Introduction

Challenge:

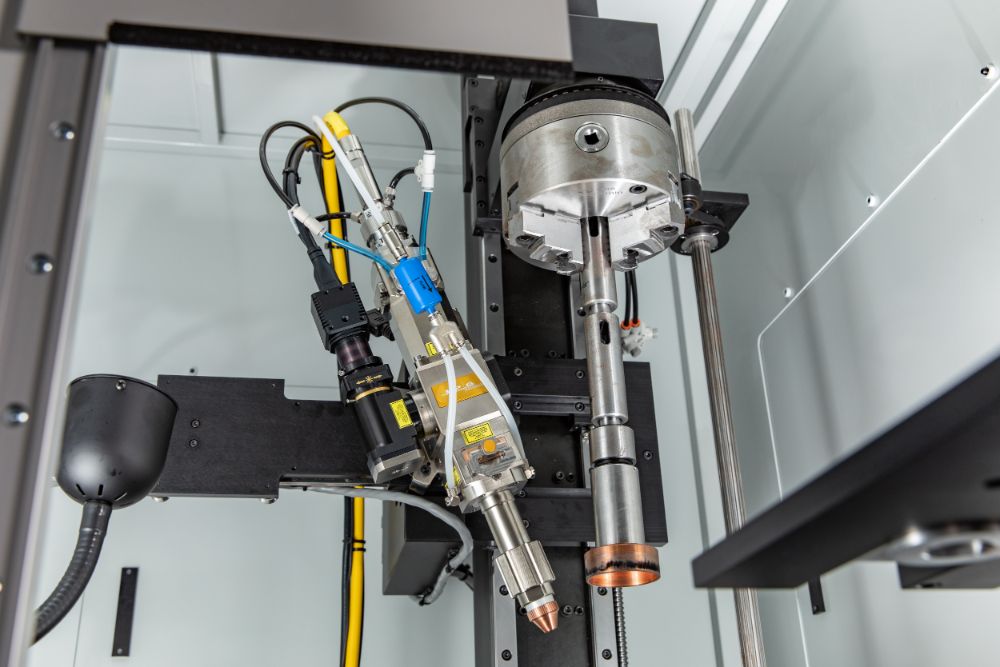

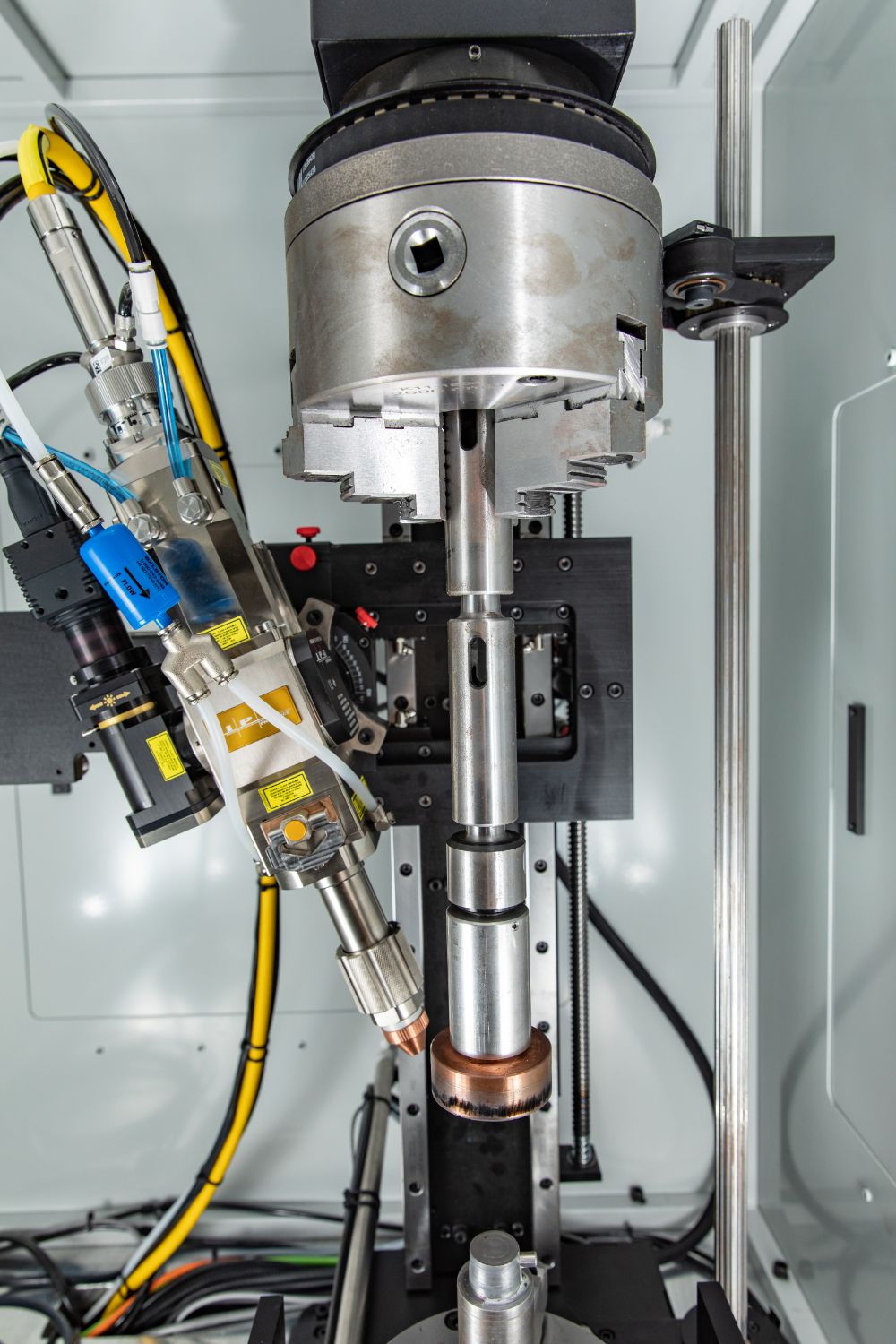

