[Engineering Solutions] Automatic G.T.A.W. Welding Made Easy

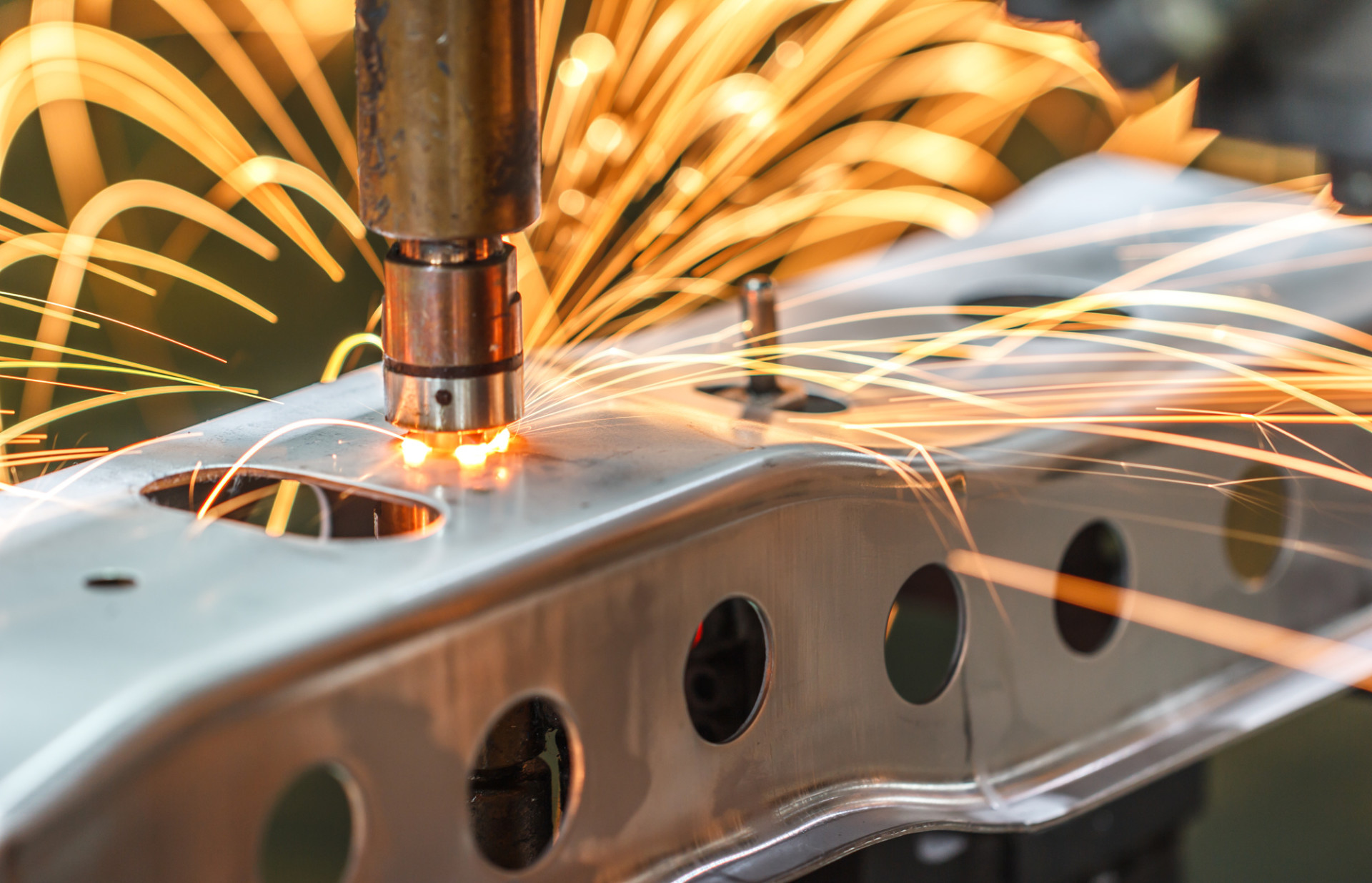

Weldlogic Engineering Team has recently installed a fully automatic custom AWS-400 A.C./D.C. Welding System for precision Cladding and the welding of Aluminum end caps.

The welding which was being done manually was time consuming and produced welds that were inconsistent and often failed final inspection.

The custom built machine comprising of Weldlogic AWS -400 A.C./D.C. power supply, wire feed, arc distance control and PWL -24-36 custom precision welding lathe has improved production times and dramatically improved weld quality with significant cost savings.

Working closely with the customer a number of weld schedules have been developed and qualified , these weld schedules which are stored in the machine can be easily accessed by the operator and quickly downloaded to the welder for every part configuration.

One of the most interesting features was the ability for the customer to select and control the various A.C. Wave shapes used for welding Aluminum and its alloys and easily converting to D.C. to weld high nickel alloys.

CONTACT WELDLOGIC ENGINEERING FOR YOUR FORMING OR WELDING SOLUTION.