Introduction

CHALLENGE

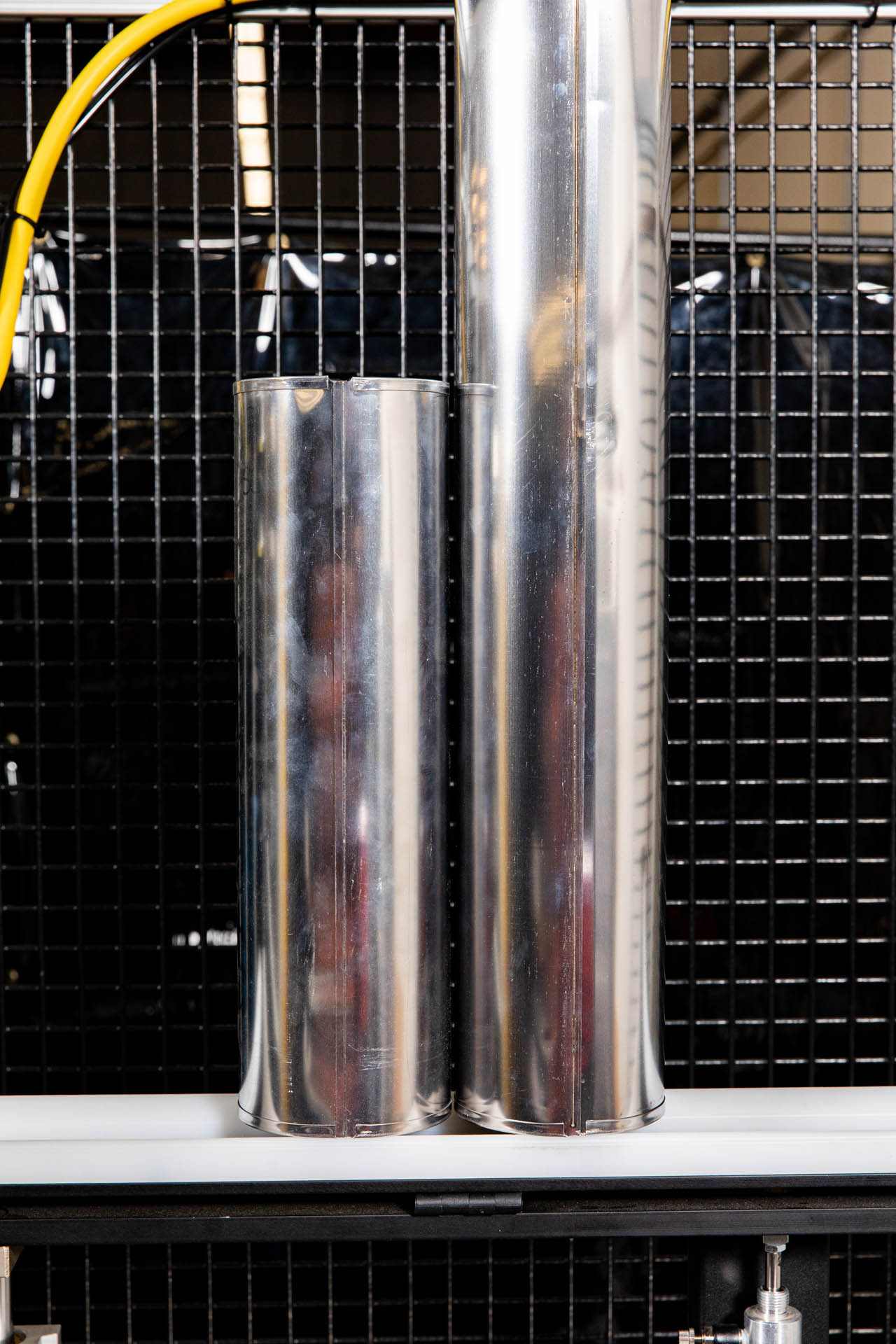

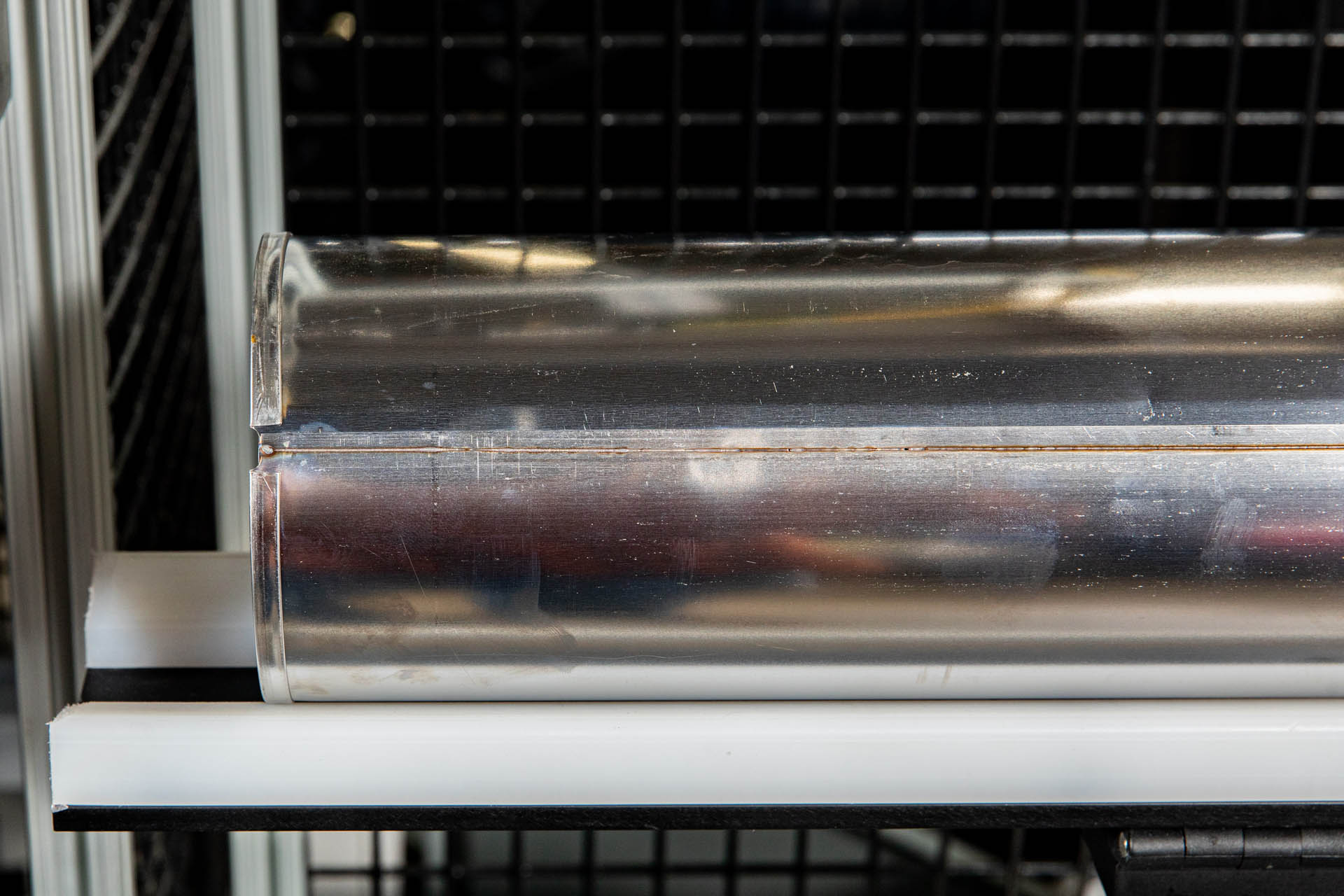

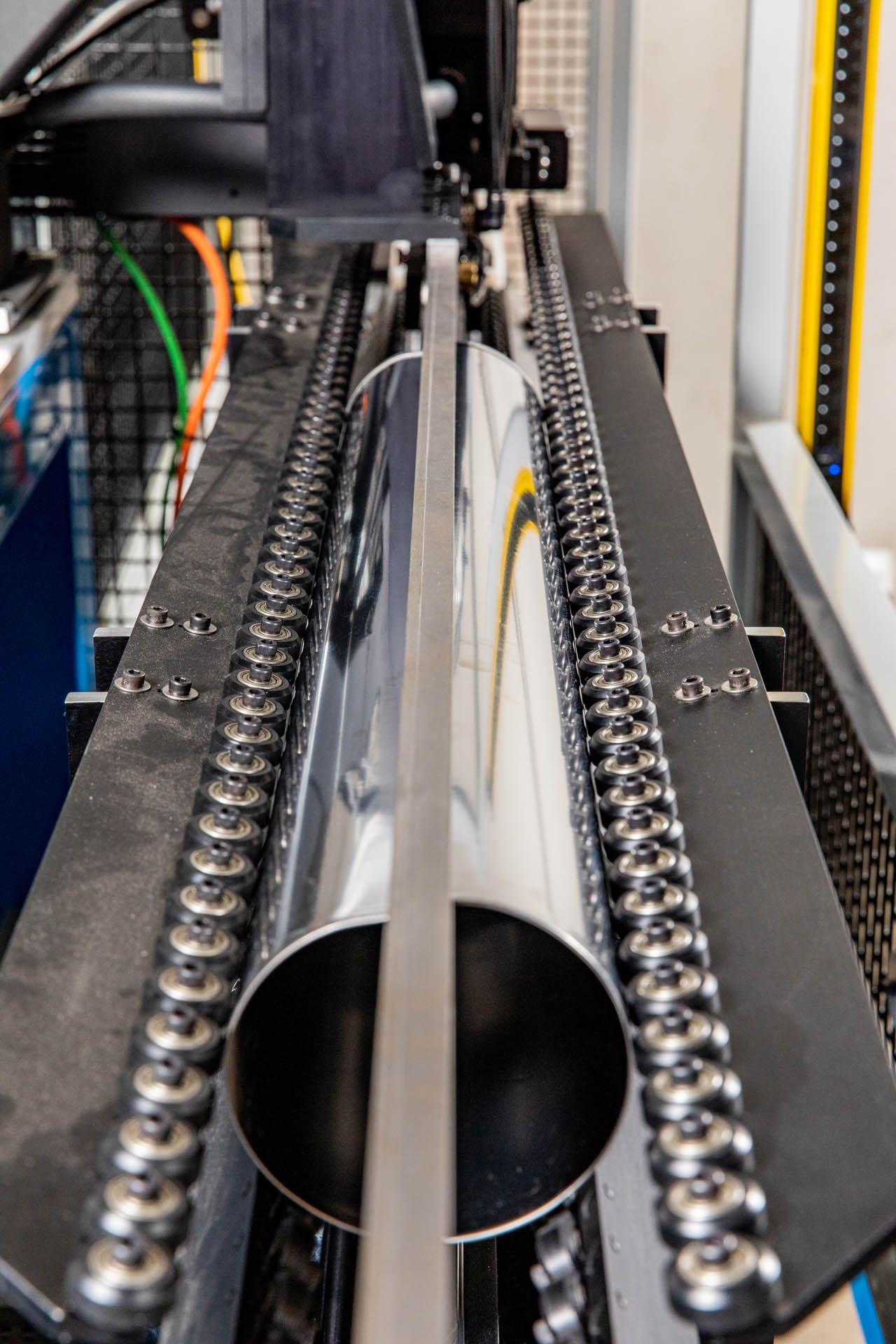

A fire place duct manufacturer needed to produce 180-250 duct seam welds per hour with integrity, end forming strength and low operator skill requirements. They need to run at a weld speed of 300 I.P.M. and require very low consumables to meet their goals.