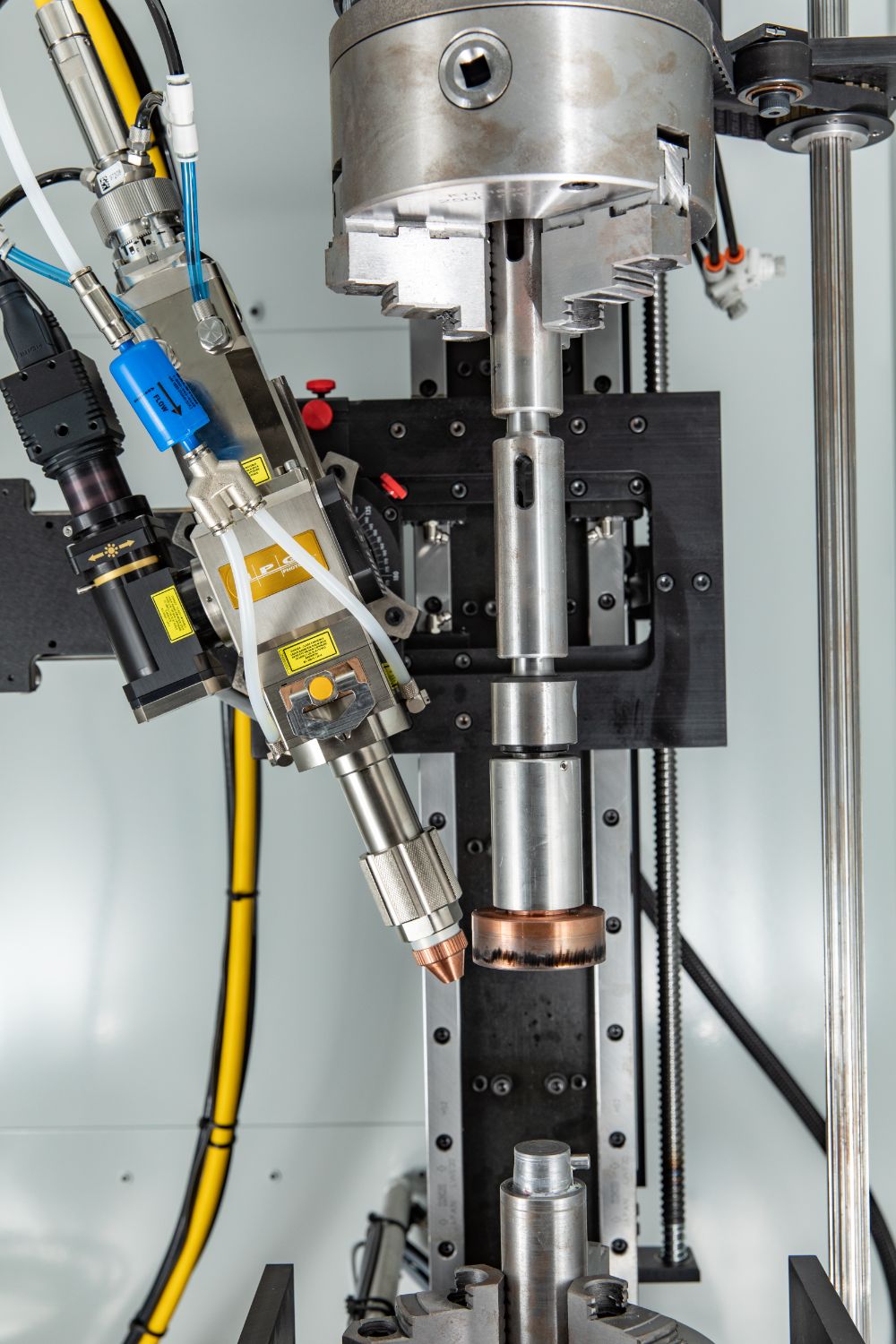

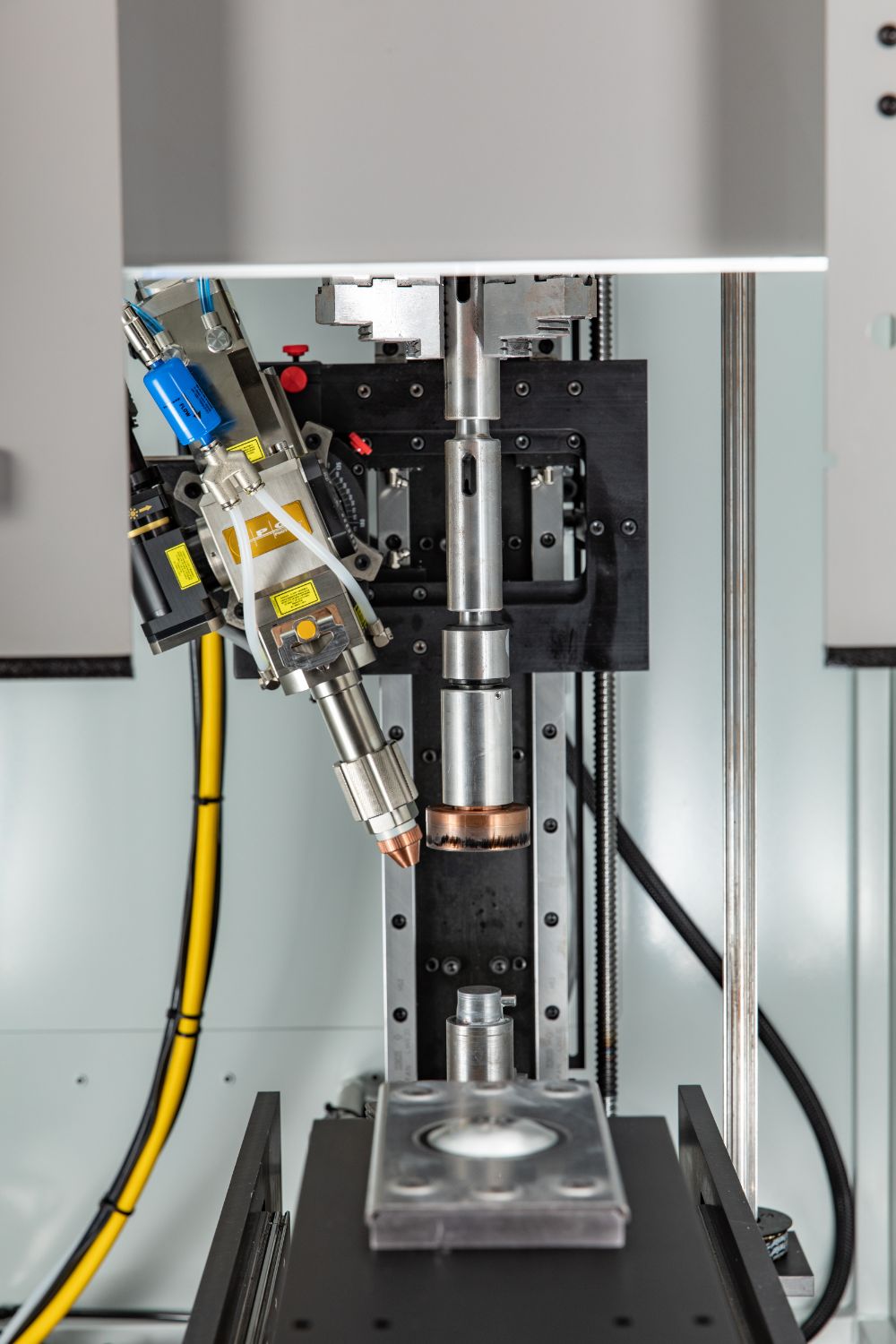

