Lessons In Laser: A Brief Guide to Modern Laser Welding

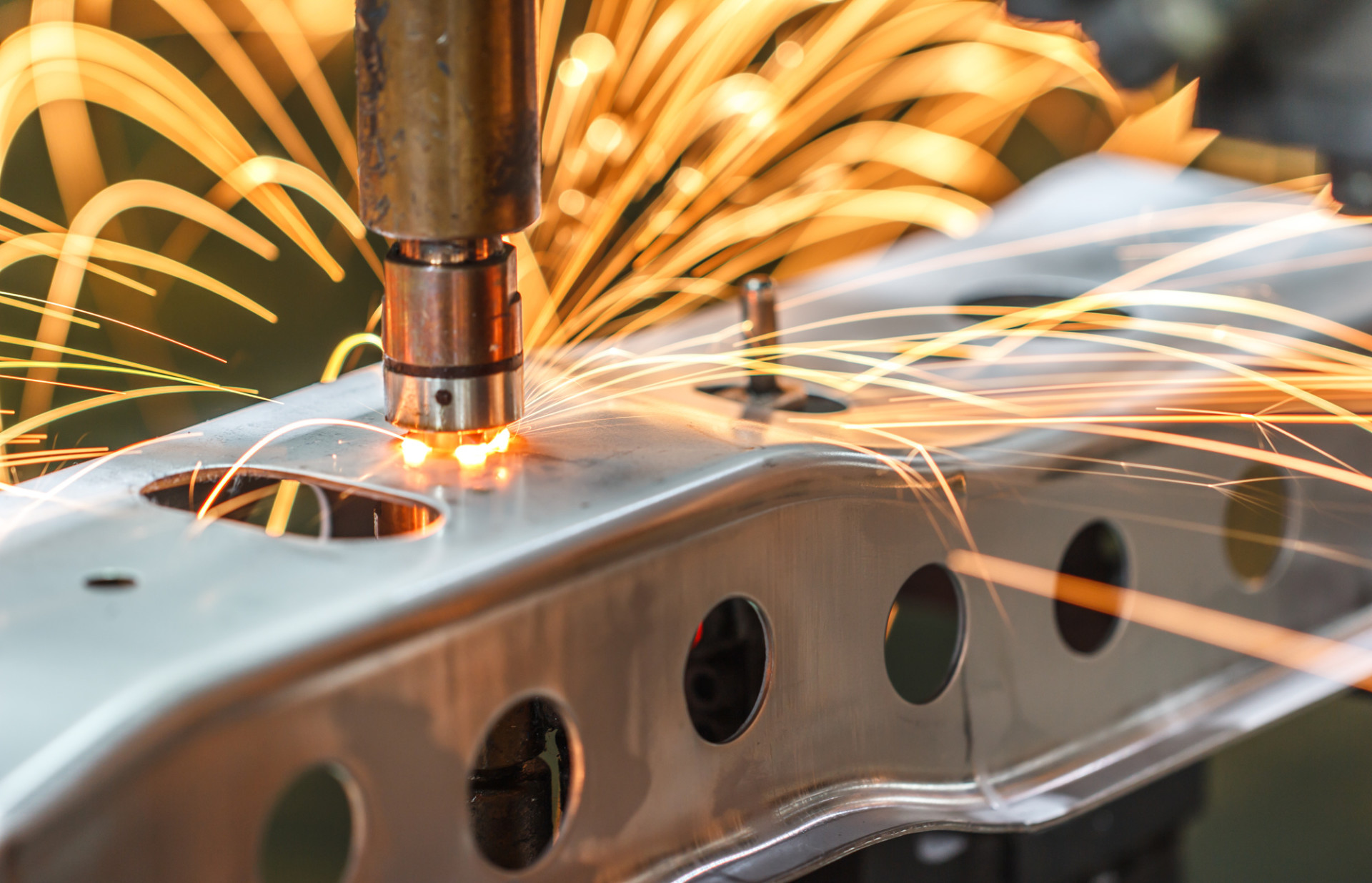

Laser welding has allowed for modern society to thrive. Laser welders are relevant to modern advanced manufacturing which can be automatized to increase your return on investment and overall productivity.

Educating yourself on how welding using lasers works can be beneficial to your business.

Here is a brief guide to modern laser welding and how these machines could revolutionize the way you work.

How Laser Welding Works

Laser beam welding works by harnessing the power of high-power fiber lasers that are continuous or even quasi-continuous. Welding using lasers will require close to an infrared wavelength.

You can easily control the lasers which can change both the resolution and speed that it performs at.

Laser beam welding is applicable for many different types of projects including ones that vary in metal, shape, and size. This makes laser welding machines a very useful tool in modern building.

A demo video of our AWS Laser Welding System

How is it Different from Arc Welding?

Using lasers to weld is different from tradition arc welding.

Fiber lasers are an overall safer system to work with and in many cases are easier to use. Arc welding does come with limitations that aren’t a problem when working with lasers.

Lasers affect smaller areas by their heat which means there is less of a chance of any cracks or damage to the surrounding material like high-carbon steel than when you use an arc welder.

Another difference is that there is an option to use either penetration or conduction welding. This creates more versatility for the welder.

Modern Changes to Revolutionize Your Business

Laser welding is an application that has been used for over half a century in industrial welding. Throughout the years, there have been technological advancements which made laser welders high-functioning multitasking machines.

These powerful machines are now able to cover many different operations in one. You can get a machine that can drill, cut, mark, and weld all in one. If it isn’t all together as one machine, you can find a machine with multiple interchangeable parts for your convenience.

Another thing that has changed is the amount of control you get with newer laser machine welding. They can be much more precise than older models because there is an increased range of processing.

This increase of control will allow you to use the laser on different kinds of materials with needed precision.

Increased Productivity and Return on Investment with Automation

Automated laser welders reduces the need to hire specialists to work the factory floor. The machine is easy enough to be operated by any workers available because of the pre-determined settings.

Another advantage is that the welding process is simplified by using fiber lasers. This will allow you to produce a greater volume of overall product.

If you need to increase your production rate, you can purchase more laser welders. This is an easy way to easily scale up your business.

An Innovative Tool

Automated laser welding systems aid in the manufacturing of new products and designs.

They can change the way you run your business by increasing production and putting money back in your wallet.

Weldlogic designs, manufactures and provides welding solutions for businesses worldwide. These products are high-quality and have a long lifespan of over 25 years.

Take a look at our AWS Laser Welding Power Supply.

![Featured image for “[Engineering Solutions] Automatic G.T.A.W. Welding Made Easy”](https://weldlogic.com/wp-content/uploads/2018/08/IMG_0946-1.jpg)