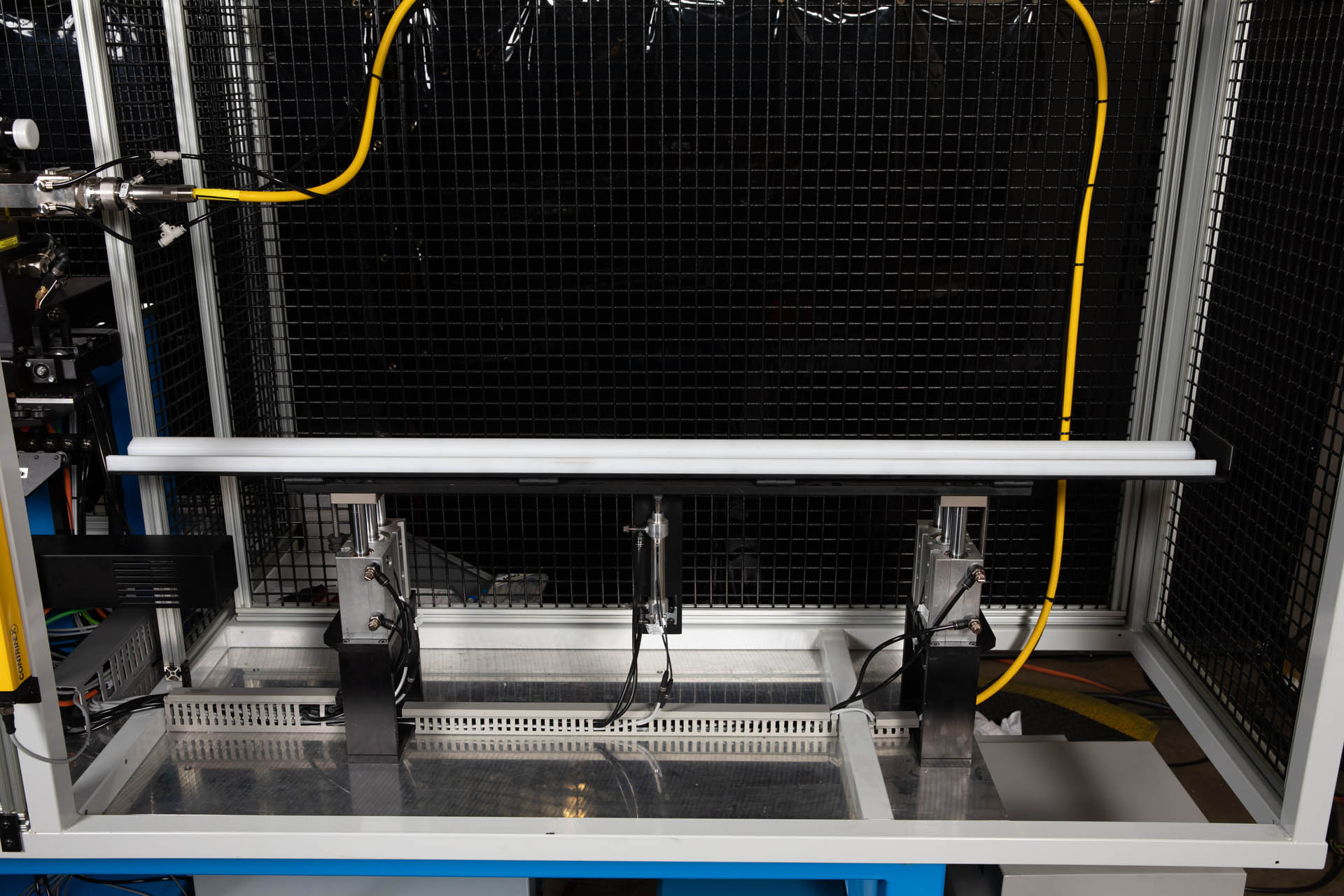

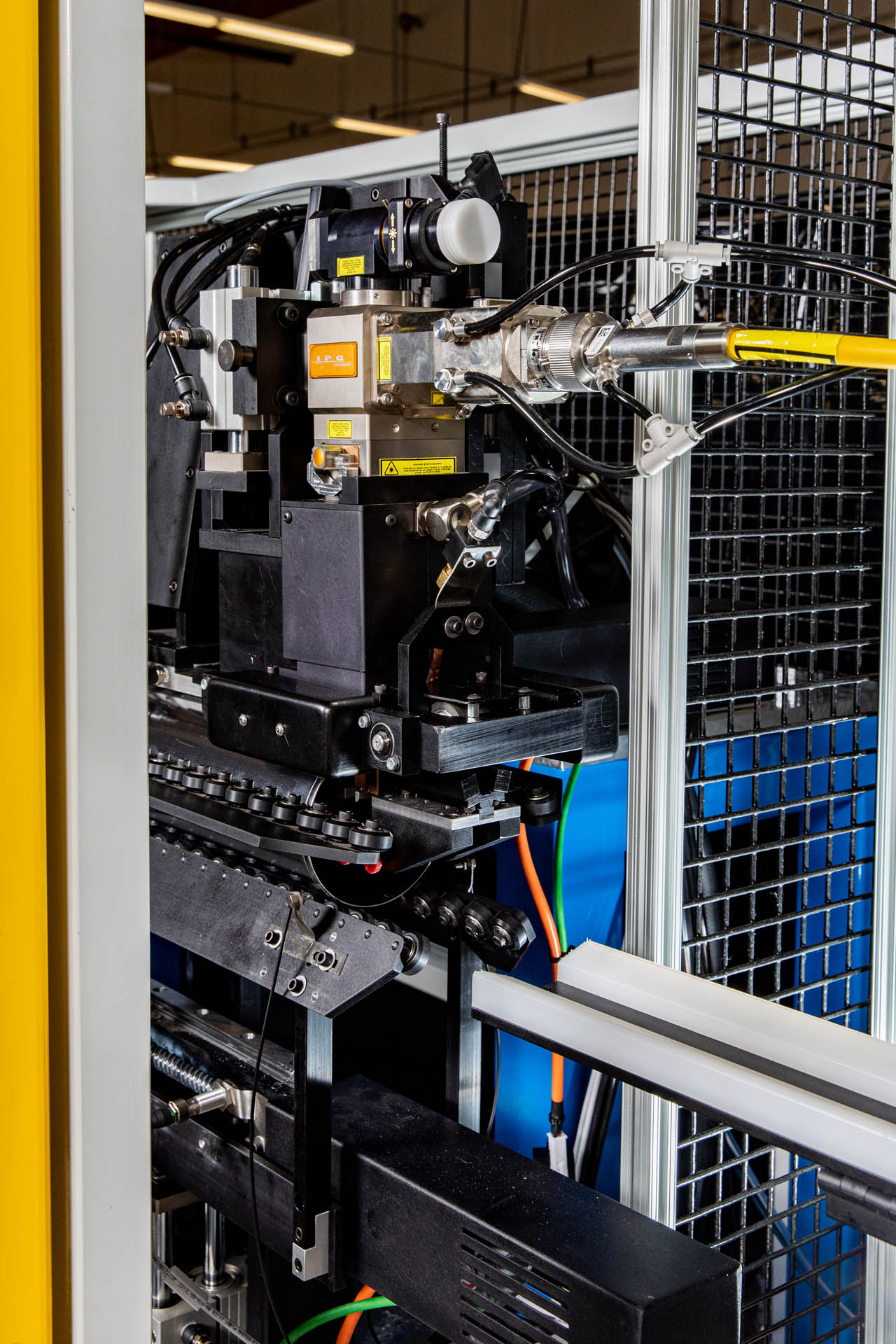

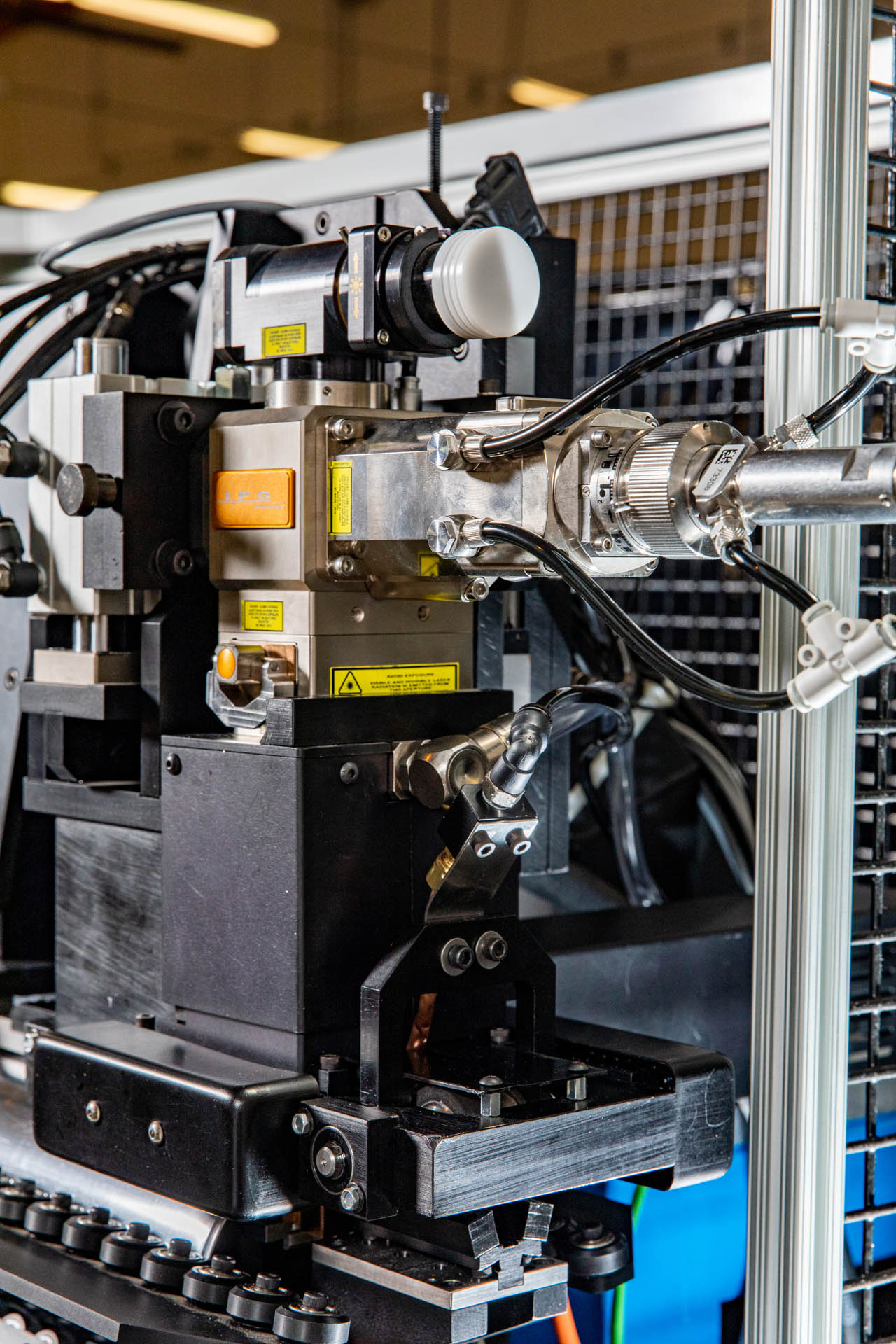

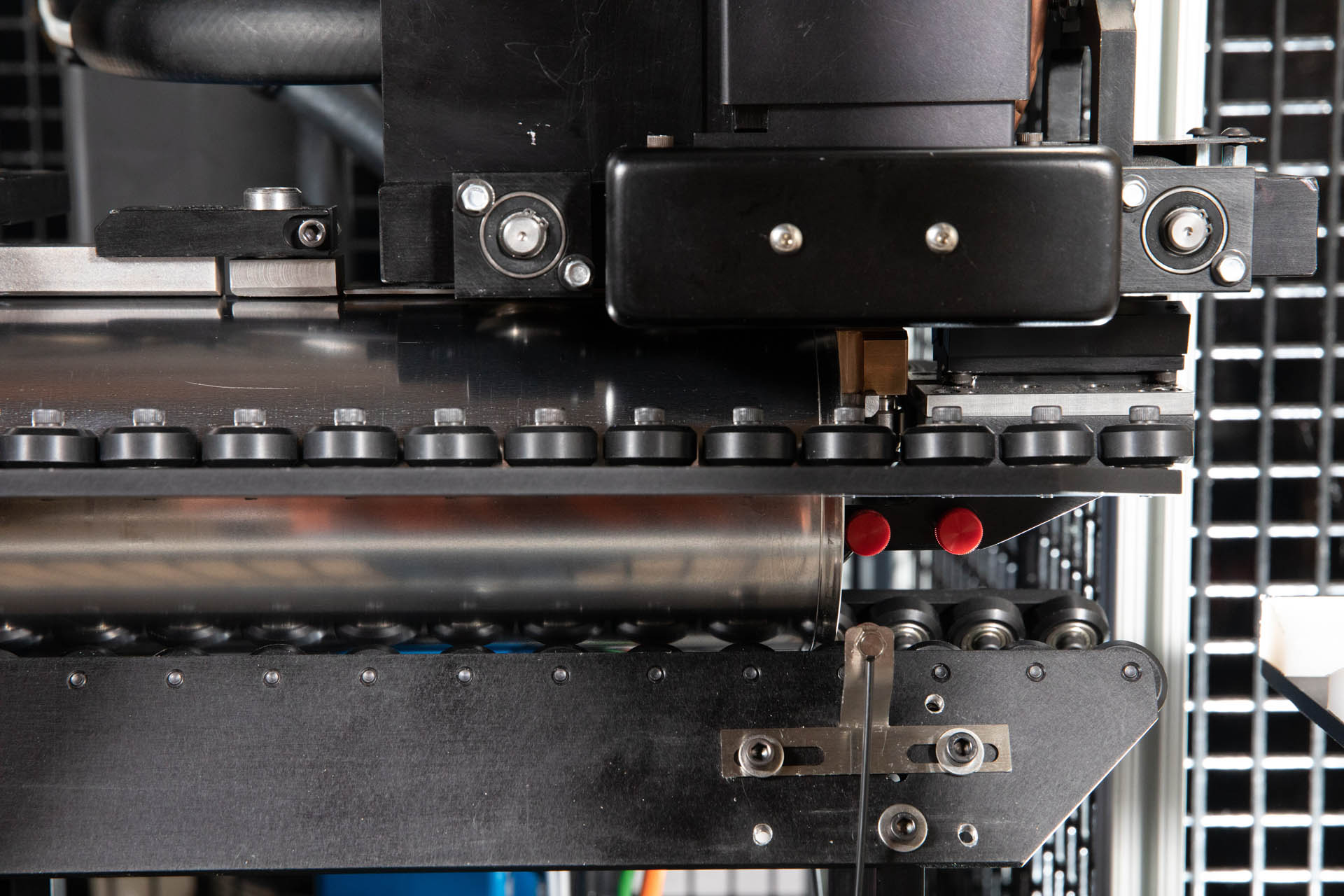