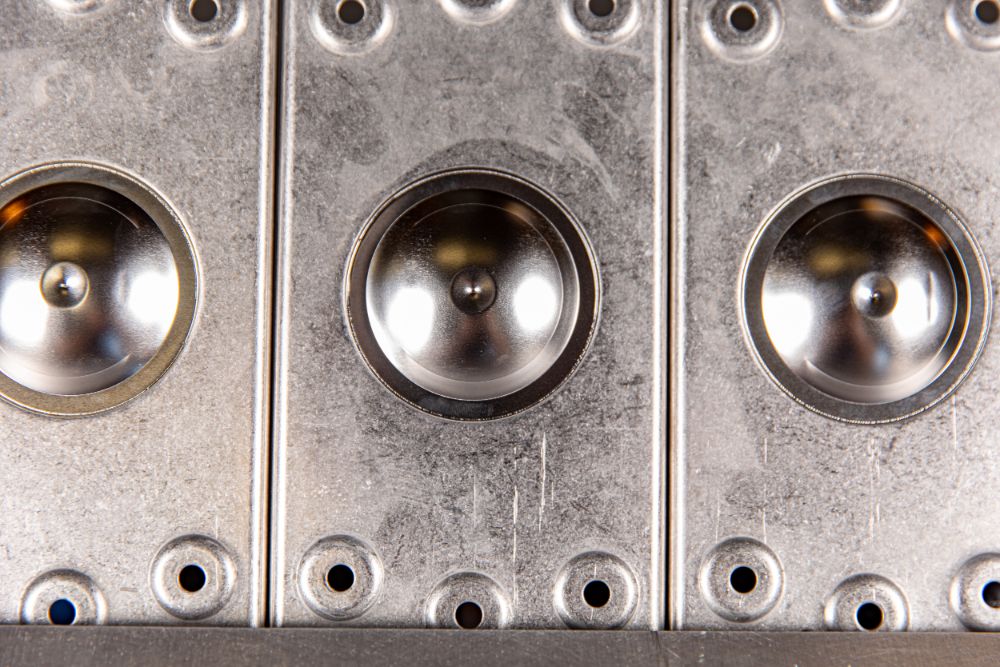

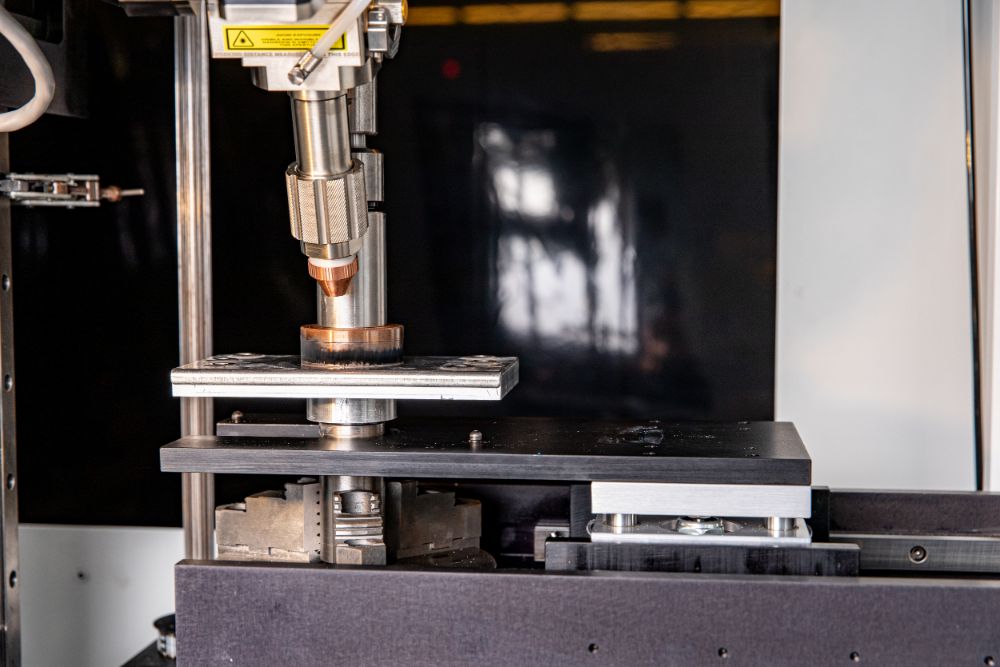

