Introduction

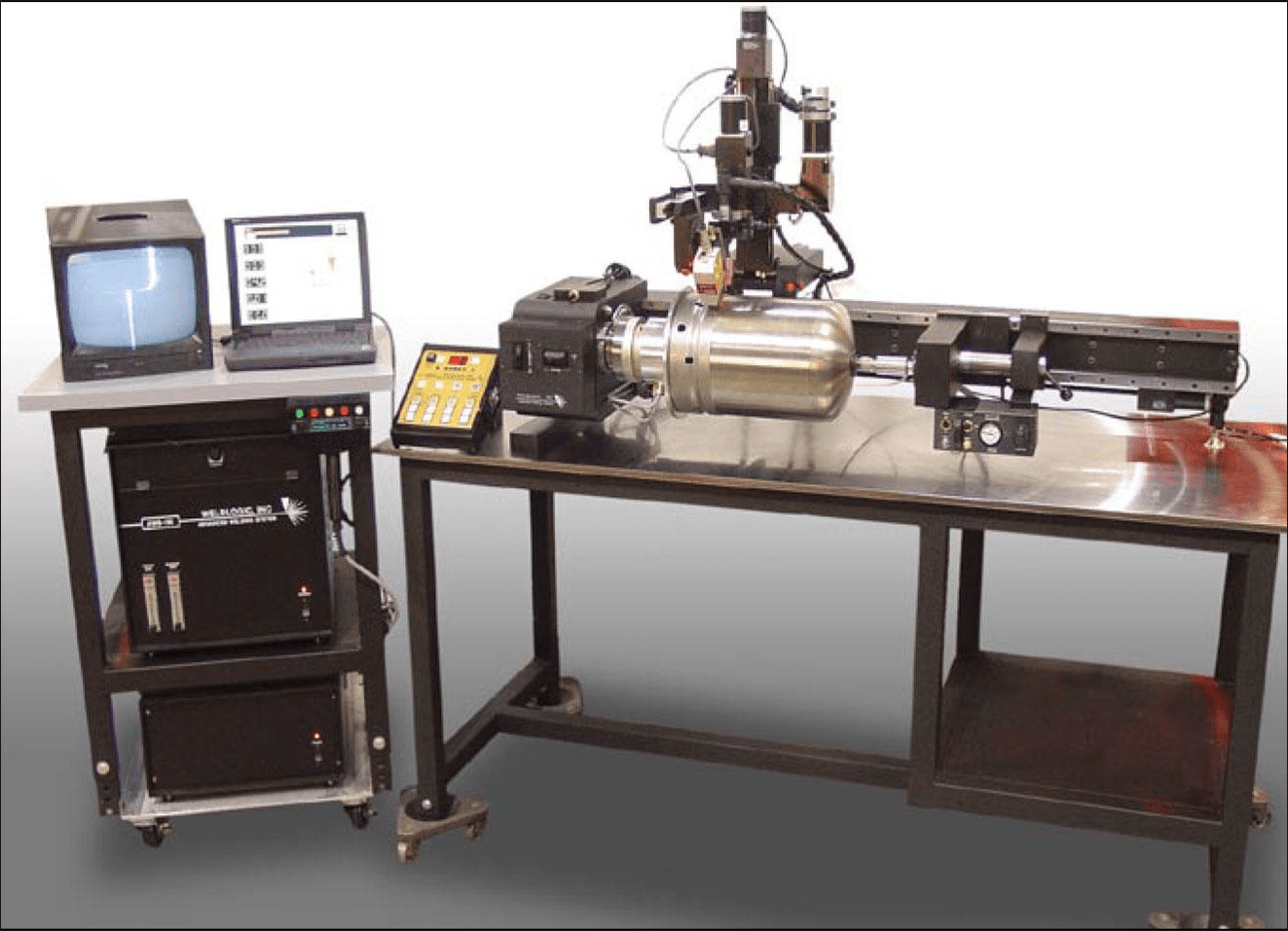

This AWS-300 / 6100 Advanced Welding System was manufactured to provide a fully Automatic Circumferential welding cell. The part purge time and multipass weld time could run up to 10 minutes per part. The customer required minimal labor content and 100% yield.

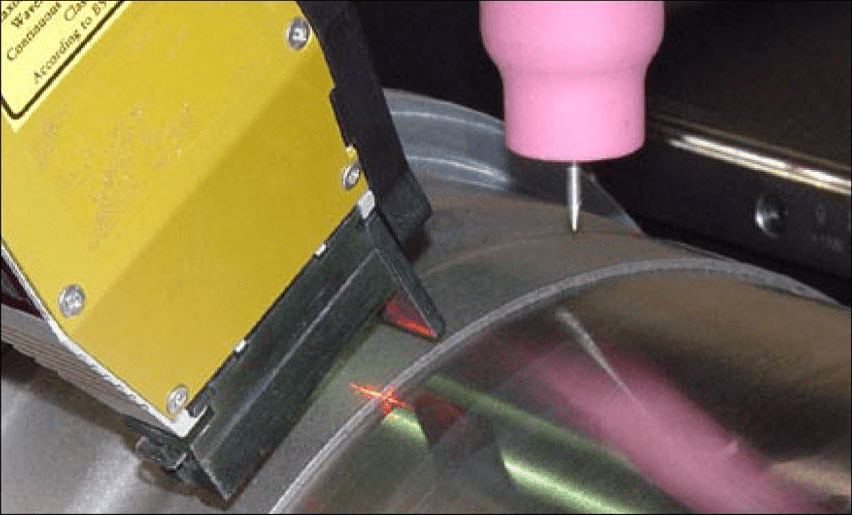

Weldlogic Engineers provided a fully integrated AWS-300 with quick purge and a Laser Seam Tracker to insure precise torch positioning over the weld seam and enable the operator to perform other tasks during the entire welding operation.

Video

Gallery

Features

- AWS-300 Advanced Welding System

- Arc Voltage Control

- PWL-15-36 Precision Welding Lathe

- Laser Seam Tracker / Monitor

- 2 Axis of Joy Stick Torch Positioning

- Live Center tail stock with Gas Purge

- Retractable Torch / Tail Stock – Air Actuated

- 3 Axis of Laser Tracking Adjustment

- Horizontal / Verticle Lathe Positioning

Specifications

N/A

Applications

- 304 / 316 S.S. Pressure Vessel Welding

Industry:

- Pharmaceutical, Bio Tech, Semi-Conductor

Requirements:

- X-ray clear, Low distortion, Full penetration, Operator free operation

Ask our experts about your unique challenge

Previous Product

AWS-150 / 6100 CNC Saddle Welding System