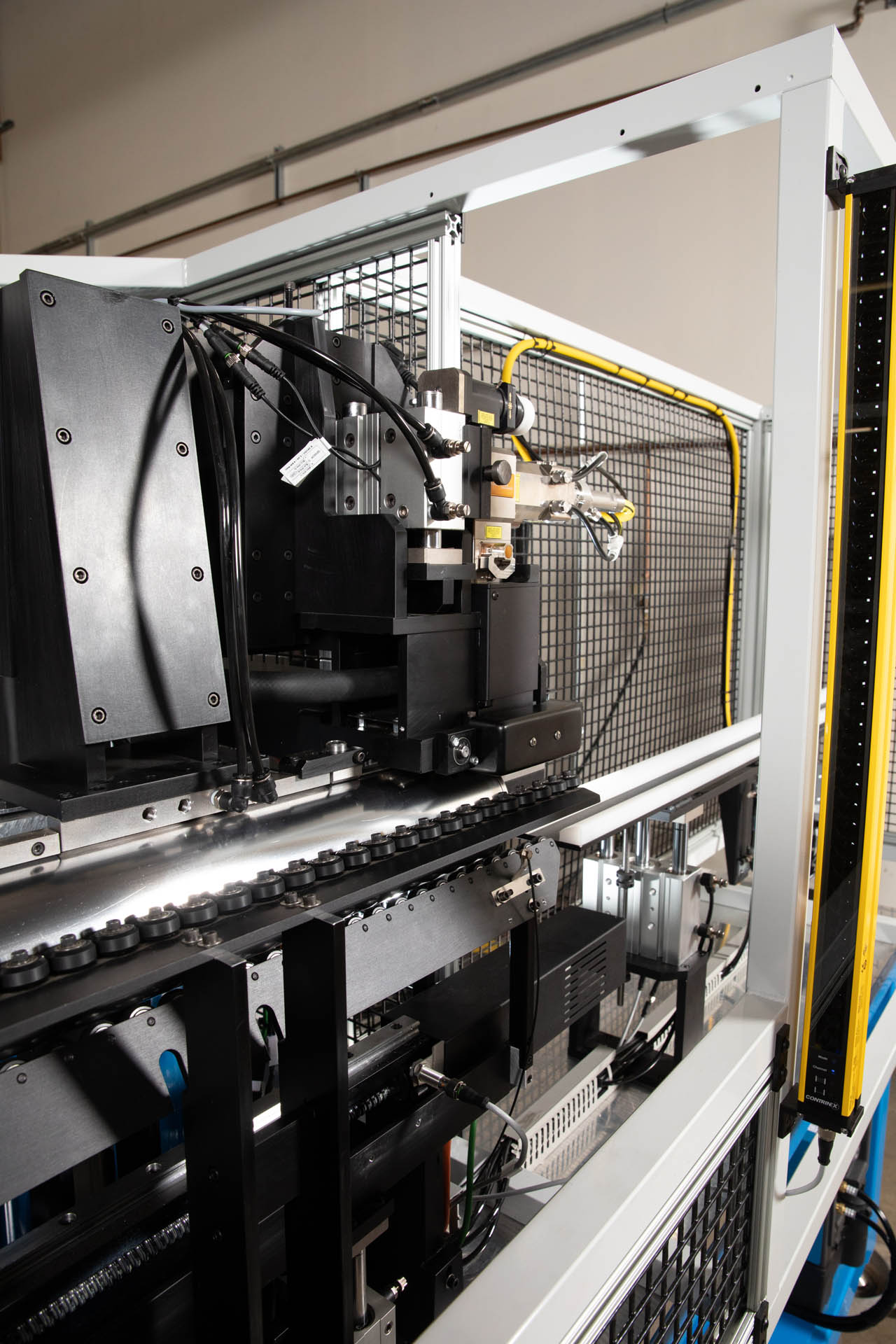

SOLUTION

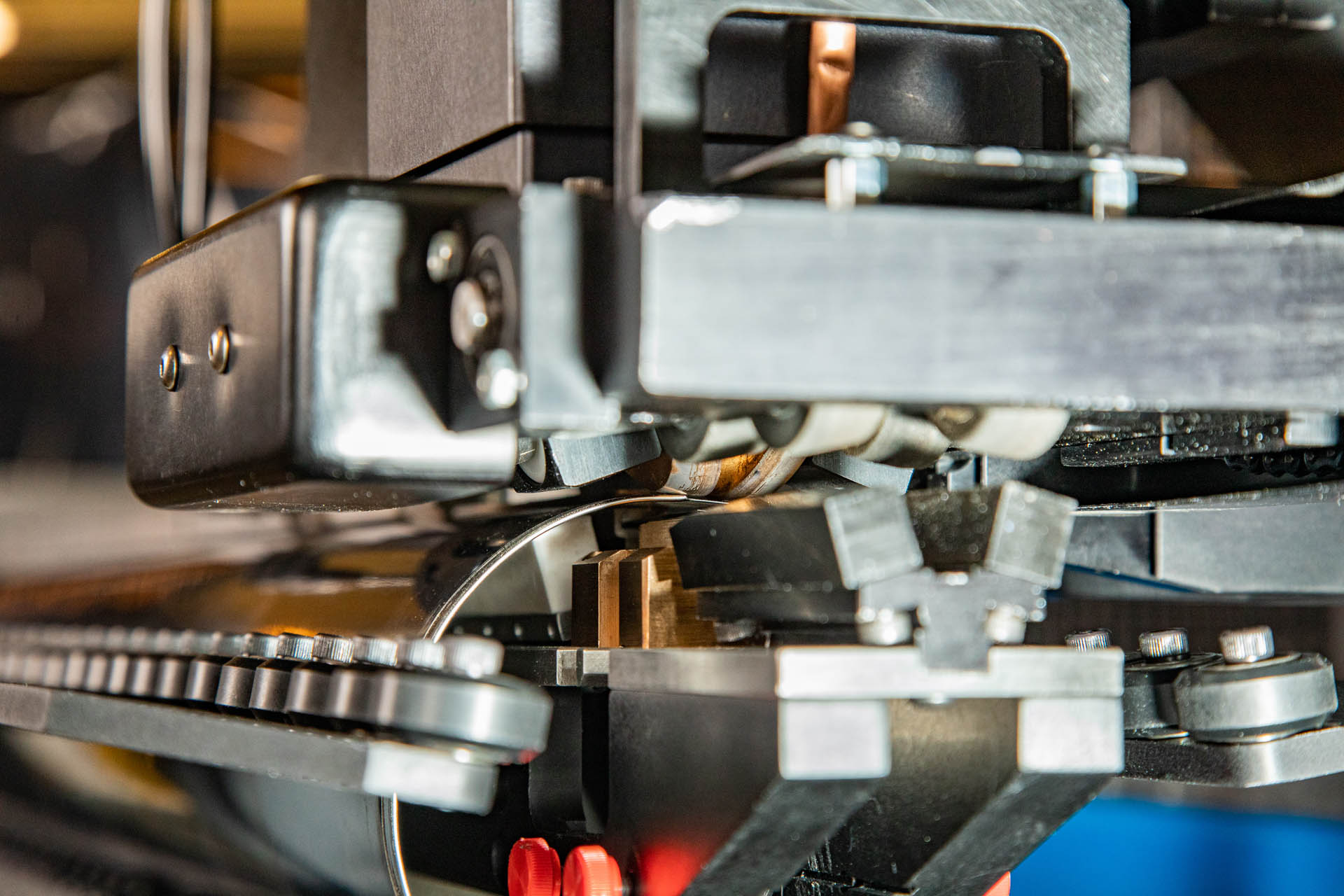

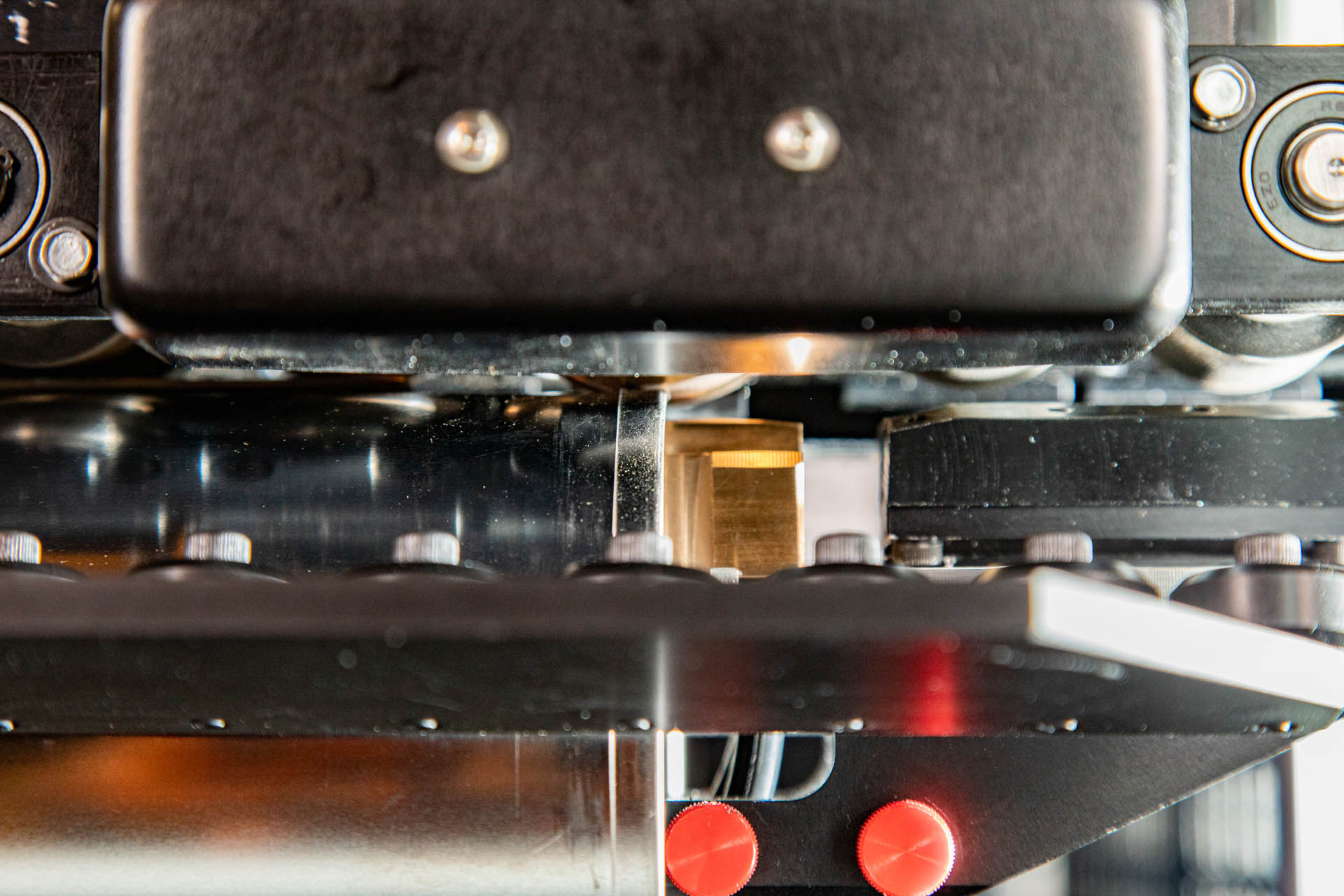