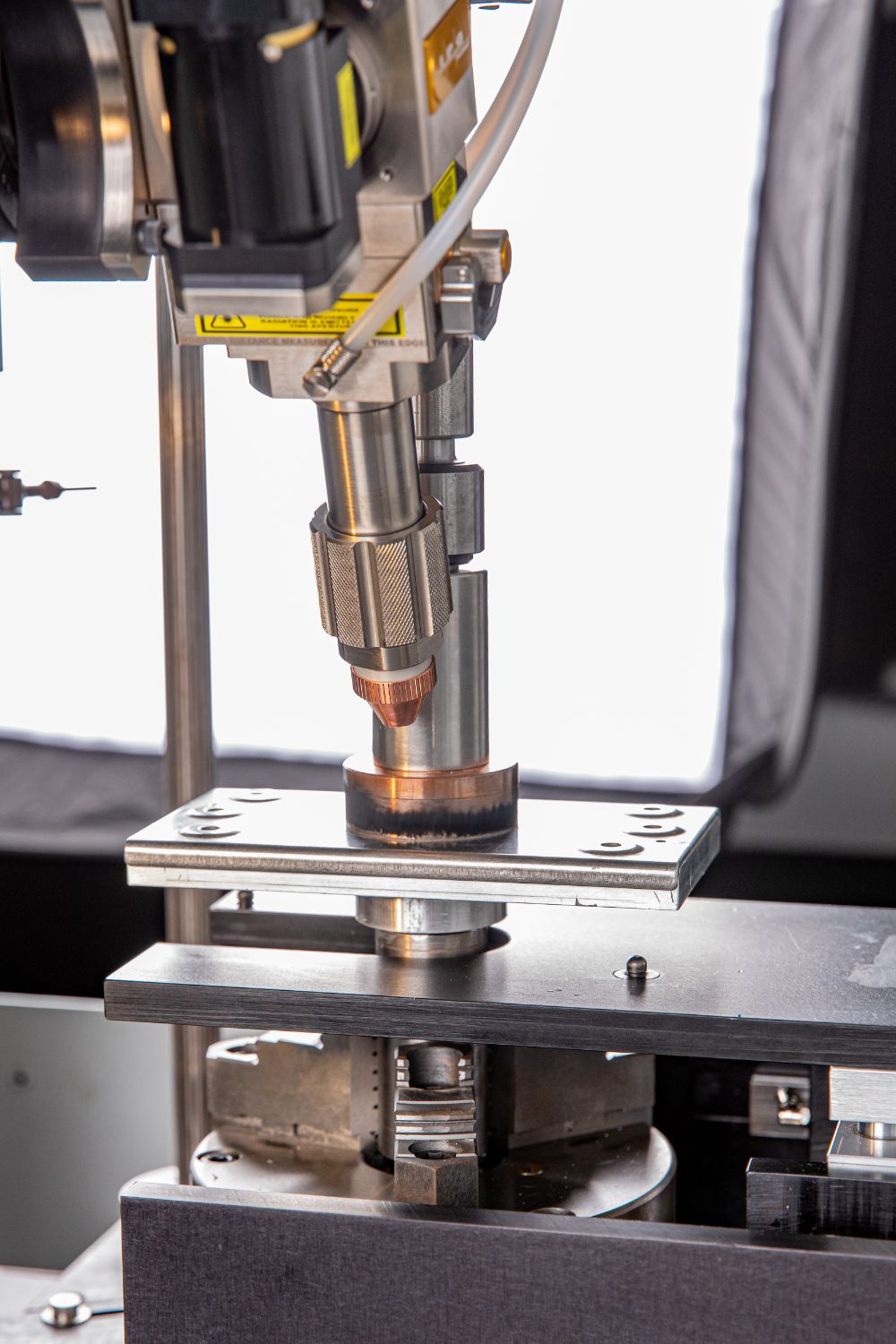

Design and Build an automated welding system to enable automatic leak tight seal welded between a .0025” thick S.S. burst diaphragm to a heavy wall S.S. assembly.

