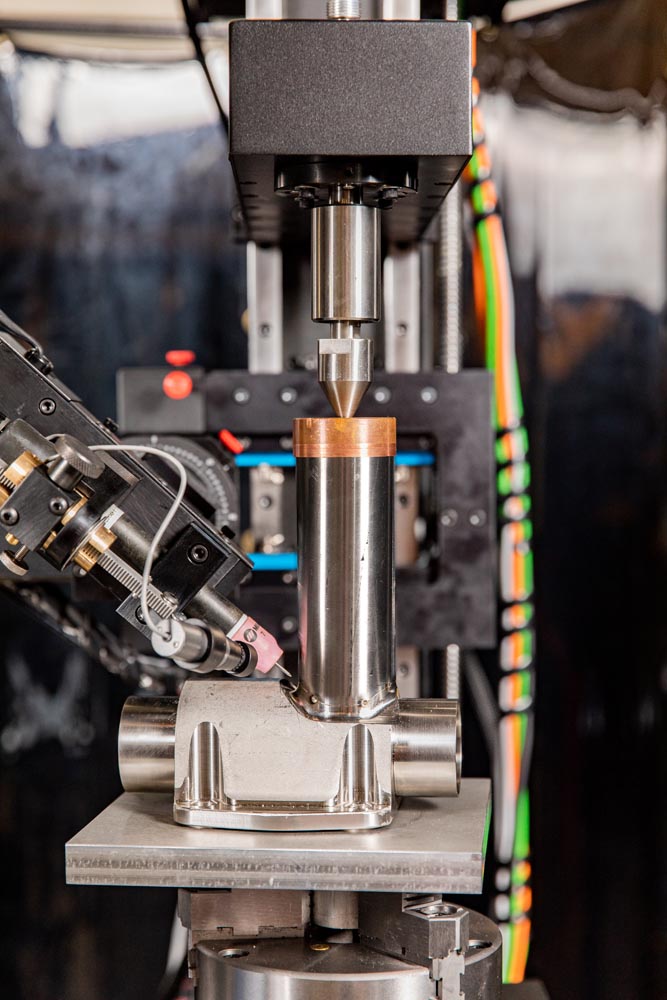

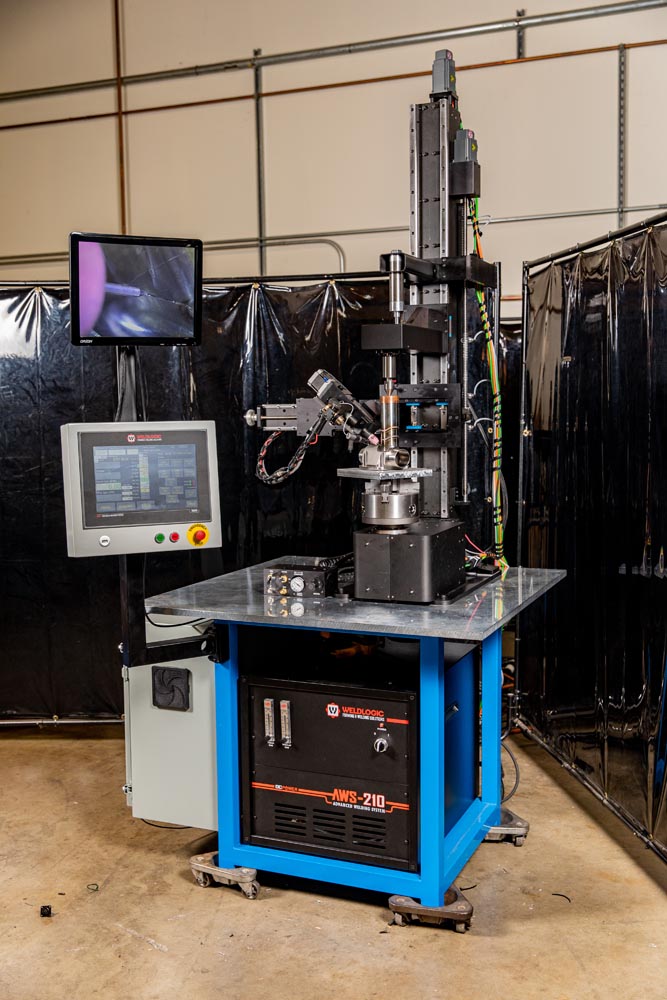

Weldlogic Engineering, creating a 2 Axis C.N.C. lathe in a vertical position with a teach program mode to enable any operator to program and save the complex saddle weld contour.

The operator enters the diameter of the tube and places the electrode over the weld seam and enters the position in 4 key positions and the system configures the path needed.

All programs can be saved to memory for immediate recall as required. This solution was an elegant use of Weldlogic Engineering to eliminate a customers need for a Programmer / Welder.

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A