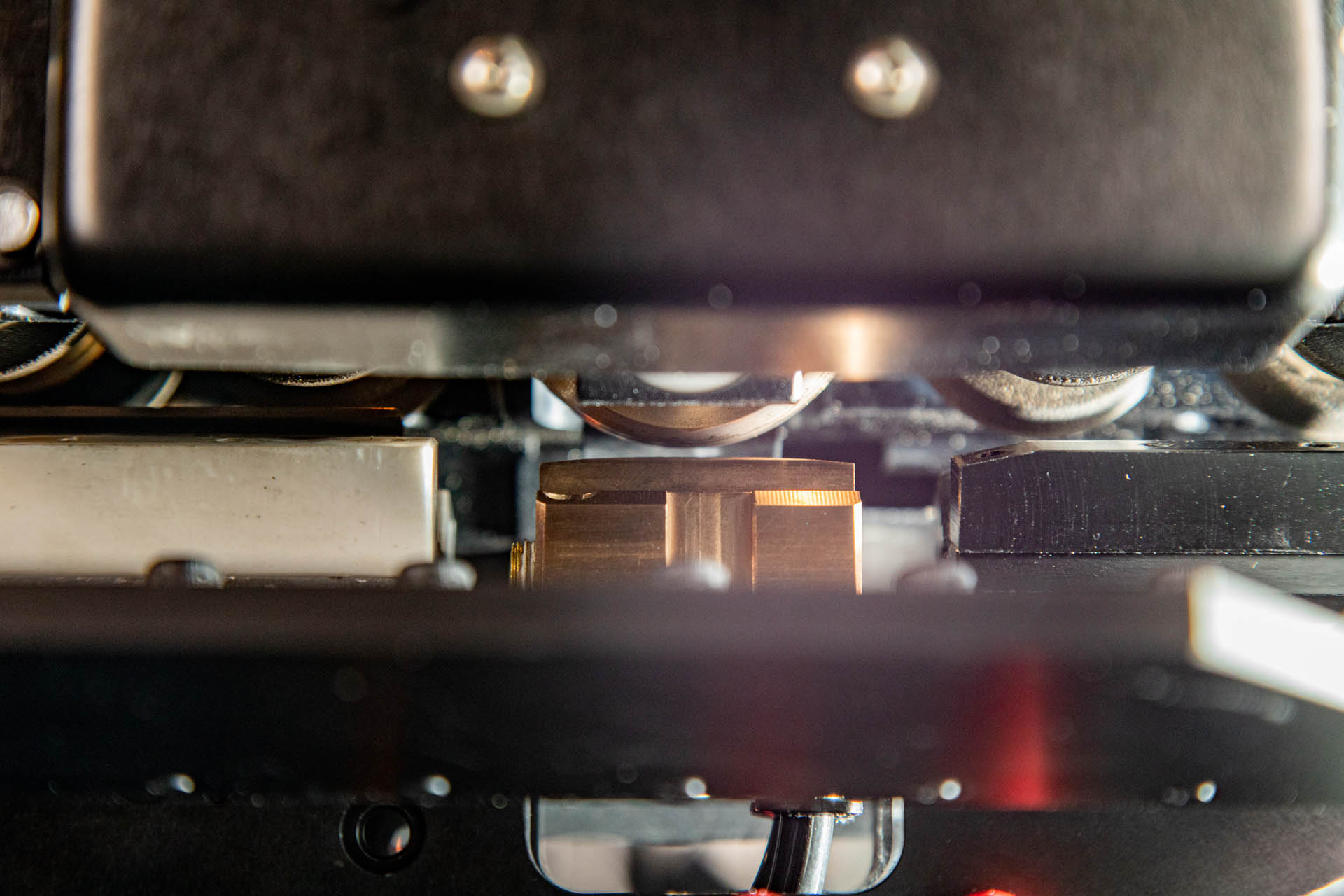

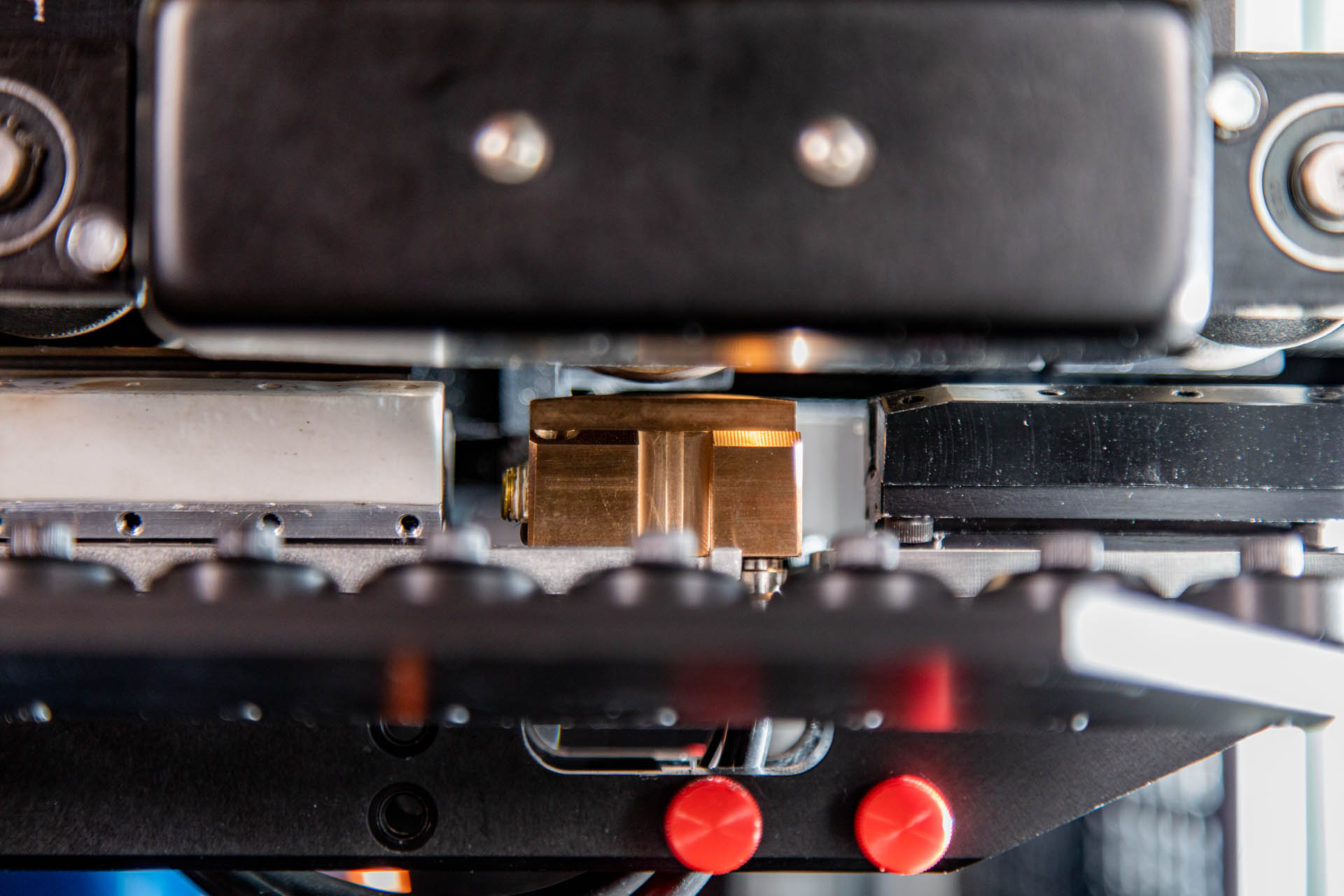

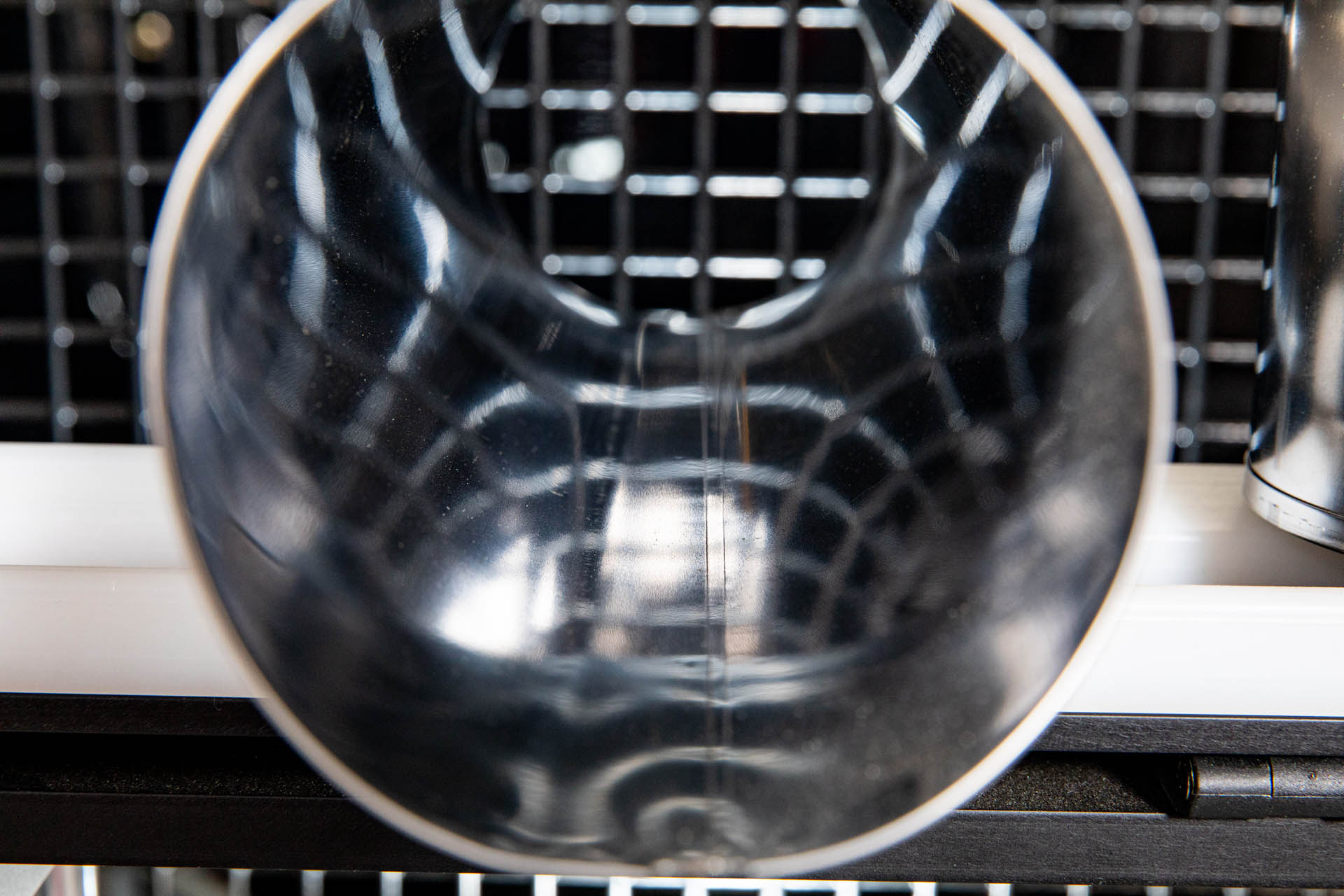

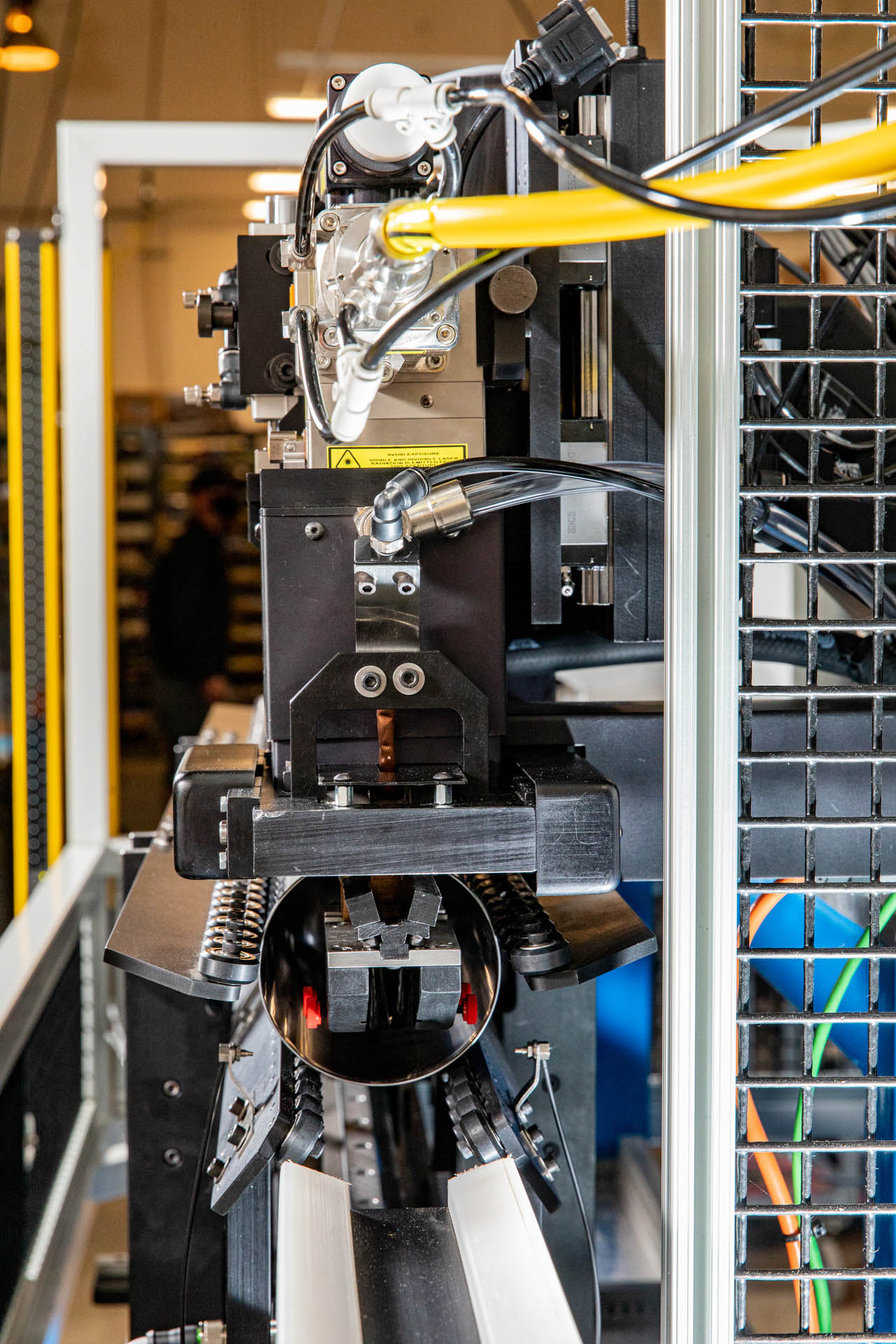

