Introduction

Challenge:

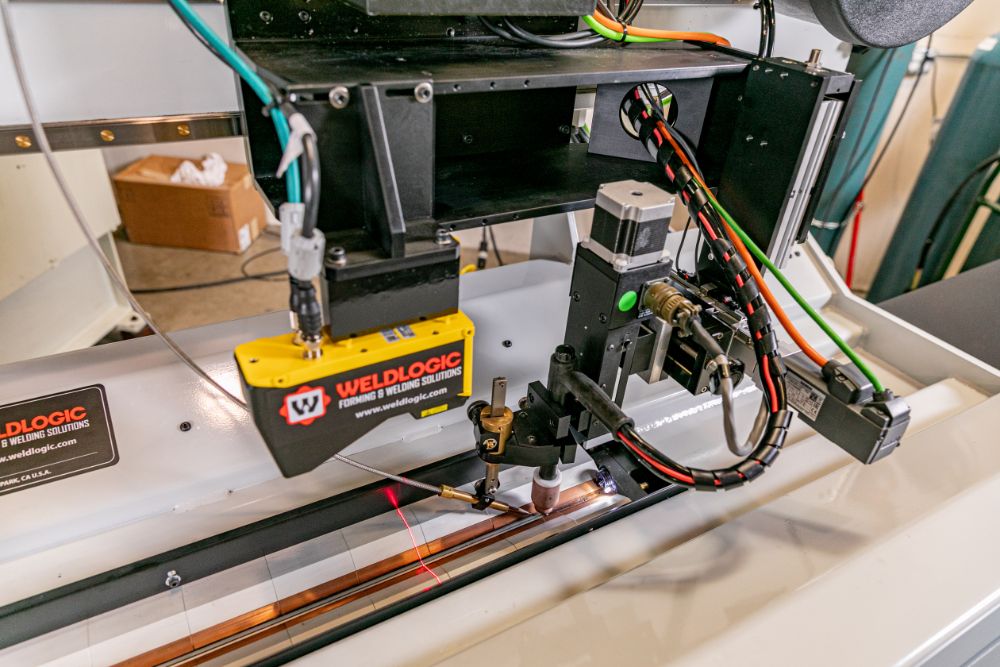

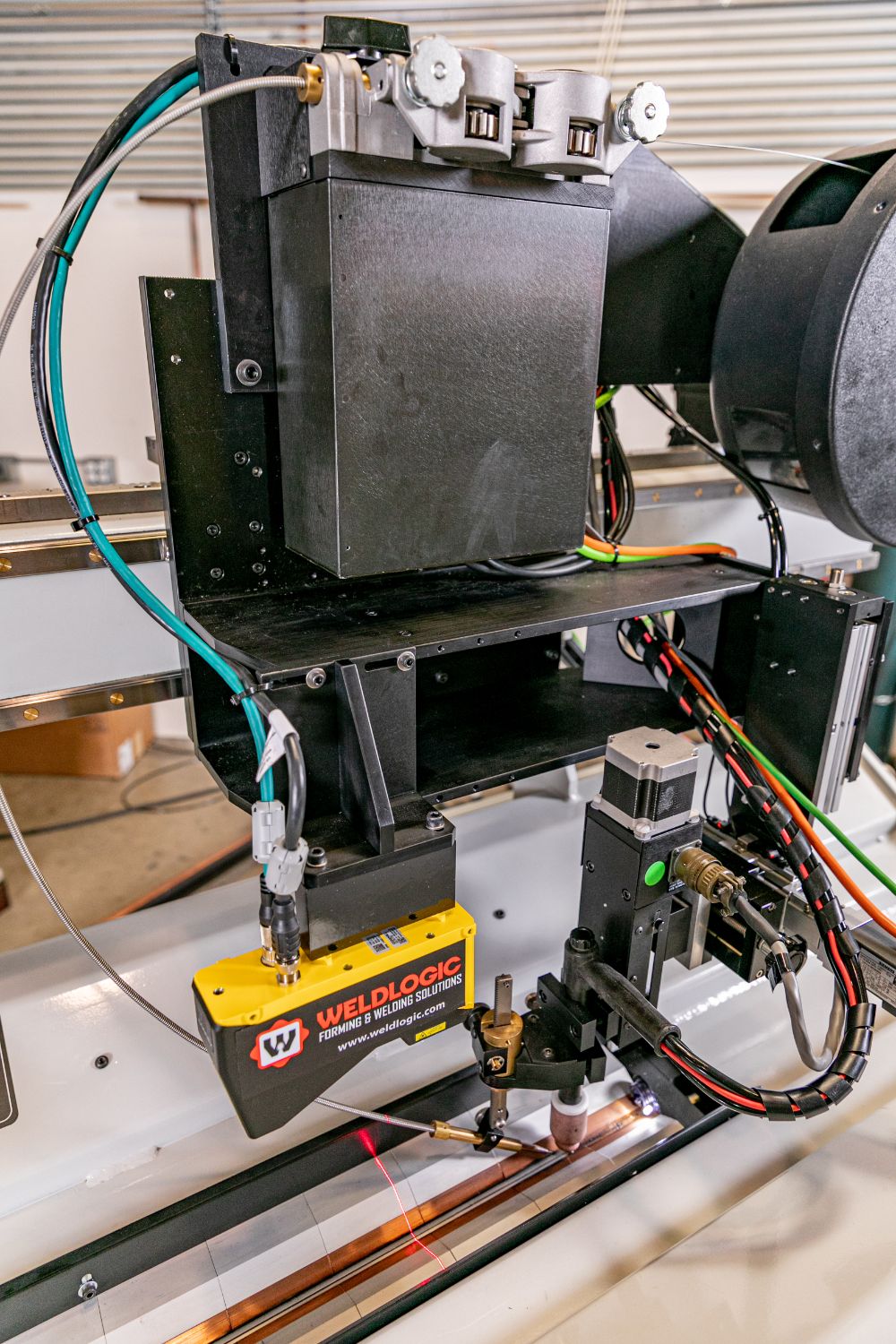

To improve weld quality, eliminate an operator steering the weld head from start to finish and free the operator up to perform other productive tasks during the welding process.

Solution:

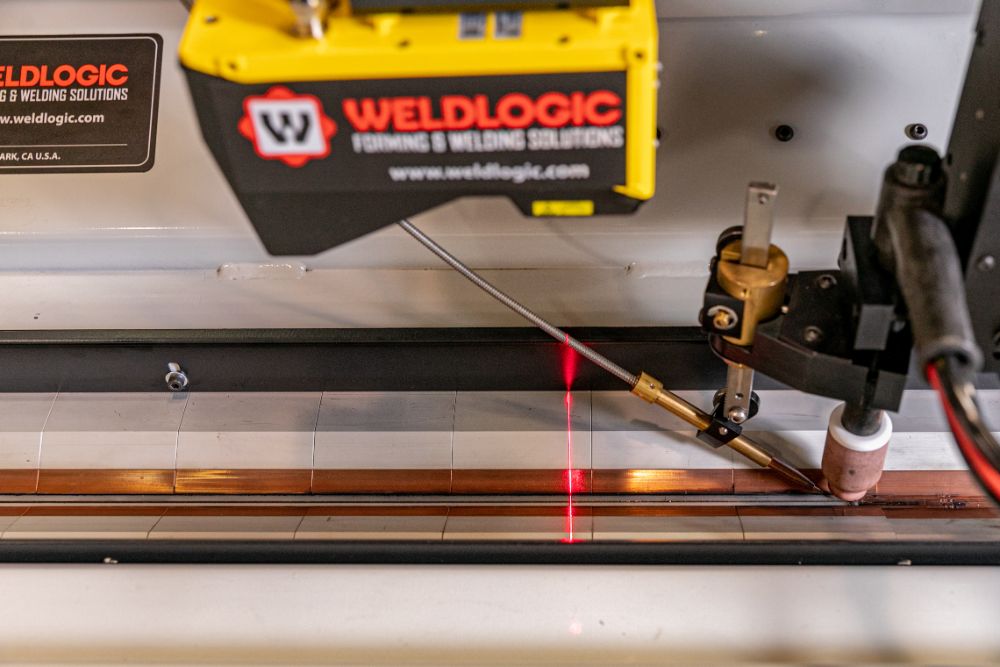

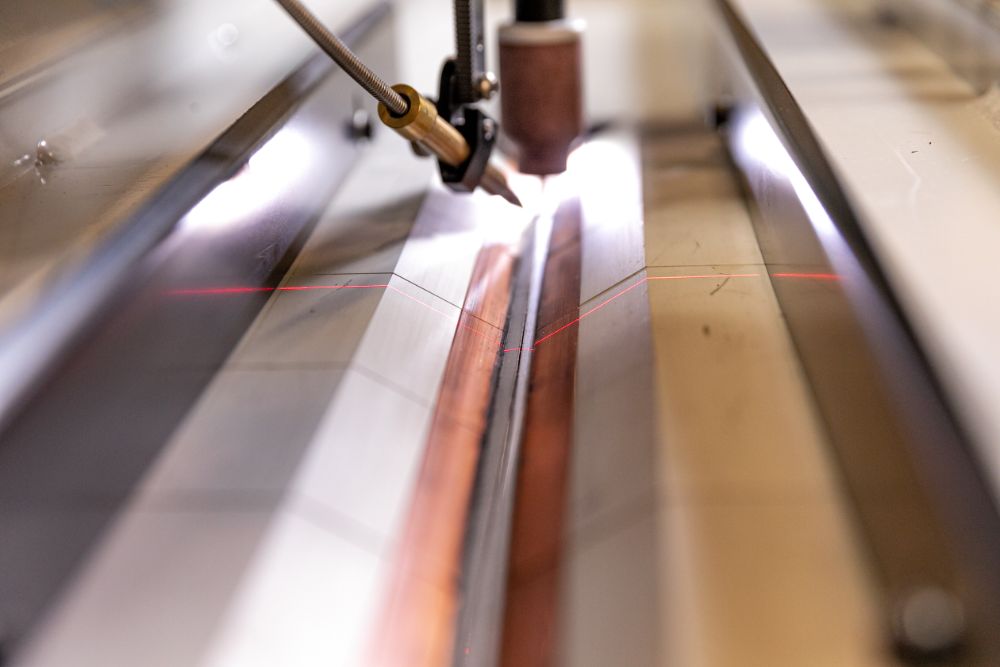

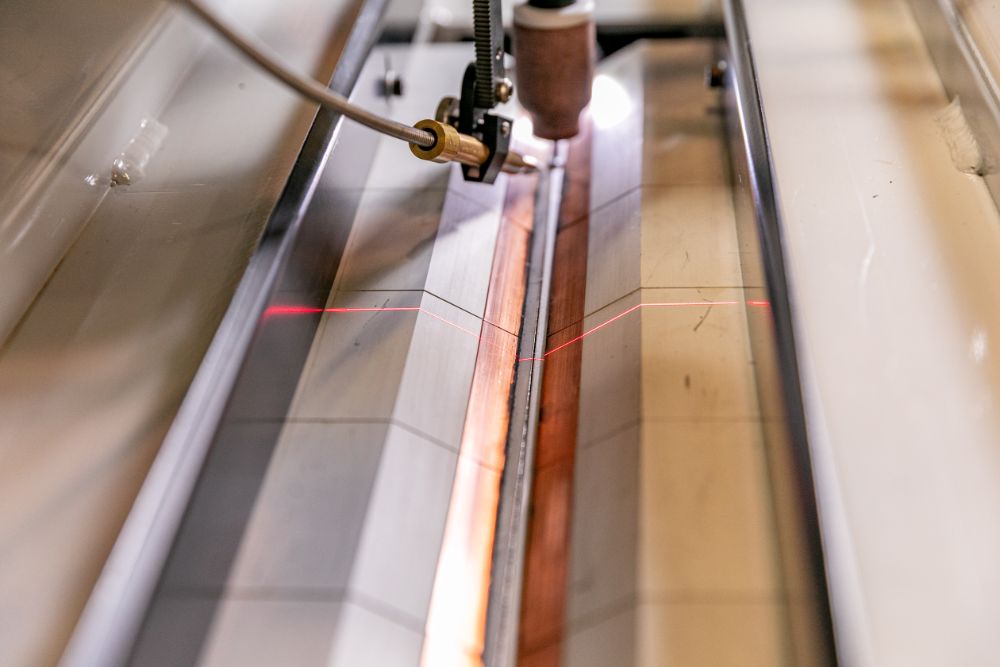

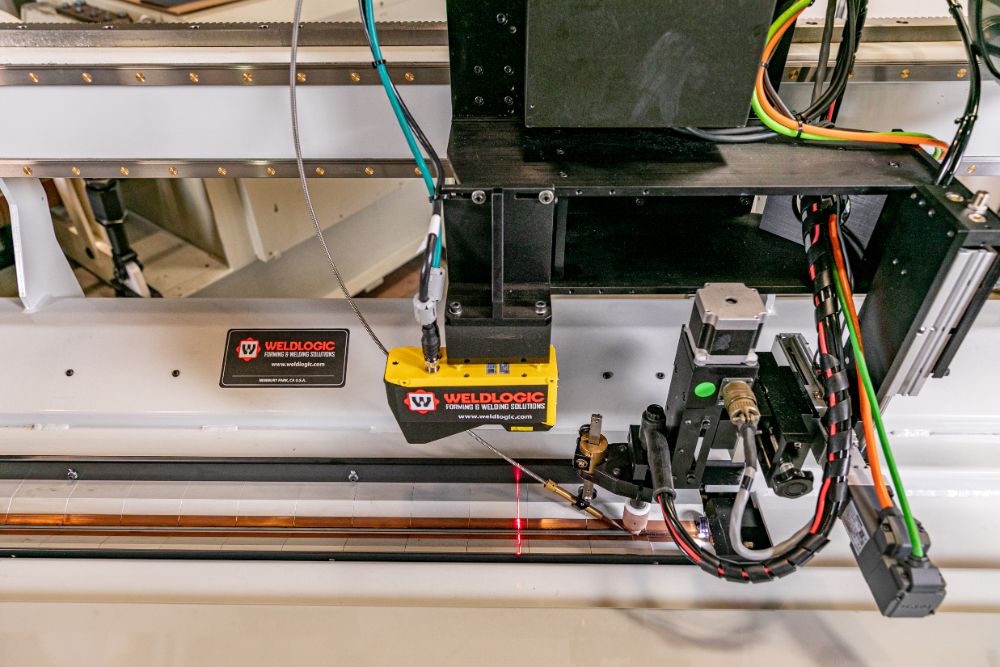

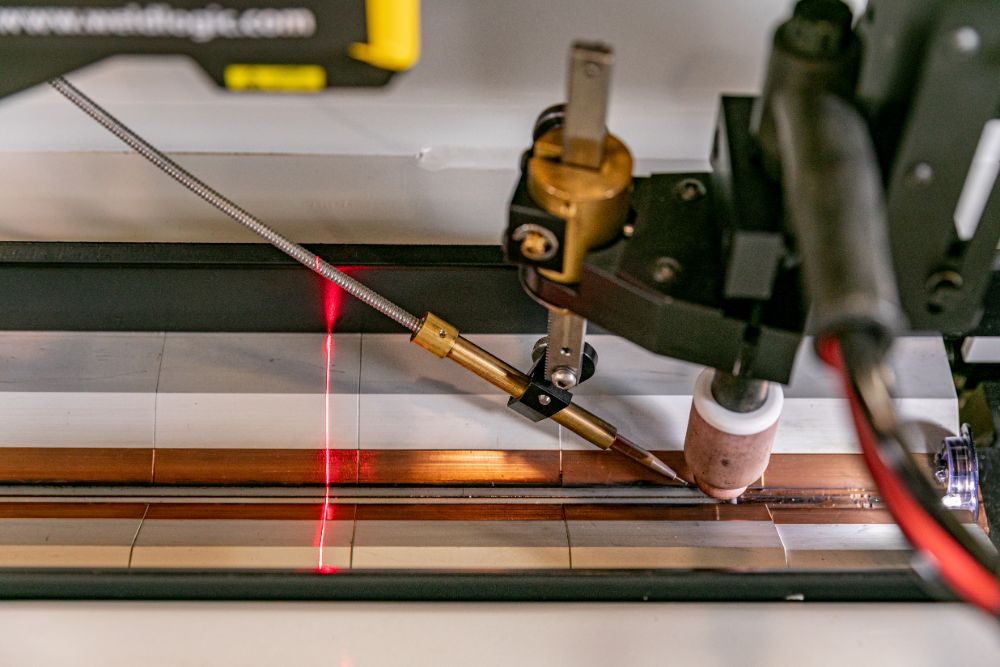

