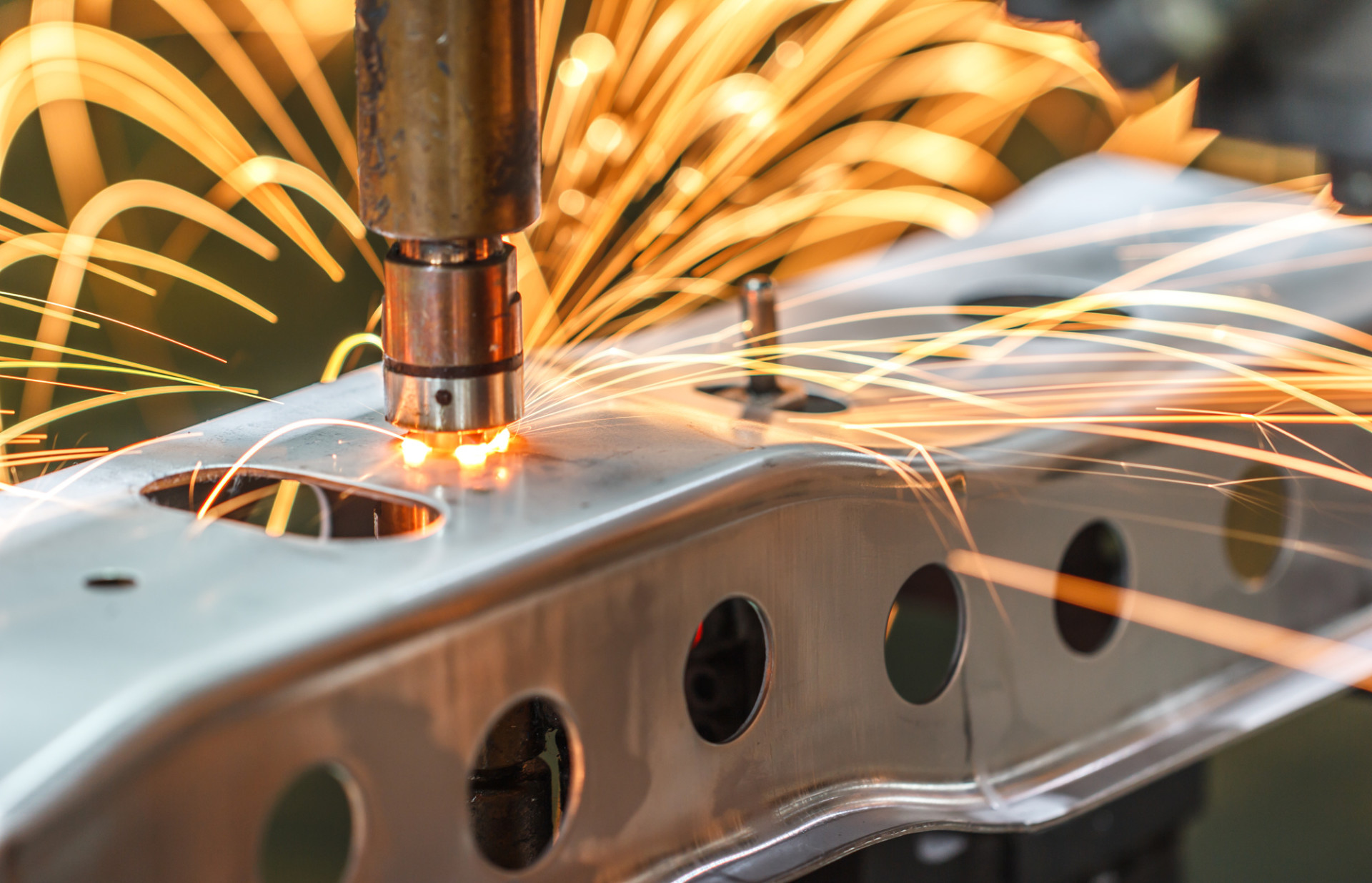

Boosting Efficiency and ROI: The Advantages of Automatic Welding & Forming

Automated systems have changed the way the manufacturing industry produces work. In order for businesses to stay ahead of the competition, they have to stay on top.

One way to do so is by looking into automatic welding & forming. If you don’t yet know the advantages, this article is for you.

Let’s get started.

See an Increase in Productivity

One thing automation has brought to the manufacturing industry is an increase in productivity. This increase is what every business wants to see in order to keep up with the work demands and see profits.

With the use of automatic welding & forming, businesses can ensure a steady level of productivity each day. Automatic welding & forming can be three to five times faster.

The Quality of the Work

A concern in the industry has always been the quality of the work.

The use of a automatic welding & forming allows for a more precise welding angle. Therefore, it allows for the quality of the work to be more precise and consistent.

The reputation of the business depends highly on the quality of the work produced.

Safer for Everyone

With the help of automatic welders & forming systems, the workplace has become a safer place. Safety risks for employees include electric shock, exposure to fumes, and even burns.

Robotic welding can help save the lives of many employees and reduce the risk of accidents in the workplace.

Allows More Flexibility

Utilizing automatic welding & forming systems allows for more production flexibility. Manual welding requires more steps and more parts need to be swapped out in order to accomplish each production run.

Lower Production Costs

Lower production costs mean a higher ROI. Automatic welding & forming not only improves the quality of the work, but it also reduces the initial production cost.

This cuts back on energy consumption, materials, and consumable costs.

Reduces Weld Distortion

It’s a known fact in the manufacturing industry that there has to be room for human error.

But in the case of automatic welding & forming, the gap is not as wide. Automated systems reduces weld distortion.

This happens when the weld metal and the metal base contract and expand during the expansion and contraction process.

Automatic welding & forming decreases the number of weld passes and completes the process faster.

Why Automated Welding & Forming Works: The Bottom Line

Automatic welding & forming allows for a safer workplace, work consistency, quality of work, and lower production costs. There are many benefits to automated systems.

Have more questions about how automated manufacturing works? Stop by and ask the experts. They can help you find the product for your business.

![Featured image for “[Engineering Solutions] Automatic G.T.A.W. Welding Made Easy”](https://weldlogic.com/wp-content/uploads/2018/08/IMG_0946-1.jpg)