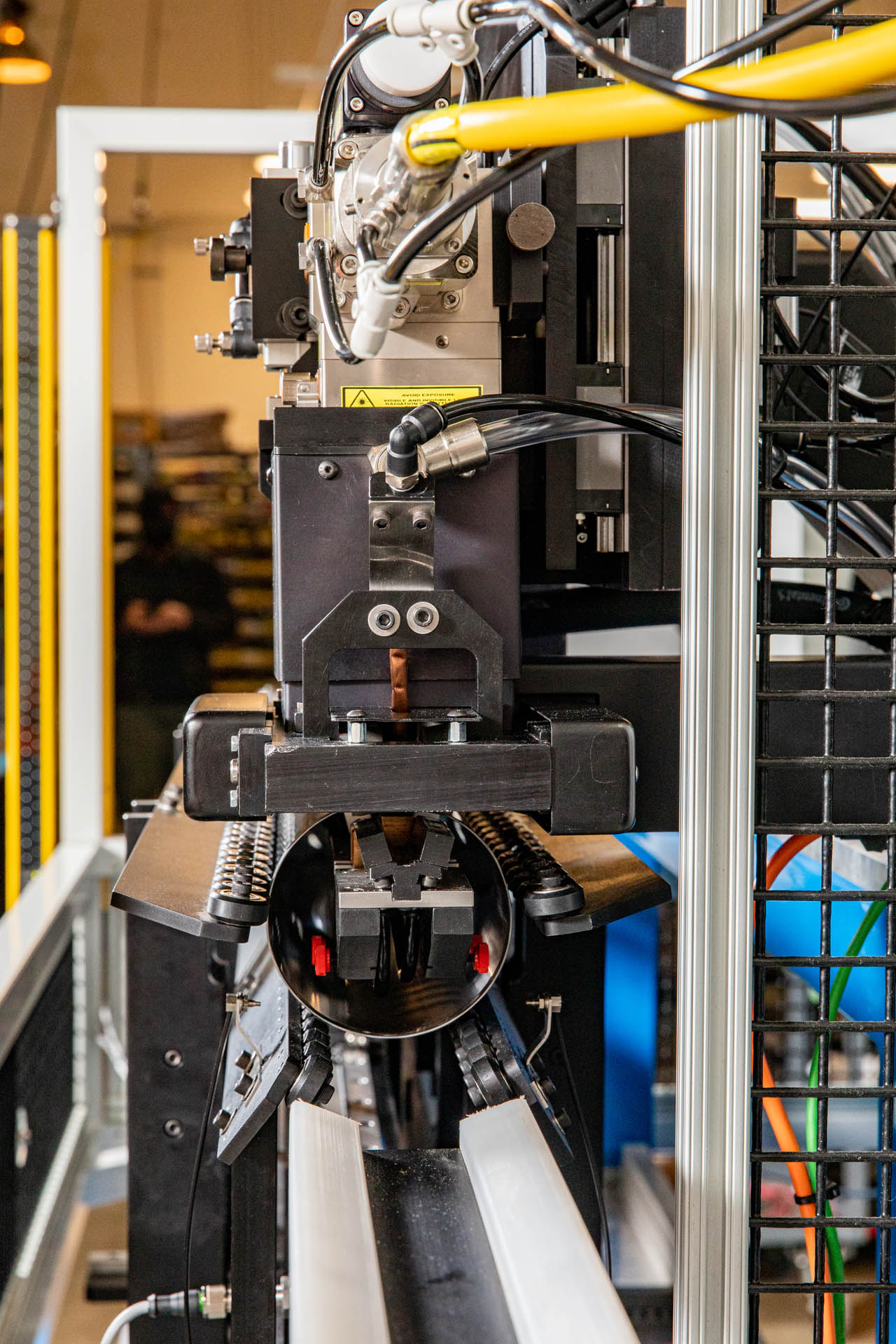

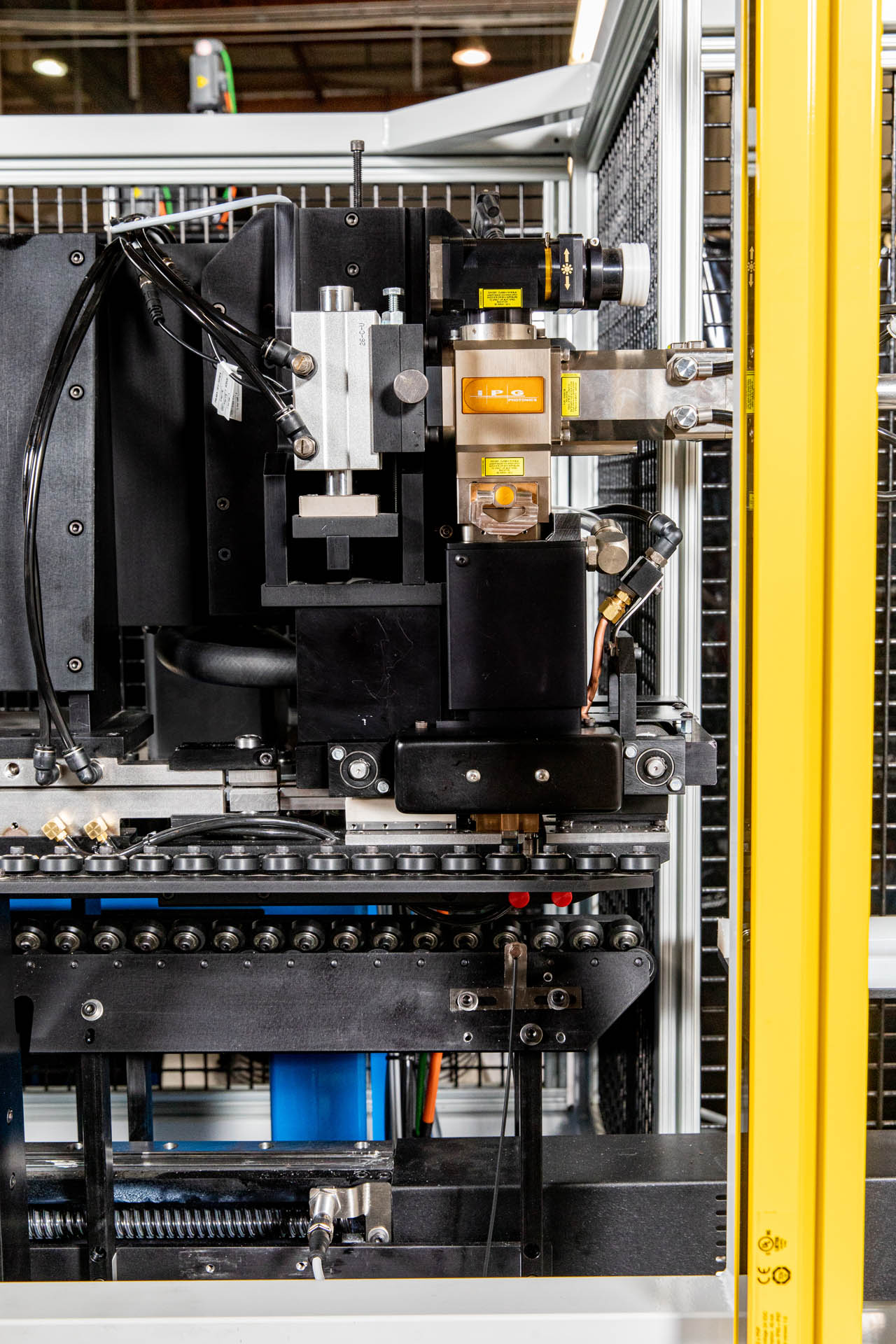

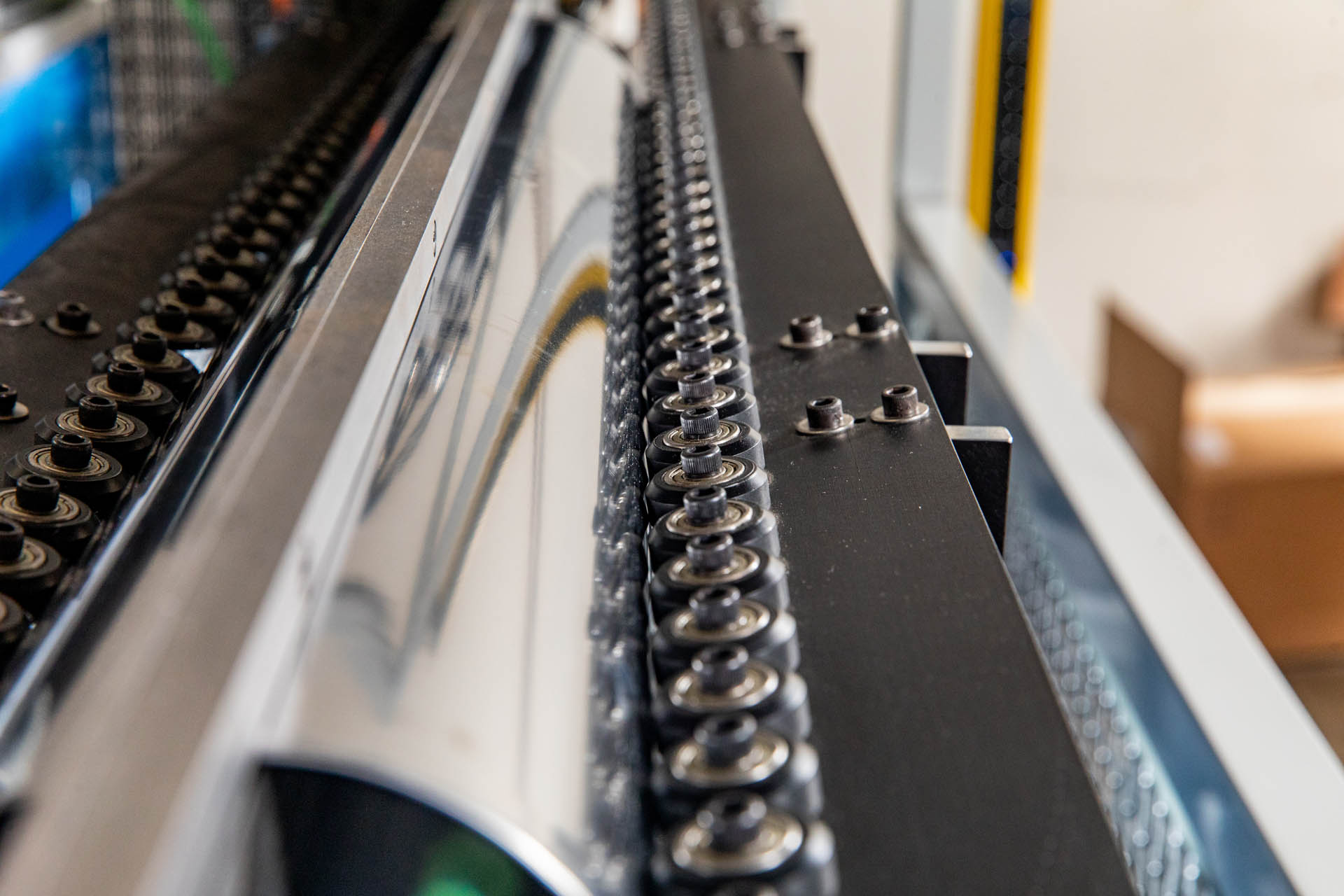