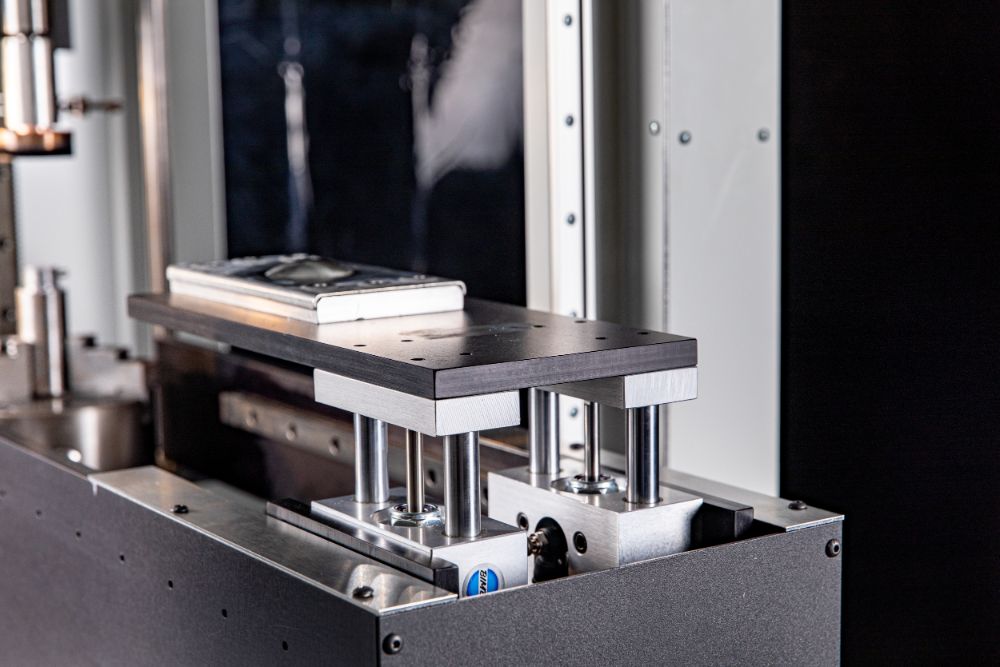

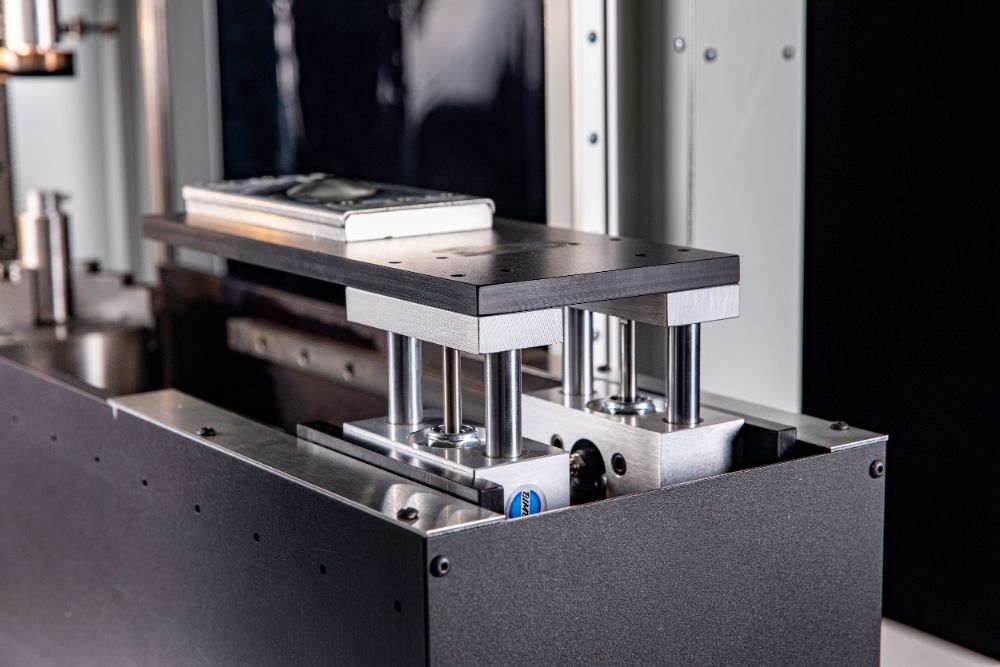

The system has to precisely hold and position the assembly to enable the laser to penetrate both materials with high speed and high degree of repeatability.

Solution:

Weldlogic engineers designed tooling and auto feeder to precisely place the delicate .0025” thick S.S. burst diaphragm on the thicker base assembly in a manner to axially clamp the two loose assemblies and create a high speed precision laser weld.

This system enables any assembler to simply place the two parts onto a carrier that brings the parts into the laser cell for processing and back out.

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A