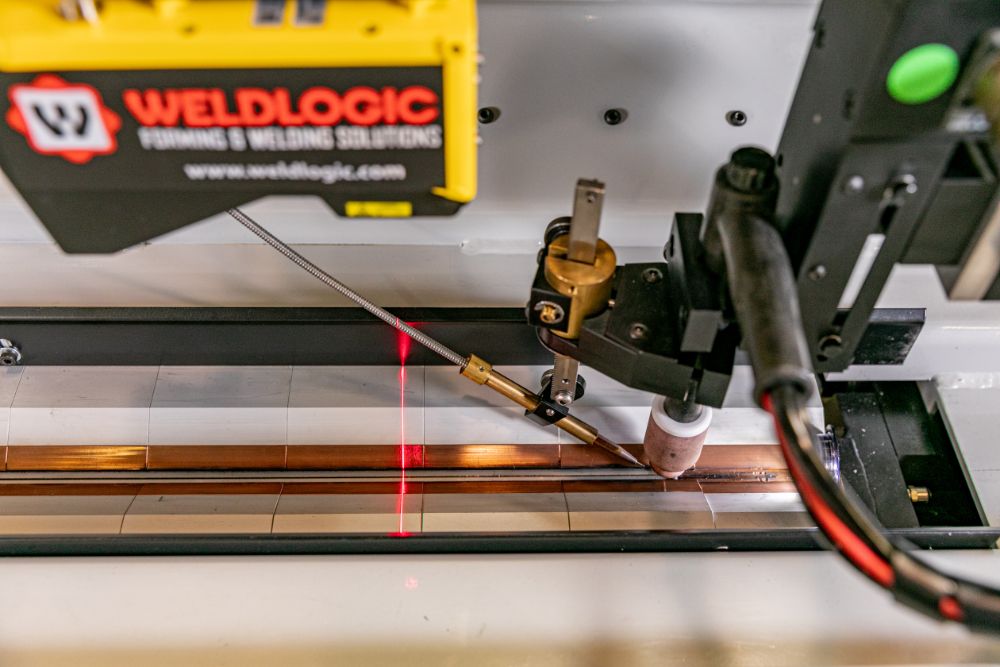

Weldlogic Engineering integrated a Dynamic Laser seam Tracker to enable the operator to load a tube quickly and press start and know the seam weld is made perfectly down the seam center on every tube.

· The 2-D tracker maintains a +/- .001” from seam center

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A

Ask our experts about your unique challenge

Previous Product

Corner / Box Welding System