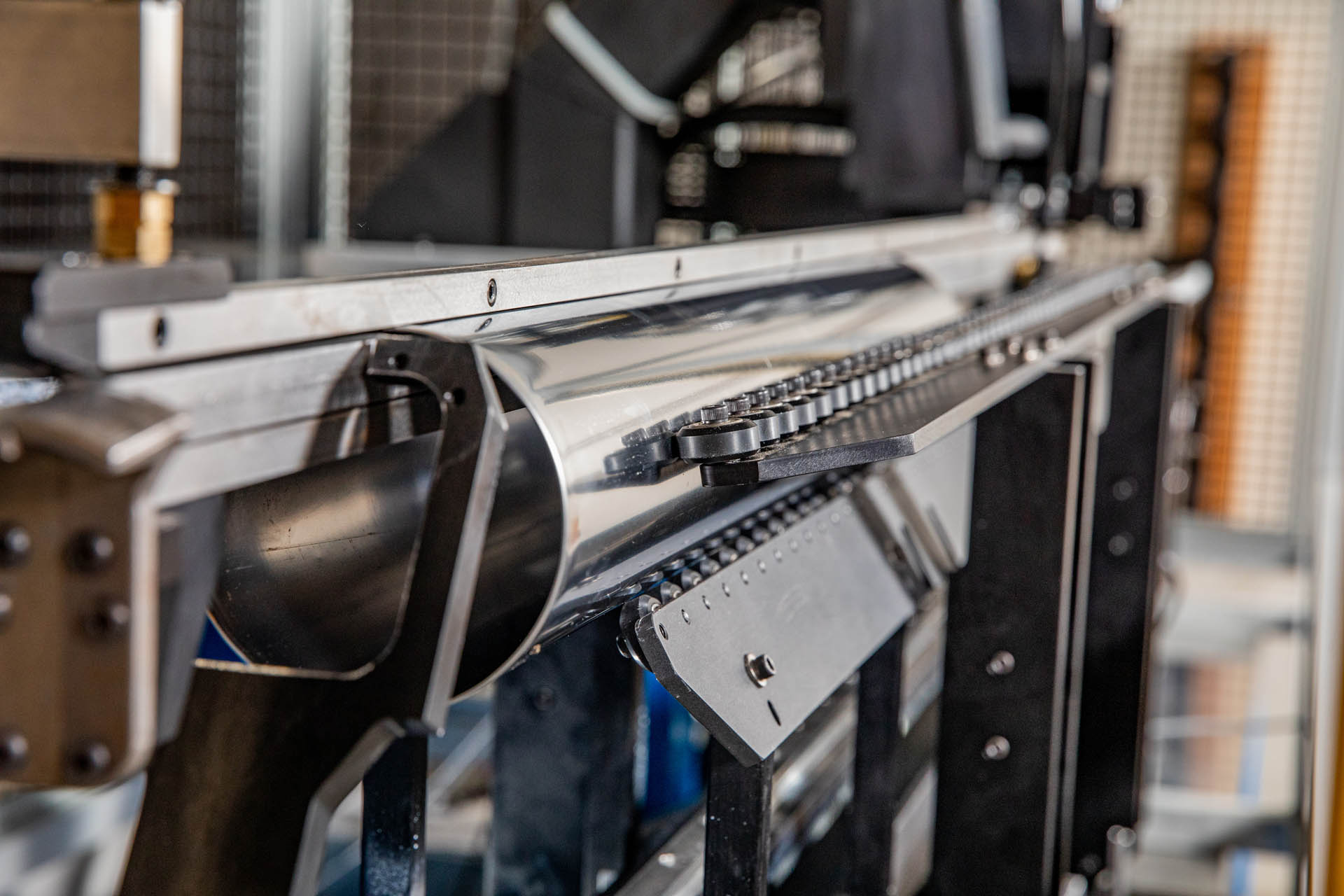

Weldlogic engineering needed to develop and validate the laser seam welds to meet the speed and quality required. A fiber laser was selected and engineering designed a pull through high speed laser seam welder to offer the high speed laser welding system required.

Video

Gallery

Features

N/A

Specifications

N/A

Applications

N/A

Ask our experts about your unique challenge

Previous Product

AWS-3 Axis G.T.A.W. Weld Cell